Light high-efficiency multilayer heat insulation material and preparation method thereof

A multi-layer heat insulation material and heat insulation material technology, applied in the direction of chemical instruments and methods, layered products, flat products, etc., can solve problems such as high cost and complicated process, and achieve improved integrity, toughness, and low thermal conductivity , the effect of high-efficiency heat insulation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

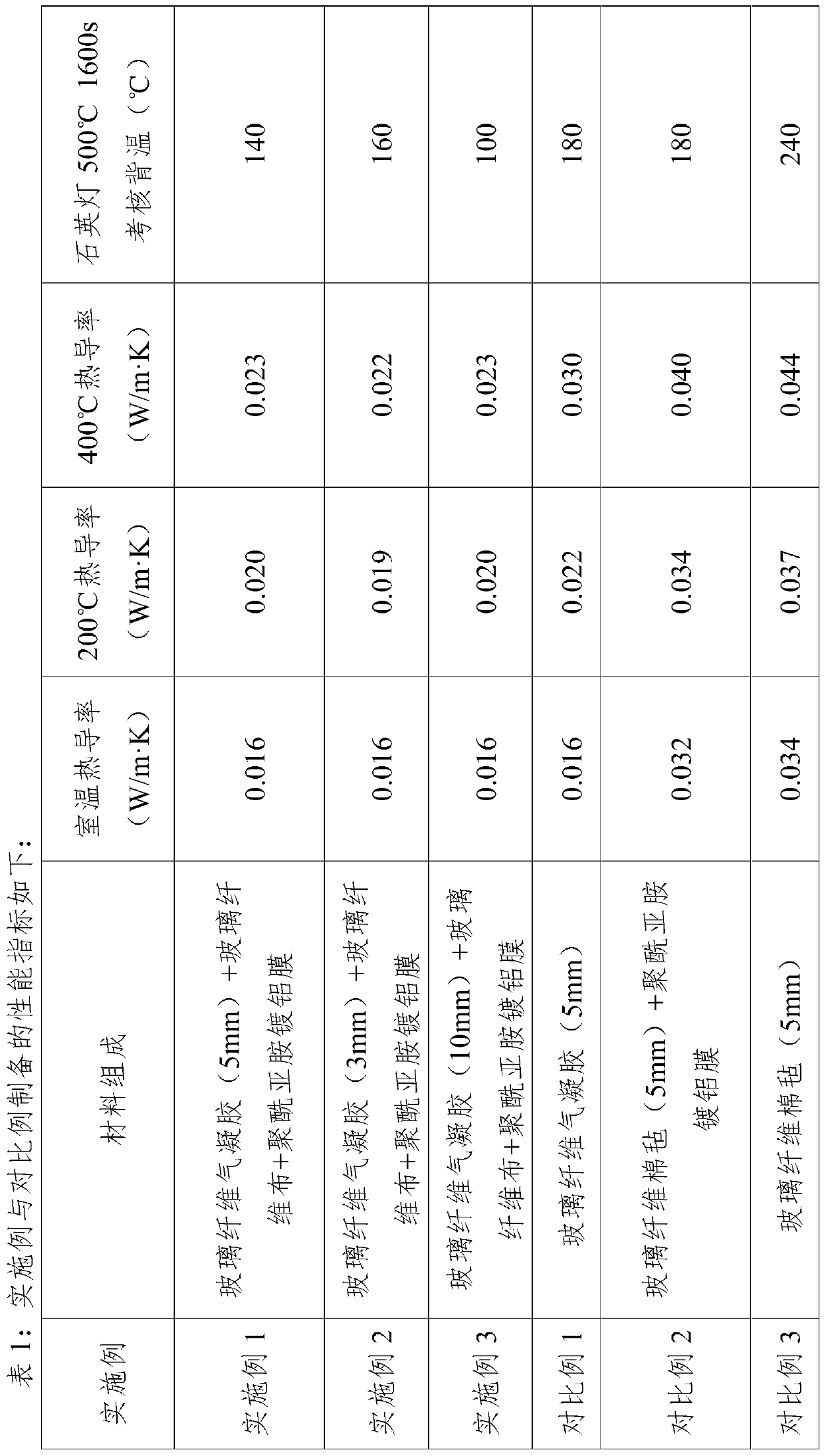

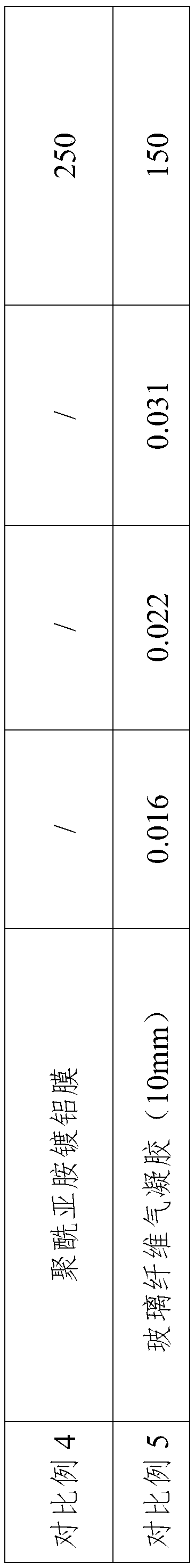

Examples

preparation example Construction

[0029] In a first aspect, the present invention provides a method for preparing a light-weight and high-efficiency multilayer thermal insulation material, the method comprising the following steps:

[0030] (1) The fiber preform is impregnated with the sol to obtain an airgel composite material; the fiber preform is preferably selected from glass fiber, high silica fiber, basalt fiber, quartz fiber, aluminum silicate fiber, alumina fiber and mullite fiber, that is, in the present invention, the fiber preform is preferably made of glass fiber, high silica fiber, basalt fiber, quartz fiber, aluminum silicate fiber, alumina fiber and One or more (two or more) fibers in the mullite fiber; in the present invention, the fiber preform can be made into forms such as cotton felt, needle felt, fiber blanket, etc.; more Preferably, the fiber preform is made of fibers selected from the group consisting of glass fibers (low-cost glass fibers), high silica fibers and basalt fibers; in the p...

Embodiment 1

[0052] The lightweight and high-efficiency multi-layer thermal insulation material used at medium temperature is prepared according to the invention. Airgel uses fiber preforms to impregnate sol precursors at normal temperature and pressure, and is formed by a sol-gel process. The fiber preforms are made of glass fiber mats, and the sol precursors are composed of tetraethyl orthosilicate, solvents, water, and catalysts. The fiber cloth is made of two-dimensional weaving of glass fiber yarn (the linear density of the glass yarn is 30tex, and the twist is 70T / M). The reflective film is made of polyimide aluminized film, and the thickness of the reflective film is 25 μm. KH-CL-RTV room temperature vulcanized silicone rubber adhesive.

[0053] ① Firstly, the glass fiber is mixed and molded into a glass fiber mat (fiber prefabricated body is provided), and then the glass fiber mat is impregnated with a sol precursor composed of tetraethylorthosilicate, solvent, water, and a catalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com