Winding cell and battery

A cell and battery technology, used in non-aqueous electrolyte battery electrodes, battery electrodes, secondary batteries, etc., can solve problems such as capacity loss, positive aluminum leakage, ternary battery safety hazards, etc., to avoid safety hazards and prevent precipitation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] During the production and processing of the battery pole pieces, the tabs need to be cut, and the cut tabs need to be marked with Mark holes, so that a depression will be cut at the top of the tabs to provide for the subsequent winding process. Identification mark.

[0035] In the original winding process, a gluing device is added for gluing.

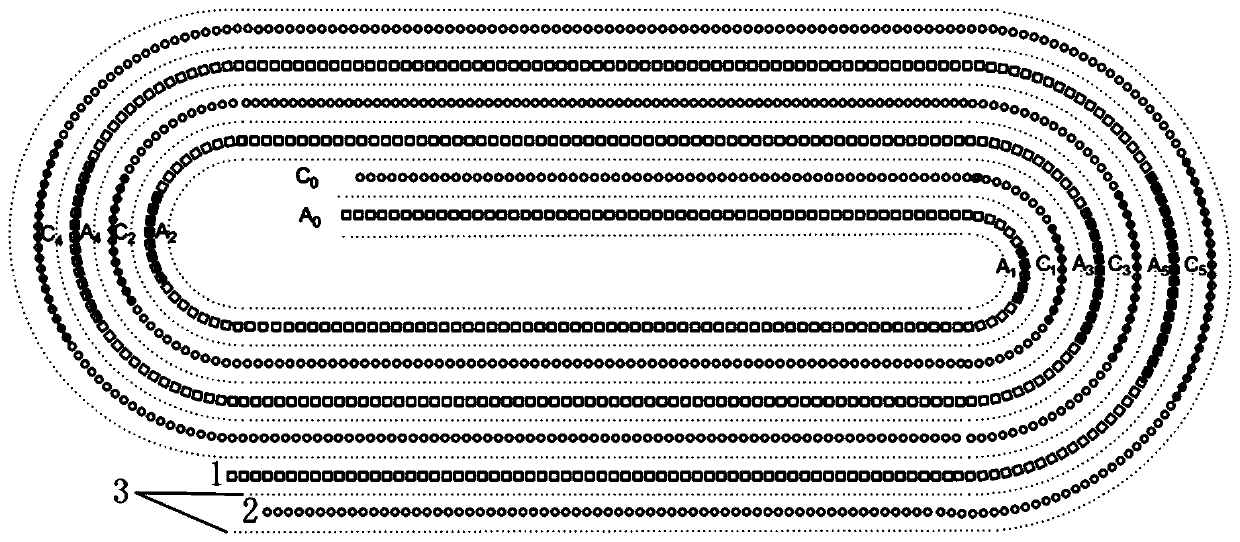

[0036] A method to improve the safety performance of winding batteries, including the positive and negative pole pieces are rolled and then passed through a slitting die-cutting machine to cut the tabs, and after the hardware or laser die-cutting machine has punched the Mark hole, pass With the added gluing device, the equipment pulls the positive and negative pole pieces to move, and glues on the corresponding position. Assume that the circumference of the winding needle is 250mm when the battery is designed, and the position of the positive electrode is C 0 30mm, negative electrode entry position A 0 It is 15mm (that is, the...

Embodiment 2

[0039] A method for improving the safety performance of wound batteries, comprising the steps of rolling the positive and negative pole pieces through a slitting die-cutting machine to cut tabs, and then performing a second slitting after the tabs are cut. A gluing device is added to the strip, the equipment pulls the positive and negative poles to move, and glues on the corresponding position, and the distance from the Mark position of the positive gluing is C 1 , C 2 , C 3 ...C 2N ; Negative electrode sheet glue is completed by negative electrode die-cutting machine, and the distance between the glue and the Mark position is A 1 , A 2 , A 3 ...A 2N , The number of laps of glue application can be controlled by manually opening or closing the glue application mechanism at regular intervals, or it can be automatically controlled by machine program to control the quantity of glue application. Through the adjustment of the device on the secondary slitting machine, you can c...

Embodiment 3

[0041] A method for improving the safety performance of winding batteries, including the positive and negative electrode pieces are rolled and then passed through a slitting die-cutting machine to cut the tabs, and the hardware or laser die-cutting machine punches the mark holes, and then cuts the tabs. Secondary split. During the loading process of the winding machine, through the gluing mechanism on the winding machine, the distance between the positive electrode gluing position and Mark is C 1 , C 2 , C 3 ...C 2N ; The distance from Mark to the position of the negative electrode sticker is A 1 , A 2 , A 3 ...A 2N , The number of laps of glue application can be controlled by manually opening or closing the glue application mechanism at regular intervals, or it can be automatically controlled by machine program to control the quantity of glue application. Through the adjustment of the device on the winding machine, you can choose to paste the positive and negative pole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com