Lithium ion battery lamination unit, battery cell, battery cell preparing method and lithium ion battery

A lithium-ion battery and lamination technology, applied in the field of lithium-ion batteries, can solve the problems of low production efficiency, unable to meet the production needs of lithium-ion power batteries, etc., and achieve the advantages of improving production efficiency, saving production time, and improving the qualified rate of finished products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The lithium-ion battery laminated unit of this embodiment is a positive electrode laminated unit or a negative electrode laminated unit;

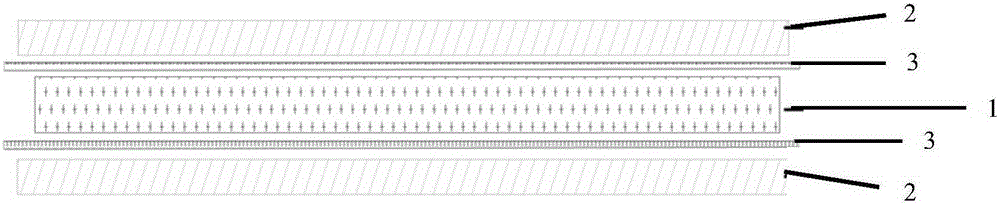

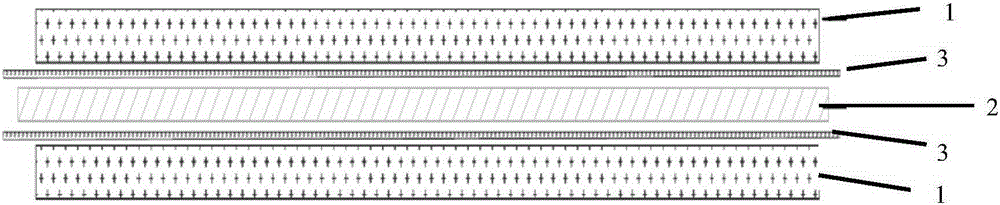

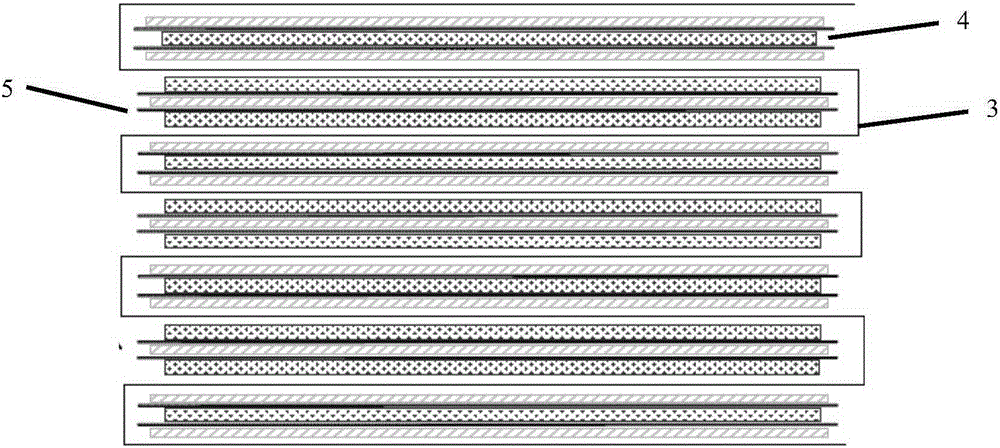

[0038] Such as figure 1 As shown, the positive electrode stack unit is composed of a positive electrode sheet 1, a separator 3 and a negative electrode sheet 2. The two sides of the positive electrode sheet 1 are respectively bonded with a separator 3 by an adhesive, and the outer surface of the separator 3 on each side is A negative electrode sheet 2 is bonded by a binder; as figure 2 As shown, the negative electrode laminate unit is composed of a negative electrode sheet 2, a separator 3 and a positive electrode sheet 1. The two sides of the negative electrode sheet 2 are respectively bonded with a separator 3 by an adhesive, and the outer surface of the separator 3 on each side is The positive electrode sheet 2 is bonded by a binder;

[0039] The positive electrode sheet 1 is composed of aluminum foil and the positive electrode...

Embodiment 2

[0053] The lithium-ion battery laminated unit of the present embodiment is a positive pole laminated unit or a negative pole laminated unit; Diaphragm, the outer surface of the diaphragm on each side is bonded with a negative electrode sheet by an adhesive; the stacked sheet unit is composed of a negative electrode sheet, a separator and a positive electrode sheet, and the two sides of the negative electrode sheet are bonded by an adhesive There is a separator, and the outer surface of the separator on each side is bonded with a positive electrode sheet through an adhesive;

[0054] The positive electrode sheet is composed of aluminum foil and the positive electrode active material layer coated on both sides of the aluminum foil. The thickness of the positive electrode sheet is 120 μm. The negative electrode sheet is composed of copper foil and the negative electrode active material layer coated on both sides of the copper foil. The thickness of the negative electrode sheet is ...

Embodiment 3

[0068] The lithium-ion battery laminated unit of the present embodiment is a positive pole laminated unit or a negative pole laminated unit; Diaphragm, the outer surface of the diaphragm on each side is bonded with a negative electrode sheet by an adhesive; the stacked sheet unit is composed of a negative electrode sheet, a separator and a positive electrode sheet, and the two sides of the negative electrode sheet are bonded by an adhesive There is a separator, and the outer surface of the separator on each side is bonded with a positive electrode sheet through an adhesive;

[0069] The positive electrode sheet is composed of aluminum foil and the positive electrode active material layer coated on both sides of the aluminum foil. The thickness of the positive electrode sheet is 120 μm. The negative electrode sheet is composed of copper foil and the negative electrode active material layer coated on both sides of the copper foil. The thickness of the negative electrode sheet is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com