A coiling lithium secondary battery

A lithium secondary battery, wound-type technology, applied in the high-energy field, can solve problems such as short circuit of positive and negative electrodes, hidden dangers of battery safety, short circuit of battery, etc., to prevent powder drop, improve battery yield rate, and avoid internal micro short circuit of battery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

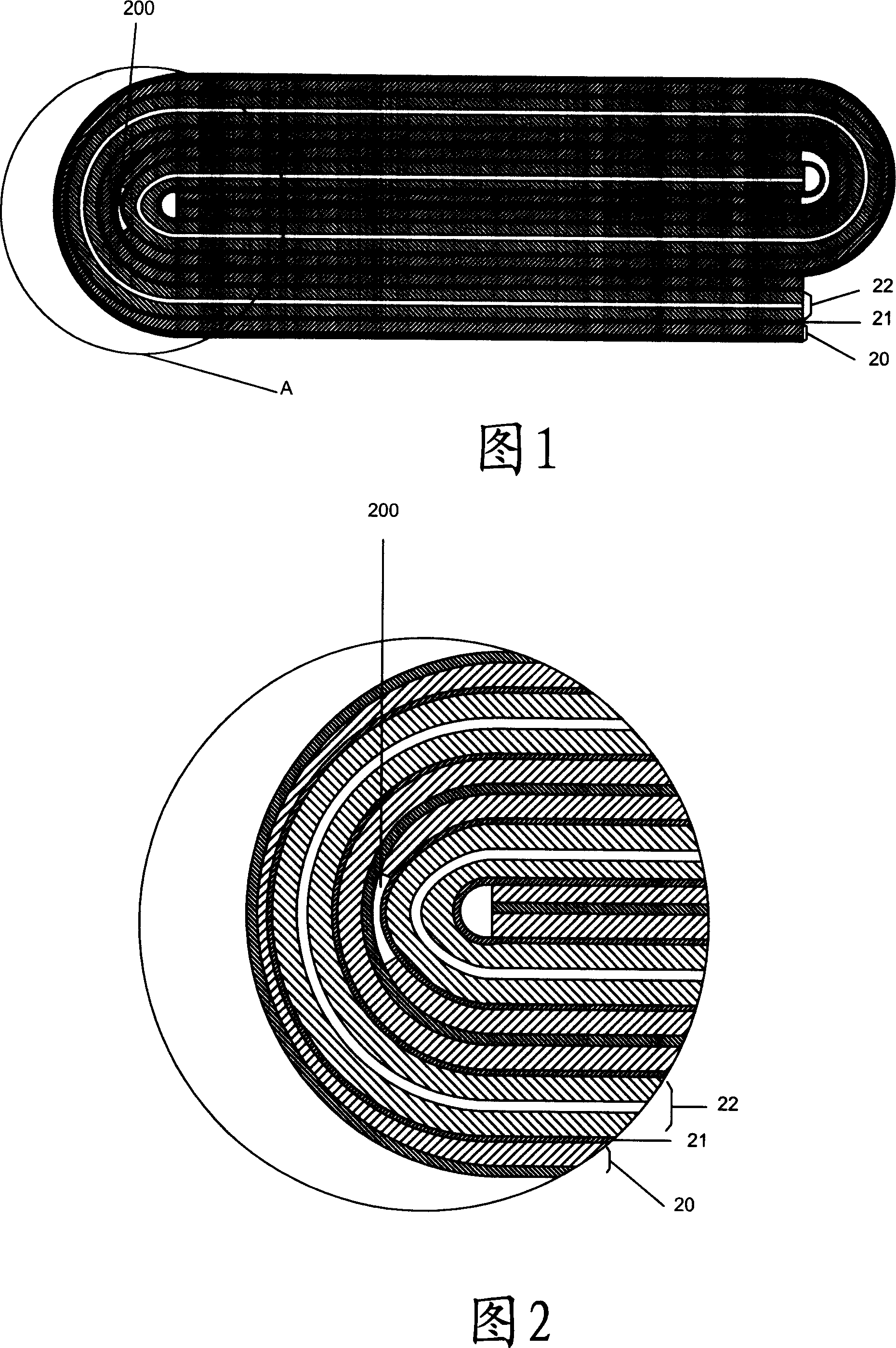

[0014] A winding type lithium secondary battery, which comprises a case, a cell winding body and an electrolytic solution accommodated in the case. As shown in Figure 1, the battery winding body is wound by a positive electrode sheet 20, a separator 21, and a negative electrode sheet 22. There is a width of 2 mm inside the positive electrode sheet at the bend of the battery winding body, and the length is equal to the width of the positive electrode sheet. The region is not coated with the active material layer 200, and the present invention can be understood more clearly through the enlarged view of A in FIG. 1 in FIG. 2 .

Embodiment 2

[0016] This embodiment is basically the same as Embodiment 1, except that the width of the uncoated active material layer is 1.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com