Negative ion gypsum-based putty powder and preparing method

A negative ion powder, gypsum-based technology, applied in the field of building wall decoration materials, to achieve the effect of improving lung capacity, enhancing human immunity, and good suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

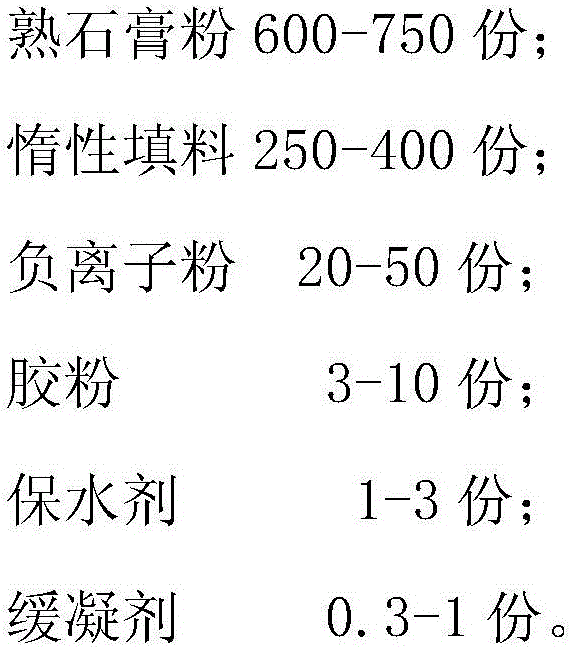

[0036] A kind of negative ion gypsum base full batch powder of the present invention is realized in this way, and its formula comprises by weight proportioning:

[0037] A kind of negative ion gypsum-based full-batch powder is characterized in that the formula comprises by weight:

[0038] 600 parts of Paris plaster powder;

[0039] 250 parts of inert filler;

[0040] Negative ion powder 20 parts;

[0041] 3 parts rubber powder;

[0042] 1 part water retaining agent;

[0043] 0.3 parts of retarder.

[0044] in,

[0045] The plaster of paris is high-quality hemihydrate gypsum powder, including one or both of α-type high-strength hemihydrate gypsum and / or β-type high-quality hemihydrate desulfurized gypsum, and its fineness is required to be ≤300 mesh standard sieve.

[0046] The inert filler is one or more mixtures of talcum powder, heavy calcium carbonate, light calcium carbonate, montmorillonite powder, kaolin and / or bentonite.

[0047] The negative ion powder is mainl...

Embodiment 2

[0050] A method for preparing negative ion gypsum-based full-batch powder is characterized in that it comprises the following steps: according to the formula weight ratio,

[0051] 750 parts of Paris plaster powder;

[0052] 400 parts of inert filler;

[0053] Negative ion powder 50 parts;

[0054] 10 parts of rubber powder;

[0055] 3 parts of water retaining agent;

[0056] 1 part retarder.

[0057] The plaster of paris is α-type high-strength hemihydrate gypsum and β-type hemihydrate desulfurized gypsum, and its fineness is required to be ≤300 mesh standard sieve.

[0058] The inert filler is one or more mixtures of talcum powder, heavy calcium carbonate and / or kaolin and bentonite.

[0059] The negative ion powder is mainly composed of nano-vermiculite powder and tourmaline, mixed with attapulgite and one or more rare earth elements such as cerium oxide, neodymium oxide, terbium oxide and / or lanthanum oxide. The mixing ratio is For: nano vermiculite powder: tourmalin...

Embodiment 3

[0062] Embodiment 3: a kind of negative ion gypsum base full batch powder, comprises the raw material of following weight portion:

[0063] 650 parts of Paris plaster powder;

[0064] 350 parts of talcum powder;

[0065] Negative ion powder 20 parts;

[0066] 5 parts of rubber powder;

[0067] 2 copies of CMC;

[0068]0.4 parts of retarder.

[0069] in,

[0070] The plaster of paris is hemihydrate gypsum powder, and its fineness requirement is ≤300 mesh standard sieve.

[0071] The inert filler is one or more mixtures of light calcium carbonate, montmorillonite powder and / or kaolin and bentonite.

[0072] The negative ion powder is mainly composed of nano-vermiculite powder and tourmaline, mixed with one or more rare earth elements such as attapulgite and lanthanum oxide, and the mixing ratio is: nano-vermiculite powder: tourmaline: attapulgite Earth: rare earth elements = 30:30:10:10, the average particle size distribution of mixed negative ion powder is required to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com