Multi-functional ceramic weaving and carving machine and control system thereof

A kind of engraving machine, multi-functional technology, applied in the direction of engraving, decorative art, processing models, etc., can solve the problems of many materials, messy placement, etc., and achieve the effect of reducing burden, placing orderly, and reducing occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are now described in detail with accompanying drawings as follows. The embodiments described in the accompanying drawings are only used to illustrate the technical solutions of the present invention and are not limiting this invention.

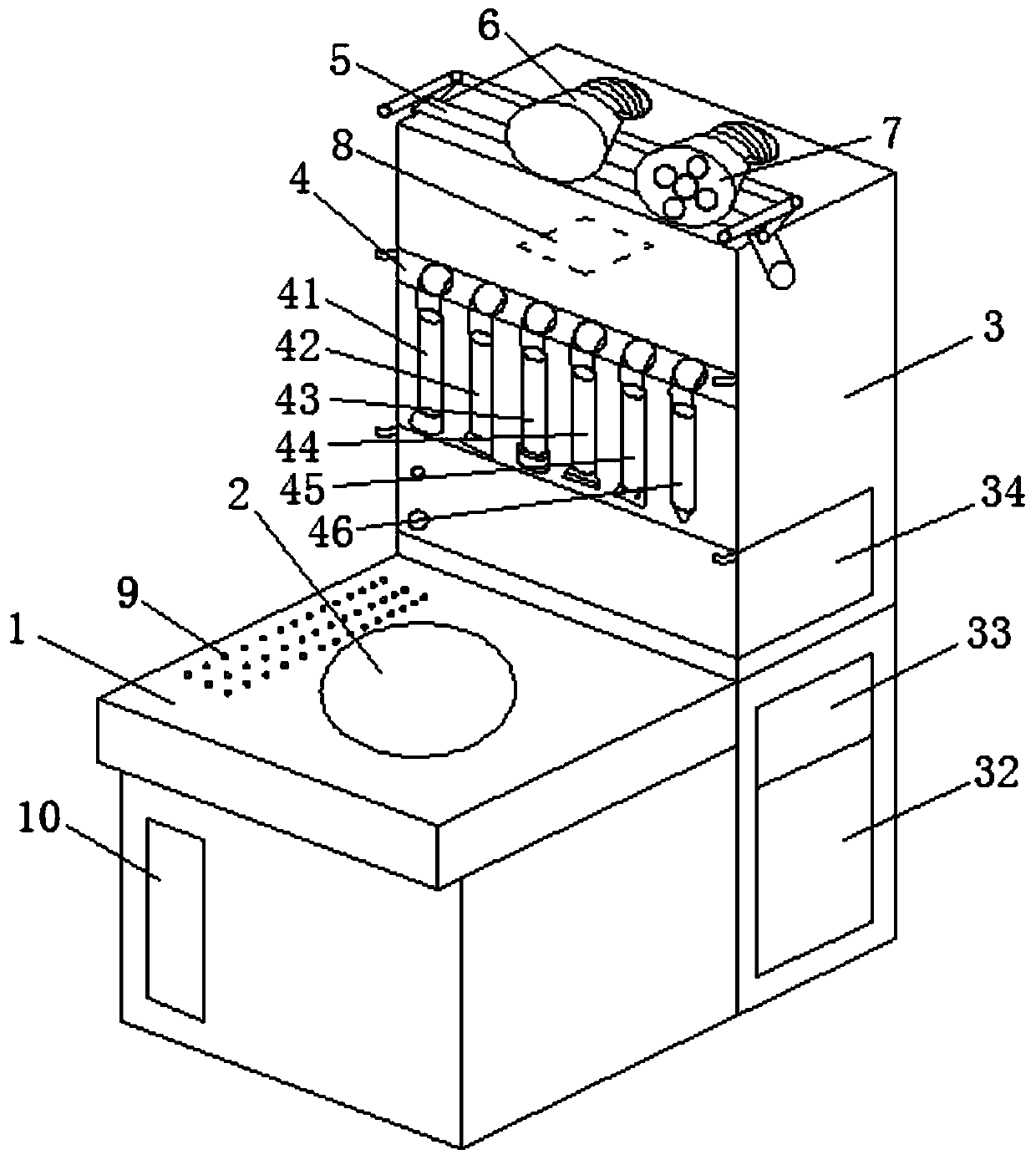

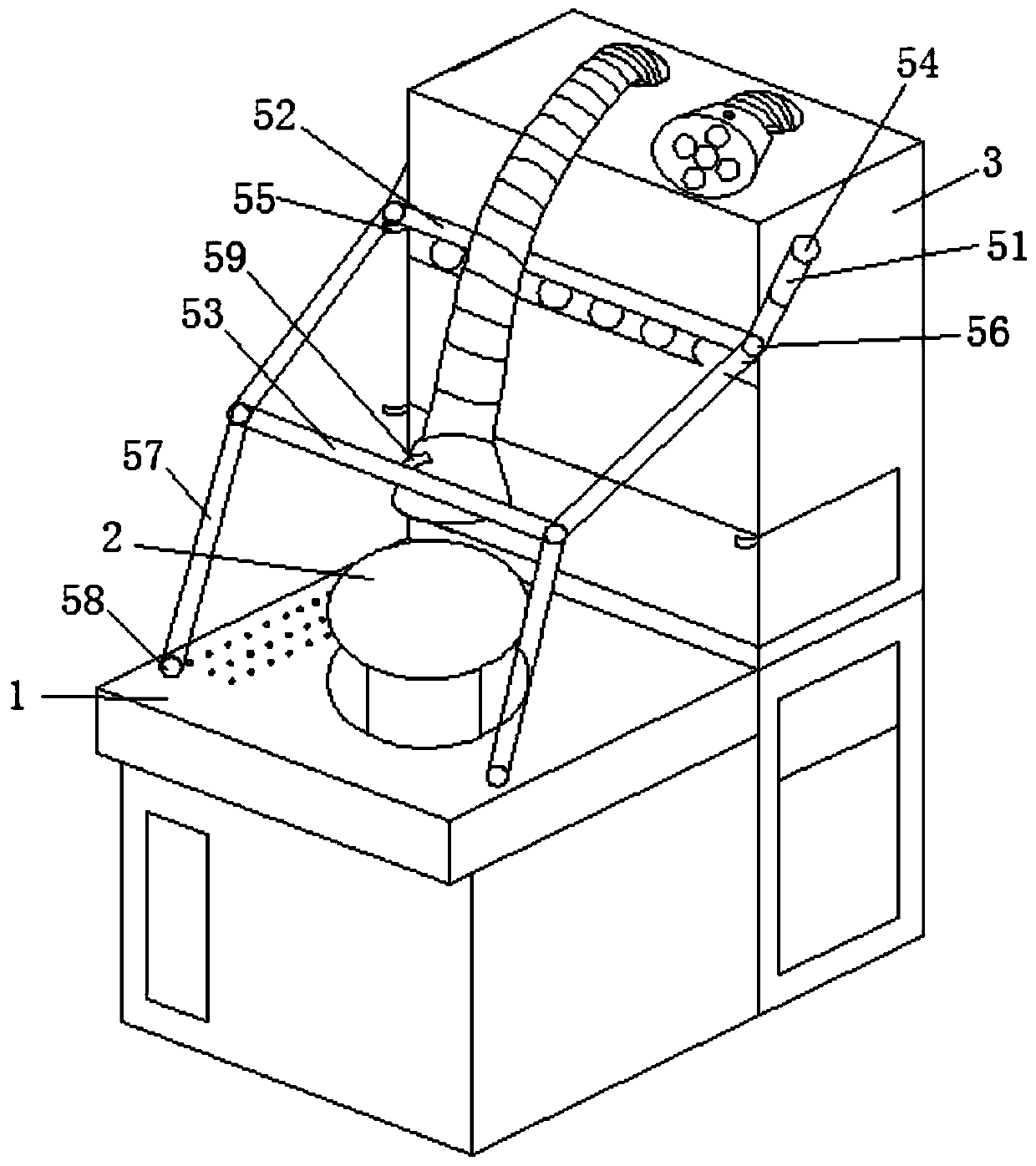

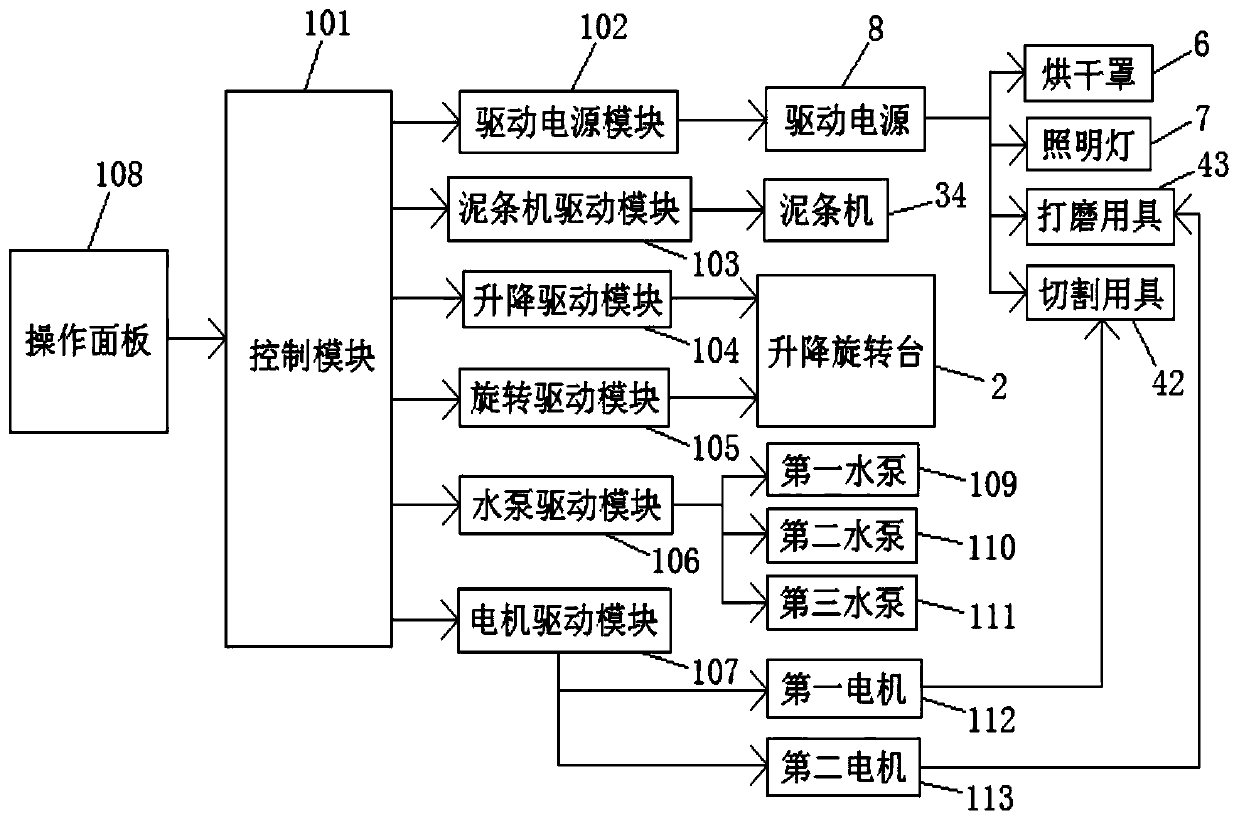

[0018] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the multifunctional porcelain engraving machine of the present invention; the multifunctional porcelain engraving machine includes a workbench 1, a lifting and rotating table 2 embedded in the middle of the workbench 1, and a body 3 erected behind the workbench 1; Wherein, the left side of the bottom of the body 3 is provided with a water tank 31, the right side of the bottom of the body 3 is provided with a glaze box 32 and a color material box 33, and the middle part of the body 3 is provided with a slime machine 34; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com