Sockes and production method thereof

A technology for socks and heels, which is applied in the field of socks and their manufacturing, can solve the problems of color difference, missing needles, and easy thread opening, and achieves the effects of excellent appearance and durability, improved knitting efficiency, and improved productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

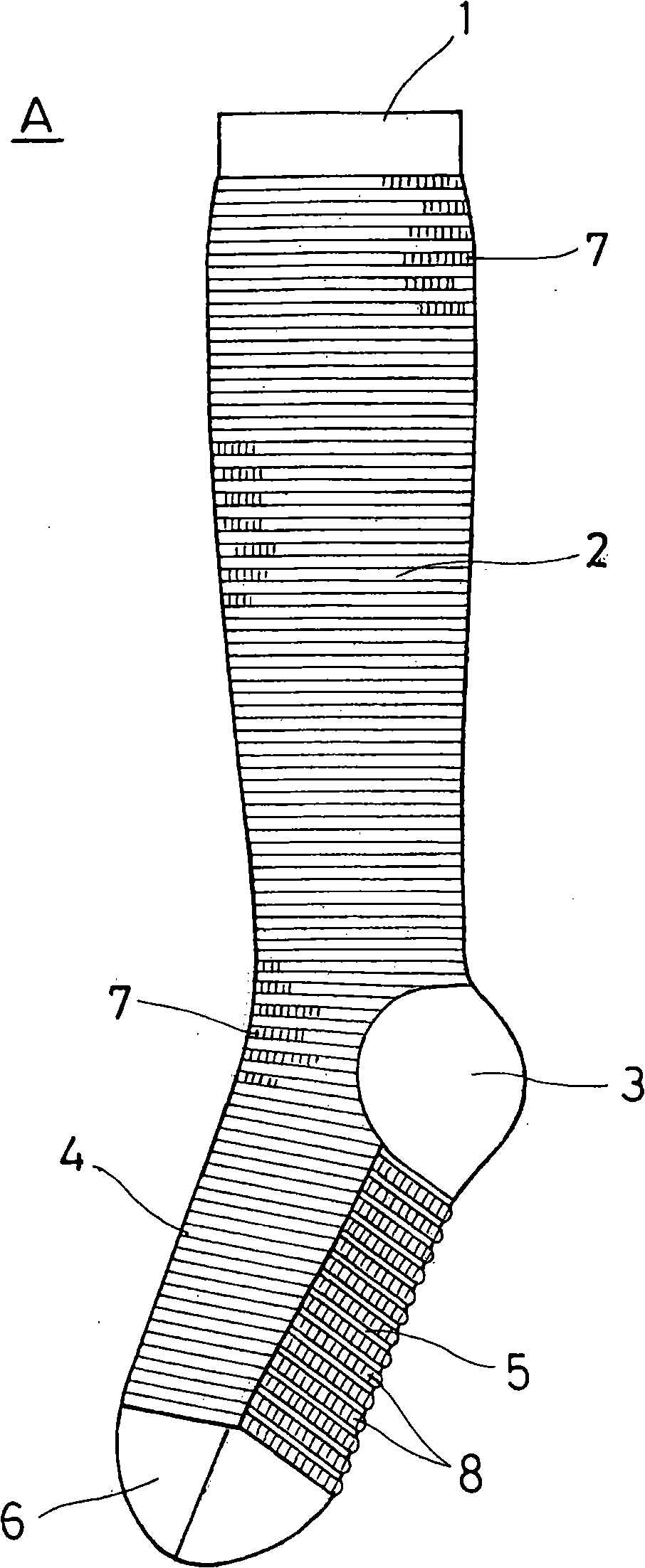

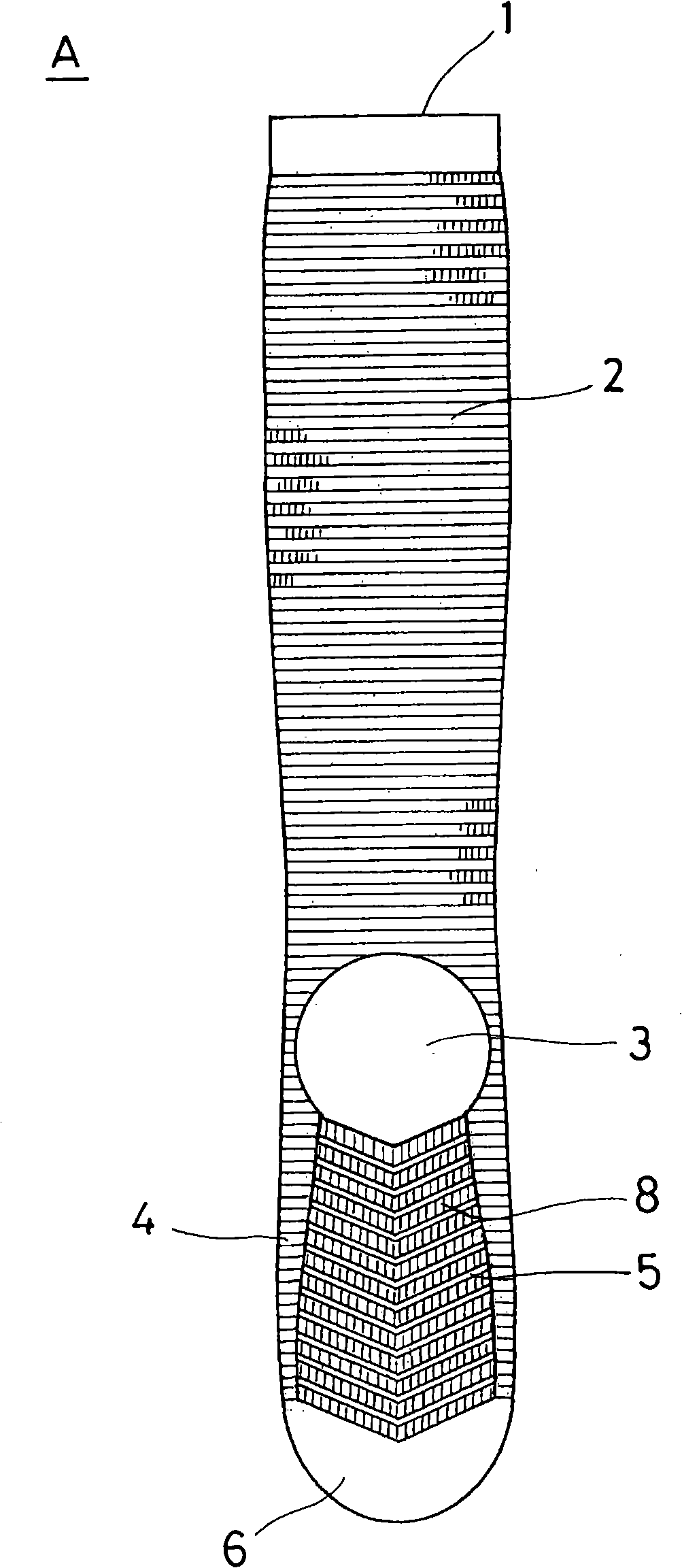

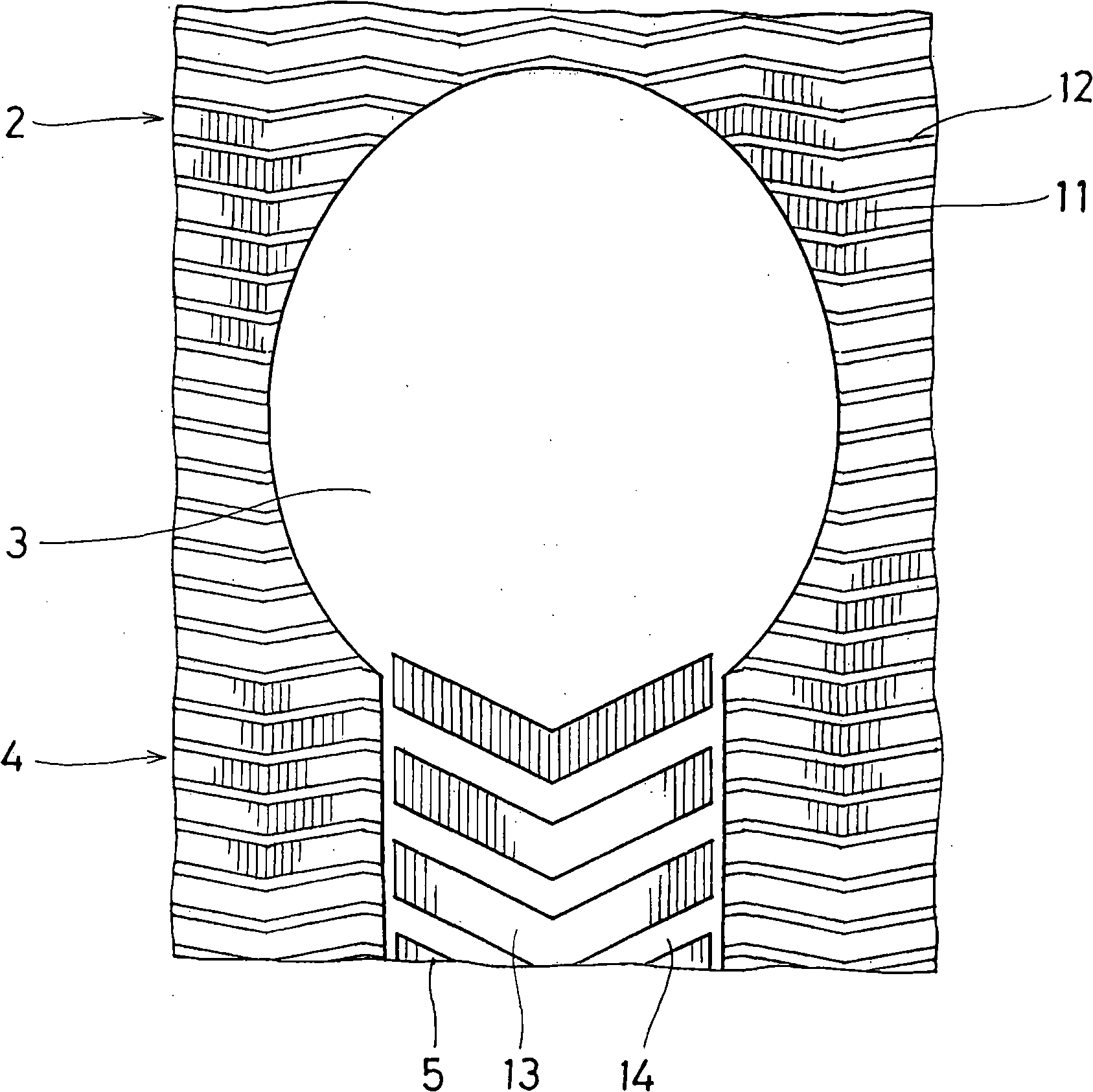

[0041] Embodiments of the present invention are described below with reference to the accompanying drawings. figure 1 It is a schematic side view of a sock showing an embodiment of the present invention. figure 2 It is a rough front view viewed from the sole side of the socks in the above figure. image 3 It is an enlarged tissue diagram of the region around the heel of the sock of the present invention. Figure 4 It is a schematic side view showing another embodiment of the present invention. Figure 5 It is an explanatory diagram of the weaving in the case of weaving piqué yarn. Image 6 It is an organization explanatory diagram of a continuous floating line organization.

[0042] The sock A of the illustrated embodiment represents a sock, and reference numeral 1 in the figure represents an opening at the upper end of the entrance, 2 is a leg portion, 3 is a heel portion, 4 is an instep portion, and 5 is a foot portion. sole, 6 is the head.

[0043] The sock A is basi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com