Design for fur / leather weaving products based on computer aided design and production method thereof

A computer-aided technology for woven products, applied in computing, special data processing applications, instruments, etc., can solve the problems of insufficient design strength and single variety of leather/leather woven products, and achieve easy mastery, rich patterns and convenient innovative design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 Synthetic leather woven wallet, the operation steps are as follows:

[0049] 1. Make a weaving diagram

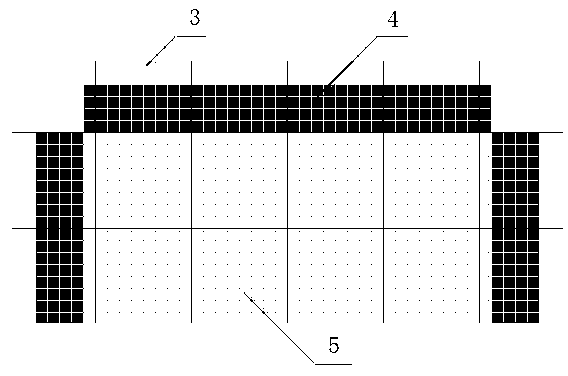

[0050] (1) This embodiment adopts the normal weaving design: input the contour shape of the wallet into the computer, and add it according to the requirements of weaving and sewing on the computer to obtain figure 2 The outline shape of the wool sample is shown. Add length=24.6mm×2;

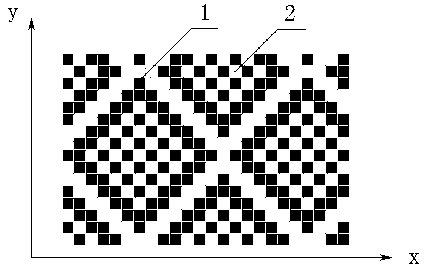

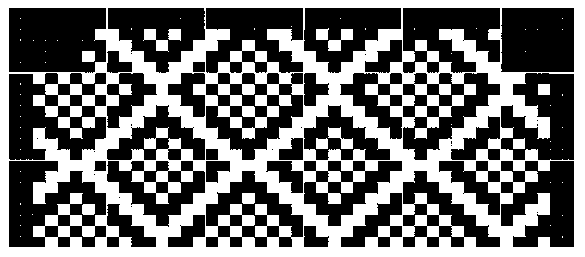

[0051] (2) Operate the computer to spread the diamond-shaped twill pattern with the cycle size of Rj×Rw=14×14 into the outline of the wool sample, such as image 3 ;

[0052] (3) In the fabric CAD software, input the specification parameters of the wallet wool sample outline: length = 266mm, width = 124mm, leather strip width = 6mm, warp leather strip arrangement density = weft leather strip arrangement density = 162 / m. The number of warp leather strips = 43, and the weft leather strips = 40. Correct the initial weaving pattern made in step (2) so that the pattern is co...

Embodiment 2

[0059] Example 2 To make a three-piece set of leather cushions, three cushions I, II, and III of the same specification were woven from three kinds of fabrics, wherein cushions I and II were weaved, and cushion III was weaved. The operation steps are as follows:

[0060] 1. Make a weaving diagram

[0061] (1) Input the contour shape of the cushion into the computer, and add it according to the requirements of weaving and sewing on the computer, and get Image 6 The outline shape of the wool sample is shown. Add length=10mm×2;

[0062] (2) Operate the computer, spread the reed mat twill into the wool-like outline of the cushion Ⅰ, and obtain the initial weaving diagram of the cushion Ⅰ as follows: Figure 7 As shown; the 2 upper and 2 lower right twill patterns are laid into the wool-like outline of the cushion II, and the initial weaving diagram of the cushion II is obtained as follows Figure 8 As shown; operate the computer, use the fabric CAD software to rotate the wool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com