Cable-cutting and printing all-in-one machine and operating method thereof

An all-in-one machine and printing technology, applied in the direction of marking conductors/cables, etc., can solve the problems of high production costs, low work efficiency, scrapped wires, etc., achieve the effect of reducing material usage and manufacturing costs, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

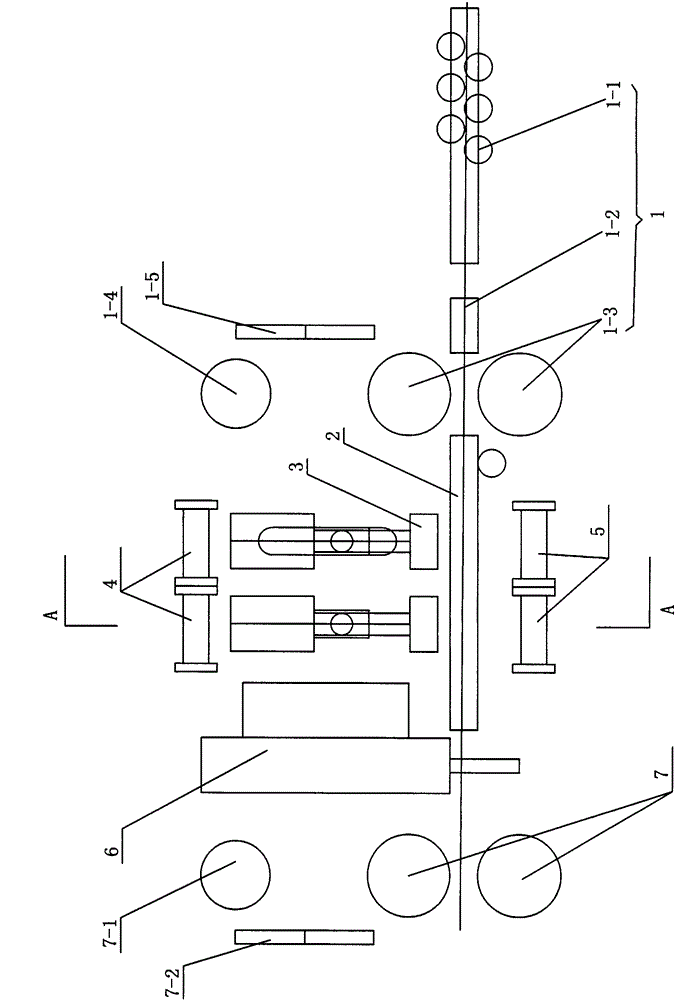

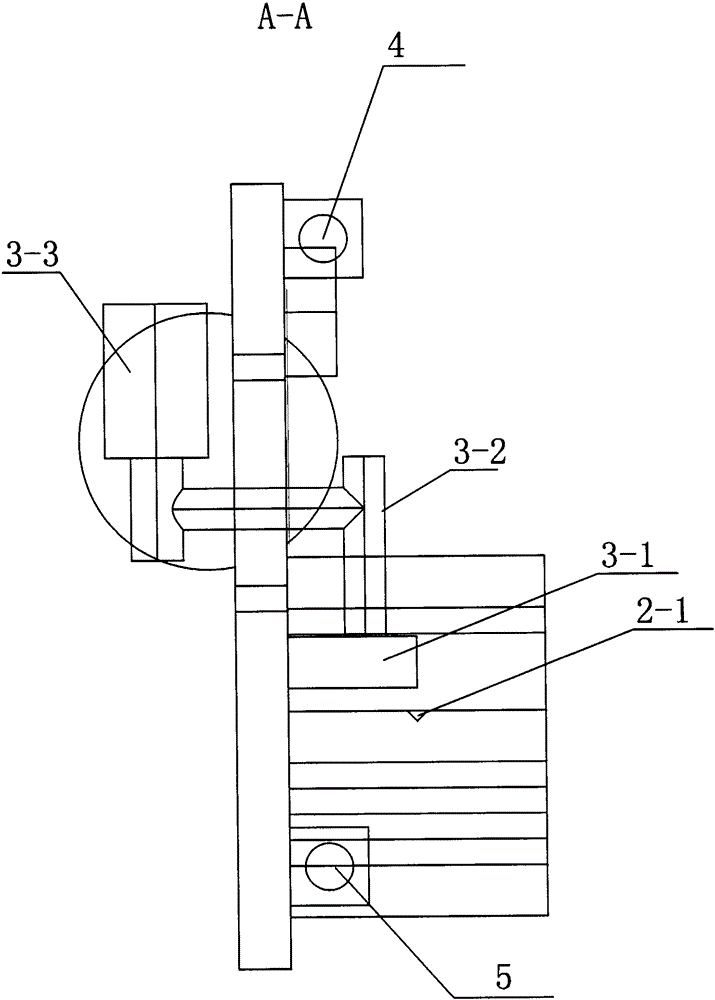

[0024] See figure 1 and figure 2 , an all-in-one machine for disconnection printing, comprising: a feeding mechanism 1 for conveying cables, a printing table 2 arranged at the rear end of the feeding mechanism 1, a lettering module 3 arranged above the printing table 2 and capable of moving up and down and printing Ribbon unwinding mechanism 4 , printing ribbon rewinding mechanism 5 arranged under the printing table 2 , and disconnecting mechanism 6 arranged at the rear end of the printing table 2 for cutting cables. Use the engraving module to print on the end of the cable, no waste of wires, the printing function is on the side of the cutter holder of the disconnecting machine, which can improve efficiency and reduce material usage and manufacturing costs, avoiding the use of number tubes or heat shrinkable tubes on wires and cables The model number of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com