Simplified Router with Straight Guide Rod

Technology of an engraving machine, guide bar, applied in the field of systems for cutting or engraving flat plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

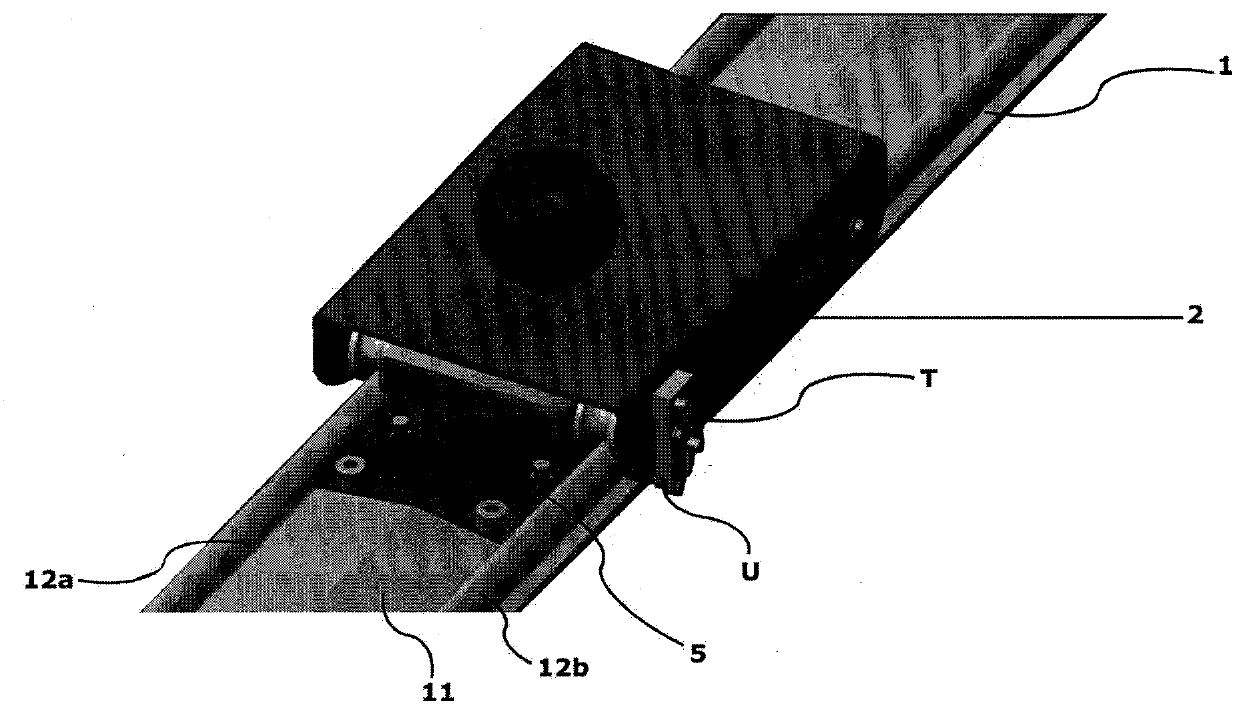

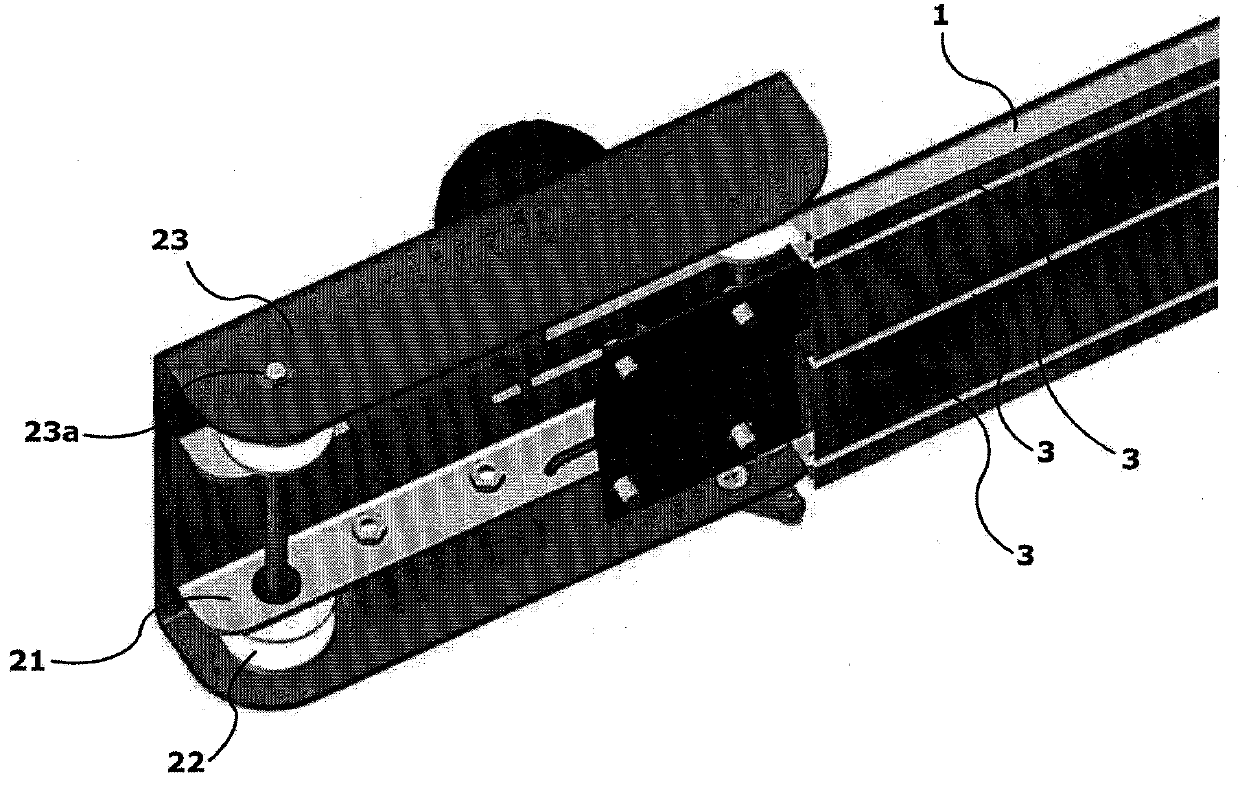

[0032] figure 1 A general view of the engraving device according to the invention is shown.

[0033] The device comprises a guide bar 1 supporting a sliding carriage 2 with a tool holder.

[0034] The guide bar 1 comprises a substantially flat lower portion 11 on which a pair of rails 12a and 12b are provided. Preferably, the guide rod 1 is integrally made of extruded metal material, such as aluminum alloy.

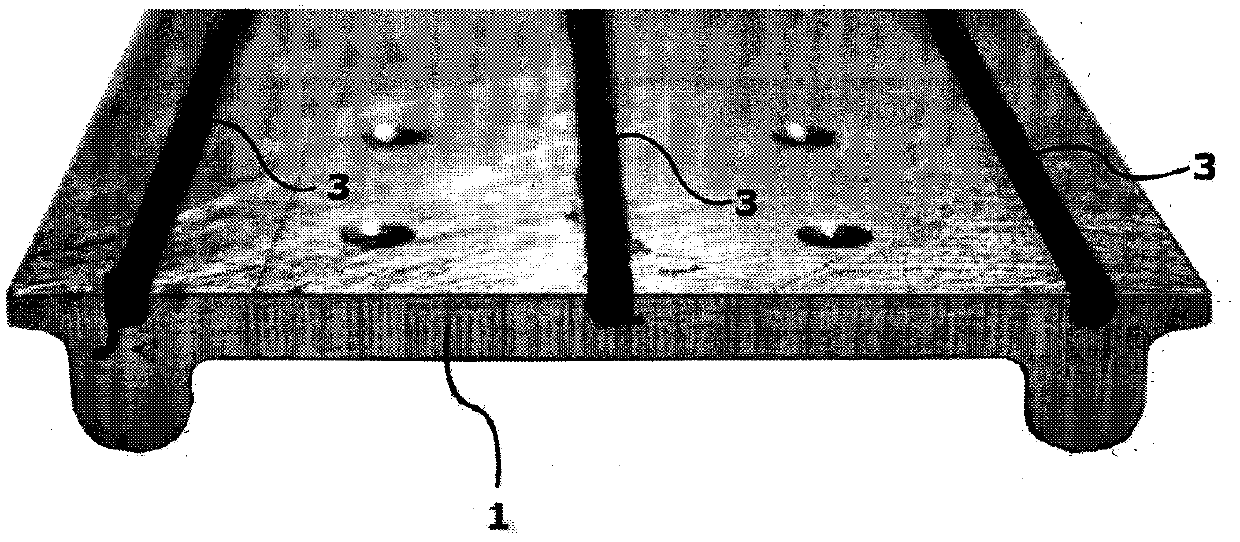

[0035] According to a main aspect of the invention, in the lower part of the guide rod 1 , ie in the surface facing the plate to be engraved, there are deformable support means made of high friction material. In particular, these support means are made of rubber thick enough to be sufficiently compressed using the technique shown below and thus capable of exerting a high frictional resistance to prevent movement of the guide rod 1 on the support plane.

[0036] These deformable supports are not simply scratch-resistant thin layers or coating materials, but the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com