Black ceramic and preparation method thereof

A black porcelain and pulping technology, which is applied in the field of ceramics, can solve the problems of porcelain strength, hardness, difficulty in use and high brittleness when carved into handicrafts, and achieve the effect of not easy to crack, easy to crack, and low brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

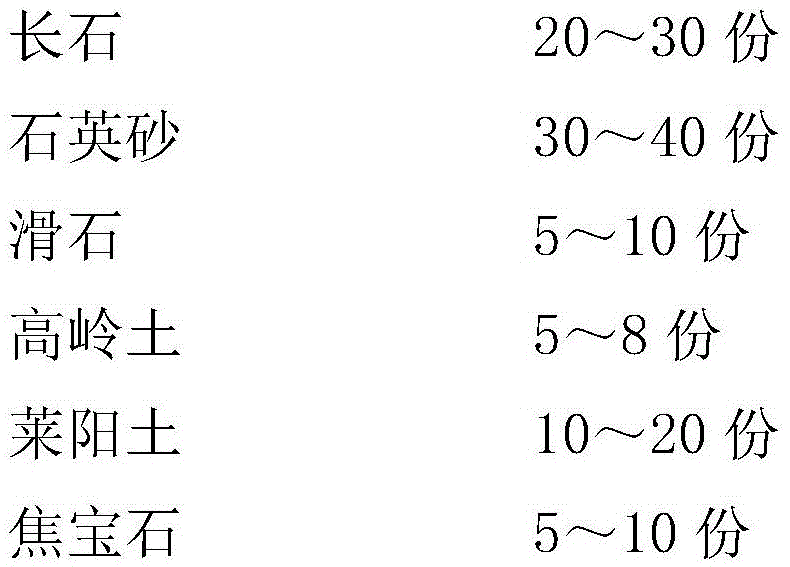

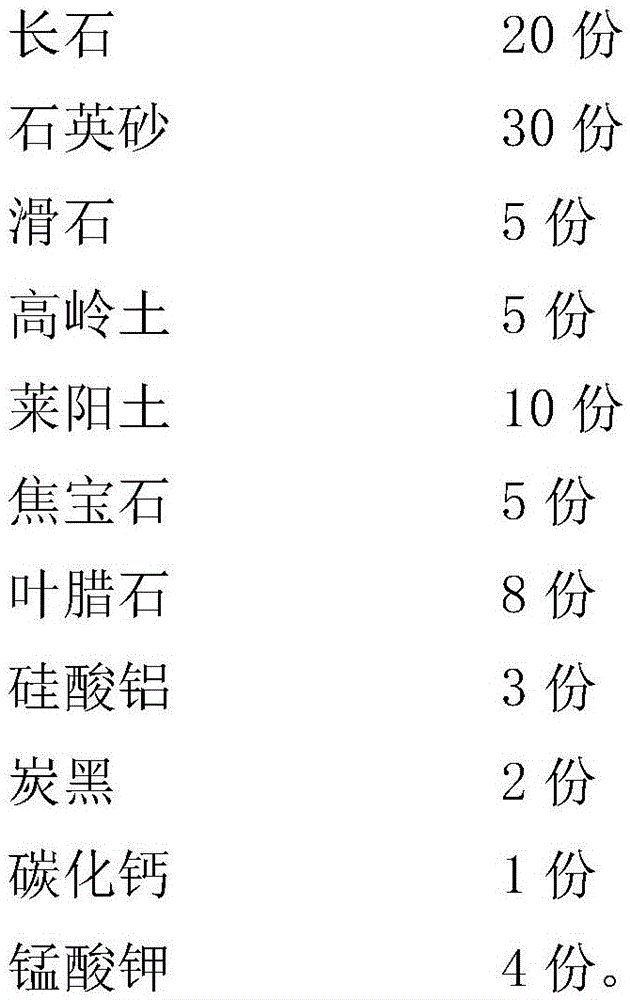

[0023] A kind of black porcelain, made of the following raw material components by weight,

[0024]

[0025] A preparation method of black porcelain, comprising the following steps,

[0026] 1) pulping, the raw materials are distributed according to the group and go through the steps of ball milling, sieving, iron removal and pool storage, and then make slurry;

[0027] 2) making a mold, using gypsum powder to cast and form a gypsum mold for producing ceramics;

[0028] 3) Forming and pouring, through grouting, grouting and demoulding into the plaster mold, and then trimming and production of semi-finished green bodies;

[0029] 4) The sintered and glazed semi-finished products are products formed after high-temperature firing in the kiln. The firing time is 17 hours to 20 hours, and the firing temperature is 1210 ° C to 1290 ° C;

[0030] 5) Inspection.

[0031] The sintering process is performed twice, the first sintering temperature is 800-1100°C, the duration is 8-10...

Embodiment 2

[0034] A kind of black porcelain, made of the following raw material components by weight, 25 parts of feldspar, 35 parts of quartz sand, 80 parts of talc, 6 parts of kaolin, 15 parts of Laiyang clay, 8 parts of burnt gemstone, 12 parts of pyrophyllite, silicic acid 5 parts of aluminum, 3 parts of carbon black, 2 parts of calcium carbide and 5 parts of potassium manganate.

[0035] A preparation method of black porcelain, comprising the following steps,

[0036] 1) pulping, the raw materials are distributed according to the group and go through the steps of ball milling, sieving, iron removal and pool storage, and then make slurry;

[0037] 2) making a mold, using gypsum powder to cast and form a gypsum mold for producing ceramics;

[0038] 3) Forming and pouring, through grouting, grouting and demoulding into the plaster mold, and then trimming and production of semi-finished green bodies;

[0039] 4) The sintered and glazed semi-finished products are products formed after ...

Embodiment 3

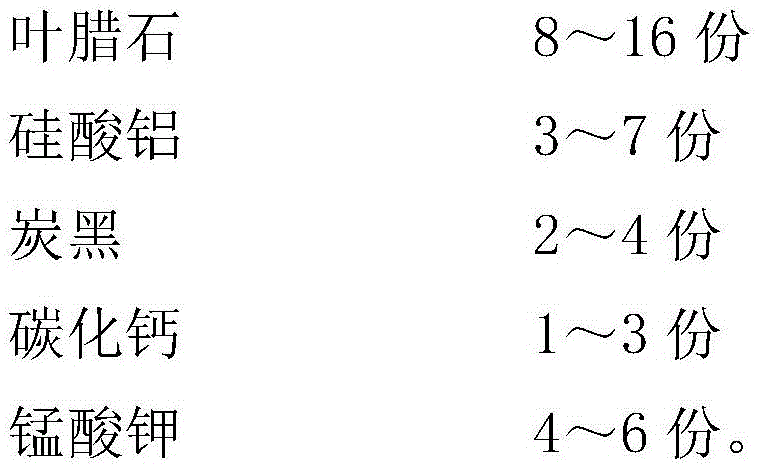

[0045] A kind of black porcelain, made of the following raw material components by weight,

[0046]

[0047] A preparation method of black porcelain, comprising the following steps,

[0048] 1) pulping, the raw materials are distributed according to the group and go through the steps of ball milling, sieving, iron removal and pool storage, and then make slurry;

[0049] 2) making a mold, using gypsum powder to cast and form a gypsum mold for producing ceramics;

[0050] 3) Forming and pouring, through grouting, grouting and demoulding into the plaster mold, and then trimming and production of semi-finished green bodies;

[0051] 4) The sintered and glazed semi-finished products are products formed after high-temperature firing in the kiln. The firing time is 17 hours to 20 hours, and the firing temperature is 1210 ° C to 1290 ° C;

[0052] 5) Inspection.

[0053] The sintering process is performed twice, the first sintering temperature is 800-1100°C, the duration is 8-10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com