Fully-automatic double-station board turnover device

A fully automatic, double-station technology, applied in the field of turning machines, can solve the problems that the speed of material feeding cannot keep up with the speed of engraving, increase production costs, and strengthen labor intensity, so as to save the machine waiting for manual clamping of materials. time, time saving manual material clamping, time and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

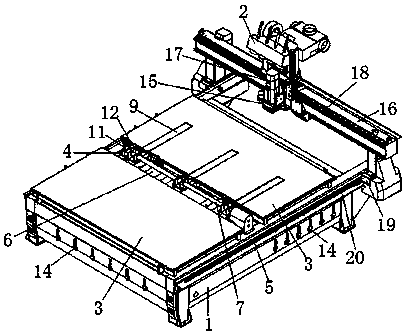

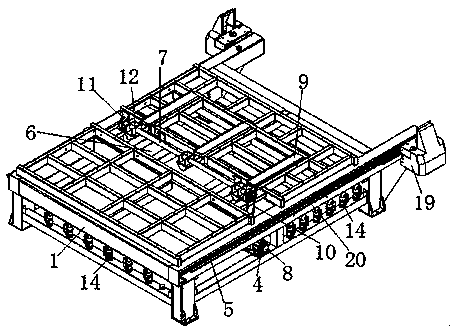

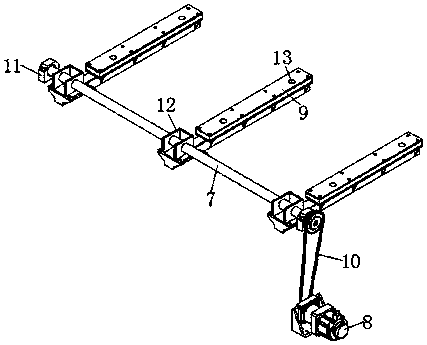

[0042] Such as Figure 4 As shown, when people need to carry out double-sided processing on the wooden board on the flap fixing seat, the main body of the engraving machine completes the front processing of the wooden board under the drive of the sliding device. The turning and absorbing wooden board is sucked and turned over on the wooden board, so that the wooden board is turned from the original station to the station on the other side of the turning device. After the turning is completed, the engraving machine body is driven by the sliding device to complete the reverse processing of the wooden board.

Embodiment 2

[0044] Such as Figure 5 As shown, if the wood board only needs to be processed on one side, the main body of the engraving machine can process the two stations on one side in turn. When one station is processing, the other station can be used to place materials, saving the machine. Waiting time for manual clamping of materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com