Method for preparing biochar-base fertilizer from cotton straws

A cotton straw and biochar technology, applied in fertilizer mixtures, applications, fertilization devices, etc., can solve problems such as pests and diseases, and achieve the effects of slowing down global warming, reducing air pollution, and reducing secondary pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

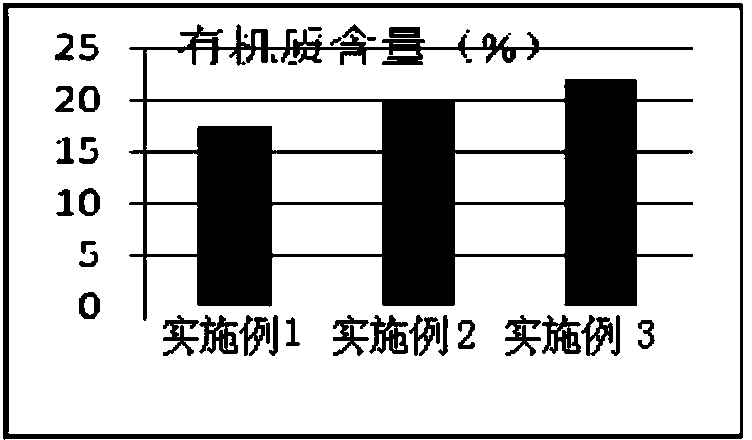

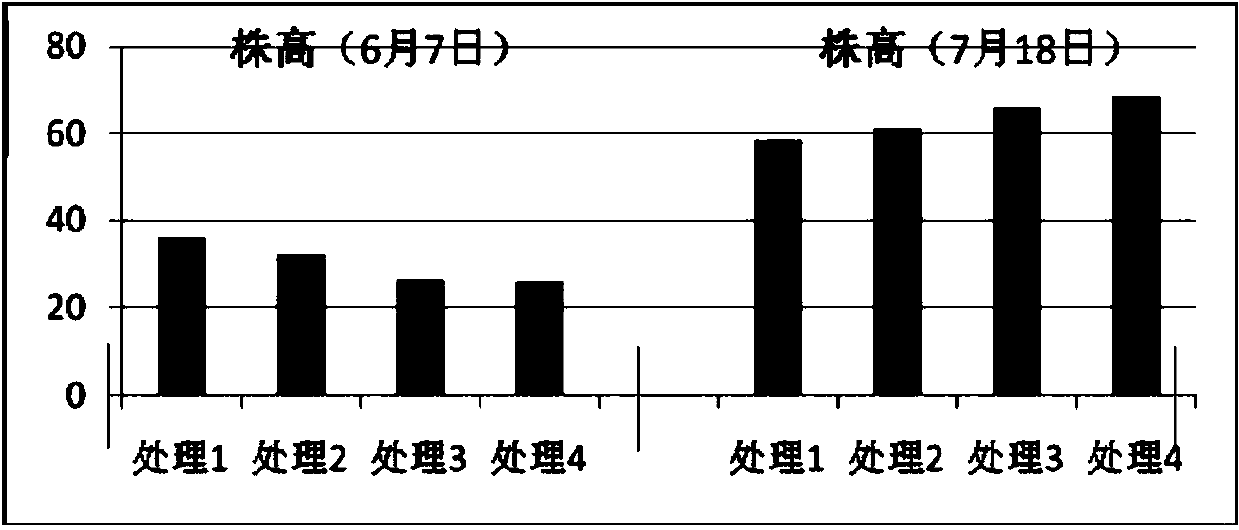

Embodiment 1

[0030] The biochar-based fertilizer of this embodiment is a special biochar-based fertilizer for cotton

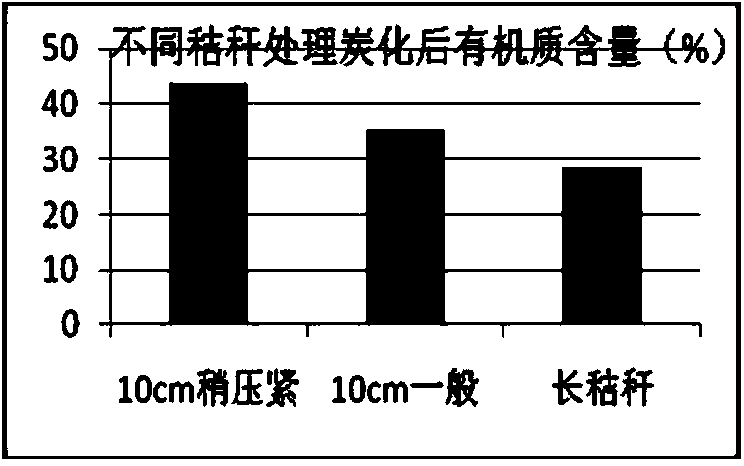

[0031] Crush the gypsum, bentonite and cotton straw biochar, pass the gypsum and bentonite through a 100-mesh sieve, and pass the cotton straw biochar through a 40-mesh sieve.

[0032] The addition amount of every 100 kilograms of cotton-specific biochar-based fertilizer raw materials is as follows: 18.2 kilograms of ammonium phosphate (P 2 o 5 -44, N-11), 8.7 kg of urea, 8 kg of potassium sulfate (K 2 O-50), 1.5 kg of zinc sulfate, 1.5 kg of boric acid, 8.1 kg of nitrohumic acid, 30 kg of cotton straw biochar, 12 kg of gypsum and 12 kg of bentonite were mixed together and stirred evenly to obtain a fertilizer mixture. Heat to make the temperature of the fertilizer mixture at 60°C, and the water content of the fertilizer mixture is 4-10%.

[0033] The fertilizer mixture is firstly granulated with a drum granulator, and then shaped and granulated with a disc granulator t...

Embodiment 2

[0036] The biochar-based fertilizer of this embodiment is a special biochar-based fertilizer for cotton

[0037] Crush the gypsum, bentonite and cotton straw biochar, pass the gypsum and bentonite through a 100-mesh sieve, and pass the cotton straw biochar through a 40-mesh sieve.

[0038] The addition amount of every 100 kilograms of cotton-specific biochar-based fertilizer raw materials is as follows: 18.2 kilograms of ammonium phosphate (P 2 o 5 -44, N-11), 8.7 kilograms of urea, 8.1 kilograms of potassium sulfate (K 2 O-50), 1.5 kg of zinc sulfate, 1.5 kg of boric acid, 8.1 kg of nitrohumic acid, 35 kg of cotton straw biochar, 9.5 kg of gypsum and 9.5 kg of bentonite were mixed together and stirred uniformly to obtain a fertilizer mixture. Heat to make the temperature of the fertilizer mixture at 65°C, and the water content of the fertilizer mixture is 4-10%.

[0039] The fertilizer mixture is firstly granulated with a drum granulator, and then shaped and granulated wit...

Embodiment 3

[0042] The biochar-based fertilizer of this embodiment is a special biochar-based fertilizer for cotton

[0043] Crush the gypsum, bentonite and cotton straw biochar, pass the gypsum and bentonite through a 100-mesh sieve, and pass the cotton straw biochar through a 40-mesh sieve.

[0044] The addition amount of every 100 kilograms of cotton-specific biochar-based fertilizer raw materials is as follows: 18.2 kilograms of ammonium phosphate (P 2 o 5 -44, N-11), 8.7 kg of urea, 8 kg of potassium sulfate (K 2 O-50), 1.5 kg of zinc sulfate, 1.5 kg of boric acid, 8.1 kg of nitrohumic acid, 40 kg of cotton straw biochar, 7 kg of gypsum and 7 kg of bentonite were mixed together and stirred evenly to obtain a fertilizer mixture. Heat to make the temperature of the fertilizer mixture at 70°C, and the water content of the fertilizer mixture is 4-10%.

[0045]The fertilizer mixture is firstly granulated with a drum granulator, and then shaped and granulated with a disc granulator to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com