Method for producing nitrogen-fixing potassium slow-release compound fertilizer with mesh inner membrane by using ammonia-acid method

A compound fertilizer and production method technology, applied in fertilizer mixture, fertilization device, application, etc., can solve the problems of high cost of high-density inert film, uncontrollable film thickness, secondary pollution of soil environment, etc., and achieve low cost and good absorption , good slow-release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

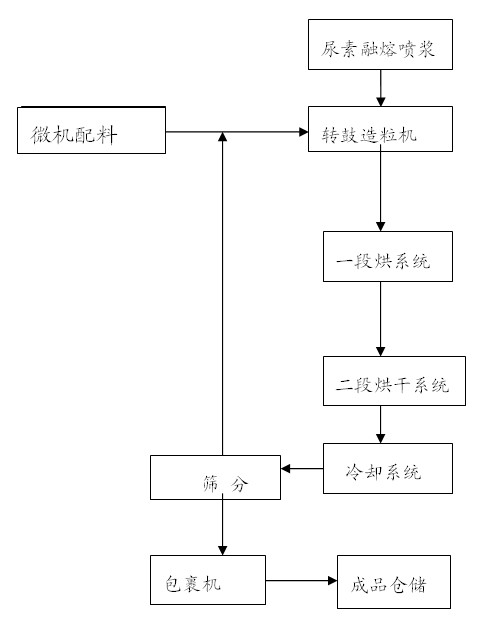

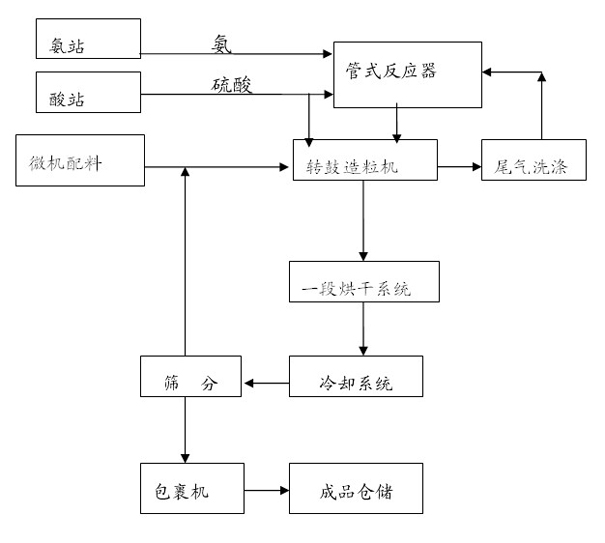

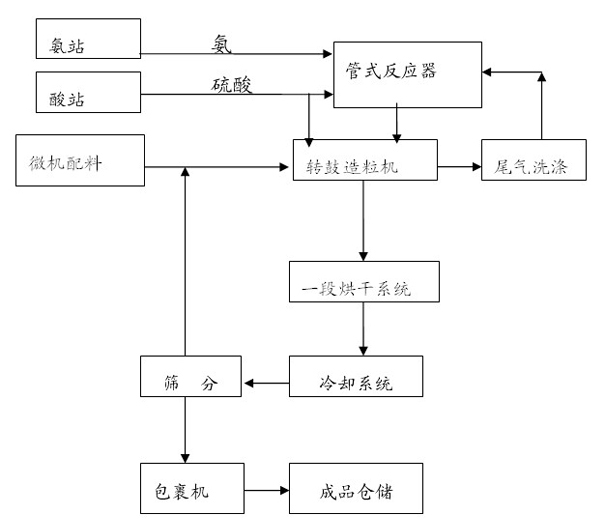

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: 15-15-15 conventional products

[0052] Concentrated sulfuric acid with a concentration of 98% (mass percentage, the same below) is 30 kg, pumped into the tubular reactor after metering, and the washing water is metered and added to the tubular reactor to complete the dilution of the concentrated sulfuric acid. After dilution The mass percent concentration of sulfuric acid is 50%, and 27 kg of gaseous ammonia (containing 82.3% N) is metered and added to the tubular reactor, and the reaction temperature of ammonia and acid is controlled at 180°C. Concentrated sulfuric acid with a concentration of 98% (mass percentage, the same below) is 20 kg, diluted with washing water into dilute sulfuric acid with a concentration of 30% by mass, and pumped into the drum granulator after metering. At the same time, 215 kg of urea (containing 46.2% of N, added after crushing), 255 kg of powdered monoammonium phosphate (containing 11% of N, 45% of P2O5), and 250 kg of potas...

Embodiment 2

[0053] Embodiment 2: 22-12-8 high nitrogen product

[0054] Concentrated sulfuric acid with a concentration of 98% (mass percentage, the same below) is 20 kg, pumped into the tubular reactor after metering, and the washing water is metered and added to the tubular reactor to complete the dilution of the concentrated sulfuric acid. After dilution The mass percent concentration of sulfuric acid is 50%, and 27 kg of gaseous ammonia (containing 82.3% N) is metered and added to the tubular reactor, and the reaction temperature of ammonia and acid is controlled at 180°C. Concentrated sulfuric acid with a concentration of 98% (mass percentage, the same below) is 30 kg, diluted with washing water into dilute sulfuric acid with a concentration of 30% by mass, and pumped into the drum granulator after metering. At the same time, 340 kg of urea (containing 46.2% of N, added after crushing), 68 kg of ammonium chloride (containing 25.2%) of ammonium chloride, and 195 kg of powdered monoamm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com