Spherical porous carbon and preparation method thereof

A porous carbon and spherical technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., to achieve the effect of high ball forming rate, strong continuous operability, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

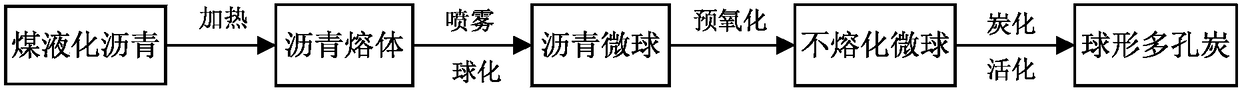

[0034] In order to solve this problem, the invention provides a kind of preparation method of spherical porous carbon, such as figure 1 As shown, the method includes: adding coal liquefied pitch to obtain pitch melt; spray drying the pitch melt to obtain pitch microspheres; pre-oxidizing the pitch microspheres to obtain infusible pitch microspheres; Spherical porous carbon is obtained after infusible pitch microspheres are carbonized and activated.

[0035] The present invention uses coal liquefaction pitch as raw material to prepare spherical porous carbon through heating, spheroidization, pre-oxidation, carbonization, activation and other processes. High carbon content, easy polymerization or cross-linking product characteristics. On the other hand, the present invention adopts a spray drying process in the asphalt spheroidization process, which has simple steps, strong continuous operability, high spheroidization rate, high sphericity and adjustable particle size of micros...

Embodiment 1

[0048] In a 2L stirred tank, at a stirring speed of 100r / min, add 1000g of coal liquefied pitch with a particle size of less than 3mm, an ash content of 0.001%, a softening point of 110°C, and a coking value of 50%, and heat up at a rate of 5°C / min to 160°C, and stirred at a constant temperature for 0.5h to obtain a coal liquefaction bitumen melt.

[0049] Fill the stirred tank with nitrogen, control the pressure to 0.1MPa, open the valve on the pipeline between the bottom of the tank and the centrifugal spray drying tower, control the feed rate to 10kg / h, feed temperature to 160°C, and press all the asphalt melt into a spray drying tower, and 850 g of asphalt microspheres with a sphericity of 90% and a particle size of 0.5 to 1.5 mm were collected from the bottom of the tower.

[0050] Put the asphalt microspheres in a horizontal tubular carbonization furnace, in the air of 100mL / min, raise the temperature to 250 °C at a rate of 0.1 °C / min, pre-oxidize at a constant temperatu...

Embodiment 2

[0053] In a 2L stirred tank, at a stirring speed of 50r / min, add 1200g of coal liquefied pitch with a particle size of less than 3mm, an ash content of 0.01%, a softening point of 132°C, and a coking value of 52.5%, and heat up at a rate of 10°C / min to 192°C, and stirred at constant temperature for 1 hour to obtain a coal liquefaction bitumen melt.

[0054] Fill the stirred tank with nitrogen, control the pressure to 0.5MPa, open the valve on the pipeline between the bottom of the tank and the centrifugal spray drying tower, control the feed rate to 8kg / h, feed temperature to 192°C, press all the bitumen melt Into the spray drying tower, 987 g of pitch microspheres with a sphericity of about 93.5% and a particle size of 0.1 to 1.1 mm were collected from the bottom of the tower.

[0055] Put the asphalt microspheres in a horizontal tubular carbonization furnace, in the air of 150mL / min, raise the temperature to 270°C at a rate of 0.5°C / min, pre-oxidize at a constant temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com