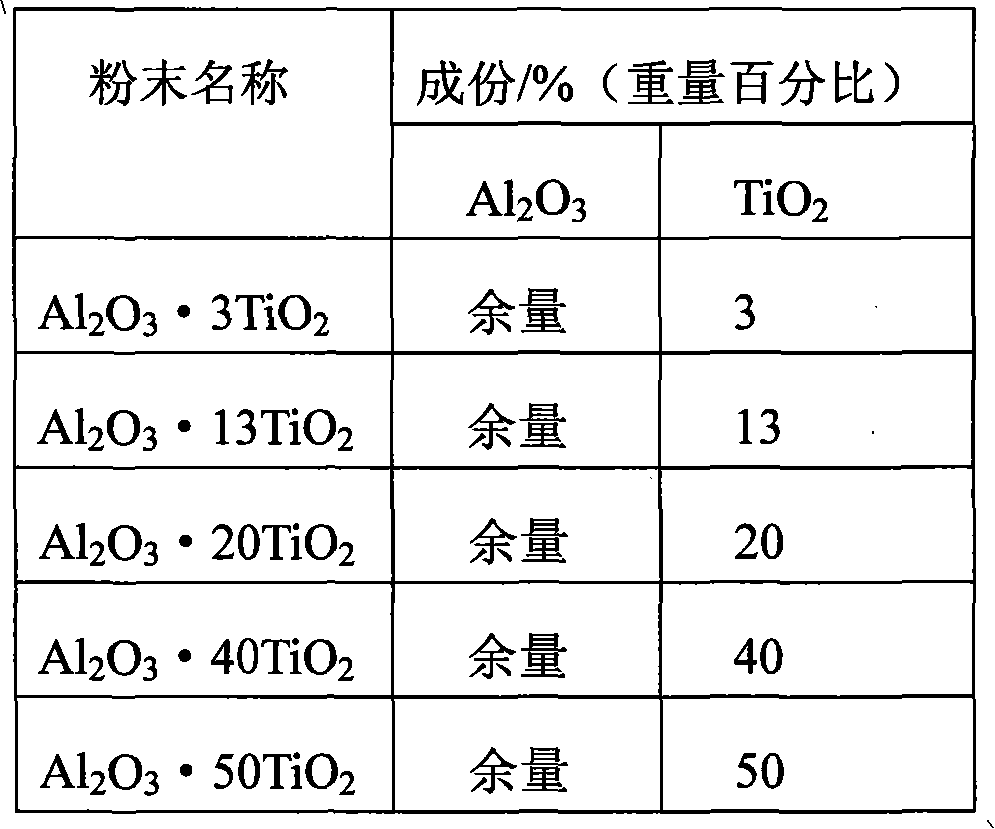

Preparation method of aluminium oxide and titanium dioxide compound ceramic powder

A composite ceramic and titanium oxide technology, applied in the field of preparation of alumina-titanium oxide composite ceramic powder, can solve the problems of large one-time investment, expensive process equipment, poor fluidity, etc., and achieves high bulk density, good repeatability, Good abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

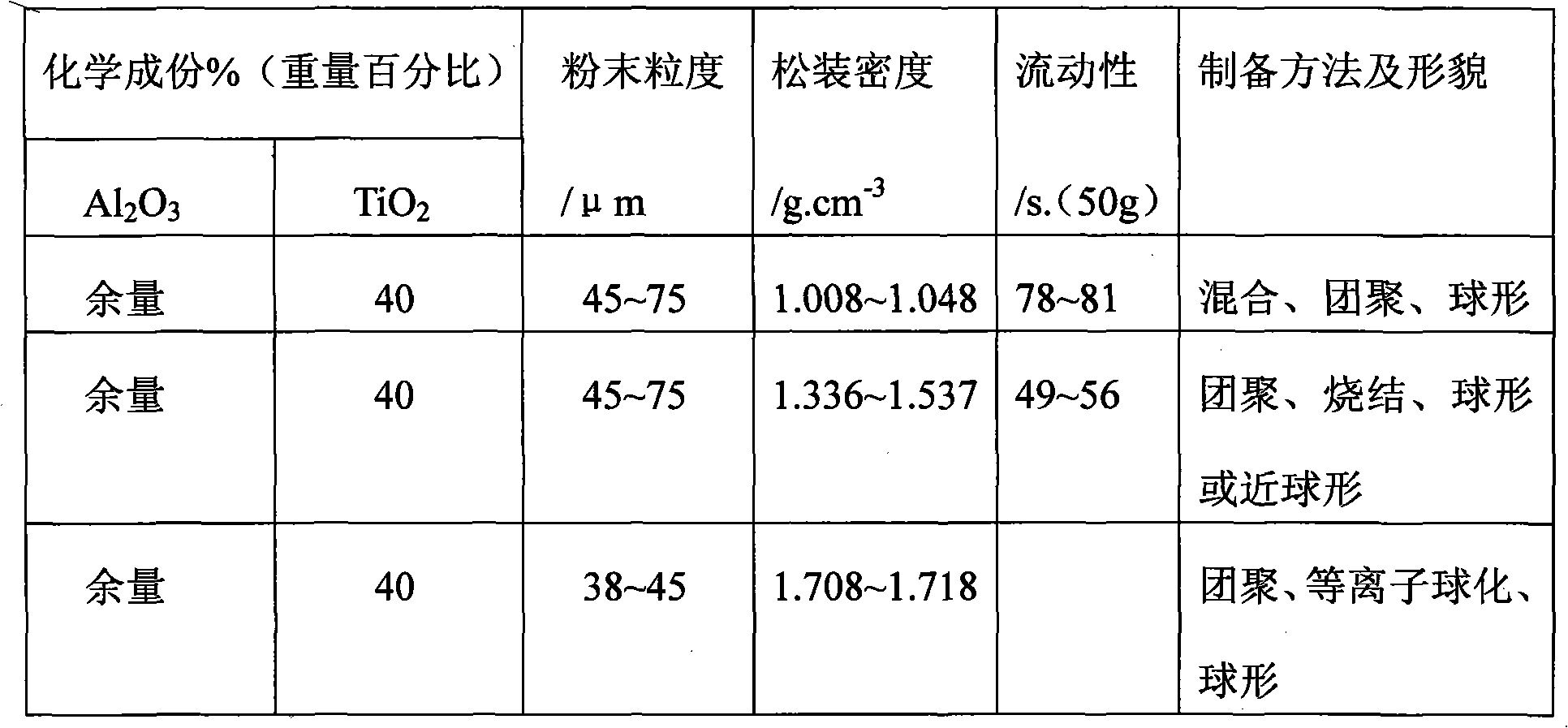

[0093] Will Al 2 o 3 ·TiO 2 The powder is batched and mixed according to the weight ratio, and the water consumption is: material: water = 1: 2.5;

[0094] Binder dosage: material: binder = 100: 0.8; defoamer dosage: material: defoamer = 100: 0.4, dispersant dosage: material: dispersant = 100: 0.4;

[0095] Lubricant dosage: material: lubricant = 100:0.3, make slurry, then spray dry, process parameters: inlet air temperature: 290°C; exhaust air temperature: 95°C; atomizing disk speed: 1420 (r.p.m); peristaltic pump The rotation speed is 52 (r.p.m); the spray-dried granular powder is prepared, and the mixed and agglomerated powder is obtained through sieving and classification. The spray-dried granulated powder is sintered at 1300°C or plasma spheroidized, rinsed, and sedimented for classification to obtain agglomerated, sintered and agglomerated, plasma spheroidized powders.

Embodiment 2

[0097] The preparation method and procedure are the same as in Example 1, except that the amount of binder is changed, ie material: binder=100:1.0.

Embodiment 3

[0099] The preparation method and procedure are the same as in Example 1, except that the amount of antifoaming agent is changed, that is, material: antifoaming agent=100:0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com