Method for preparing titanium concentrate pellet

A technology of titanium concentrate and pellets, applied in the field of titanium concentrate manufacturing pellets and titanium slag electric furnace dust removal, can solve the problems of waste of resources, low grade dust removal, fine particle size, etc., to achieve resource saving, good economic benefits, The effect of high ball formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

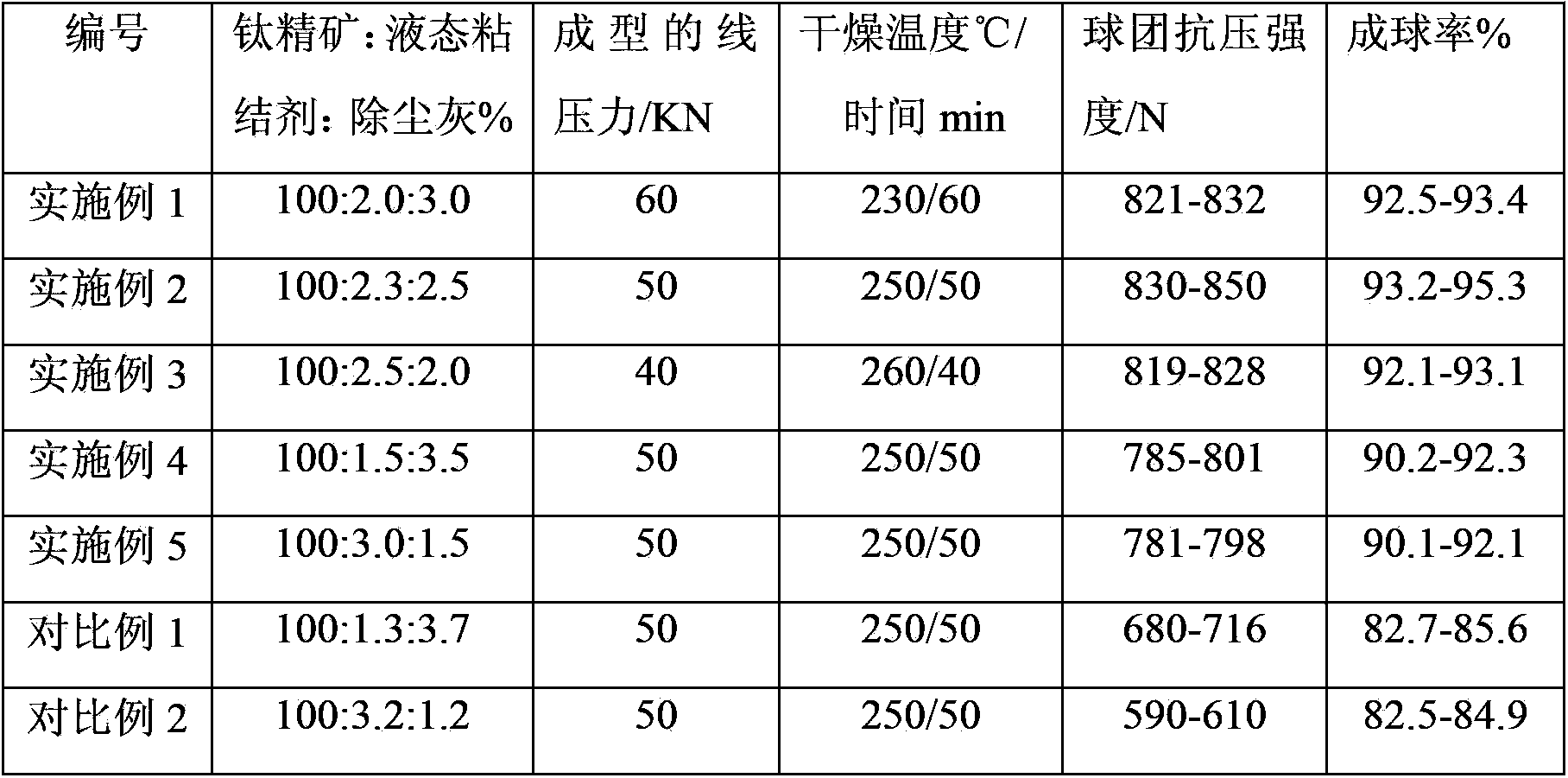

Examples

preparation example Construction

[0008] The present invention provides a method for preparing titanium concentrate pellets. The method includes: mixing titanium concentrate, liquid binder, and dust removal ash and pelletizing, wherein the dust removal ash is a titanium smelting slag in the process Dust removal ash produced in titanium slag electric furnace.

[0009] In the process of smelting titanium slag, the feeding process is carried out from the feeding hole on the furnace cover of the electric furnace. The furnace cover is 4-5m high from the lower molten pool, and the furnace cover is equipped with a dust removal system exhausting fume hood. There are usually many fine powders in the raw materials of titanium slag electric furnaces. When feeding, the fine powders are difficult to fall and float over the molten pool in the furnace. The fine powders are pumped away with the flue gas generated by the reaction in the furnace, and then enter the dust removal system. Collected, it is the dust removal ash describ...

Embodiment 1

[0028] This example is used to illustrate the preparation method of titanium concentrate pellets provided by the present invention.

[0029] Raw materials: titanium concentrate, particle size of 0.074mm; liquid binder, containing 23% by weight starch gum, 2% by weight sodium carboxymethyl cellulose and 75% by weight of industrial water; dust removal ash, particle size of 0.063mm. The weight ratio is, titanium concentrate: liquid binder: dust removal ash = 100: 2.0: 3.0.

[0030] First put the titanium concentrate and dust removal ash into the mixer according to the ratio of 100:3.0, mix in the dry powder state for 5 minutes, and then add the liquid to the mixer according to the weight ratio of titanium concentrate: liquid binder = 100: 2.0 The binder is mixed for a total mixing time of 30 minutes, and then the three mixtures are added to the ball press using a 60KN linear pressure to be extruded to a size of 20×25×18mm, and then added to the dryer to dry at 230°C for 60 minutes. F...

Embodiment 2

[0032] This example is used to illustrate the preparation method of titanium concentrate pellets provided by the present invention.

[0033] Raw material: titanium concentrate, particle size of 0.08mm; liquid binder, containing 24% by weight starch gum, 3% by weight sodium carboxymethyl cellulose and 73% by weight of industrial water; dust removal ash, particle size of 0.075mm. The weight ratio is titanium concentrate: liquid binder: dust removal ash=100:2.3:2.5.

[0034] First add titanium concentrate and dust removal ash into the mixer at a ratio of 100:2.5, mix for 10 minutes in a dry powder state, and then add liquid to the mixer according to the weight ratio of titanium concentrate: liquid binder = 100: 2.3 The binder is mixed for a total mixing time of 35 minutes, and then the three mixtures are added to the ball press using a line pressure of 50KN to be extruded to a size of 20×25×18mm, and then added to the dryer to dry at 250°C for 50 minutes. Finally, the titanium concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com