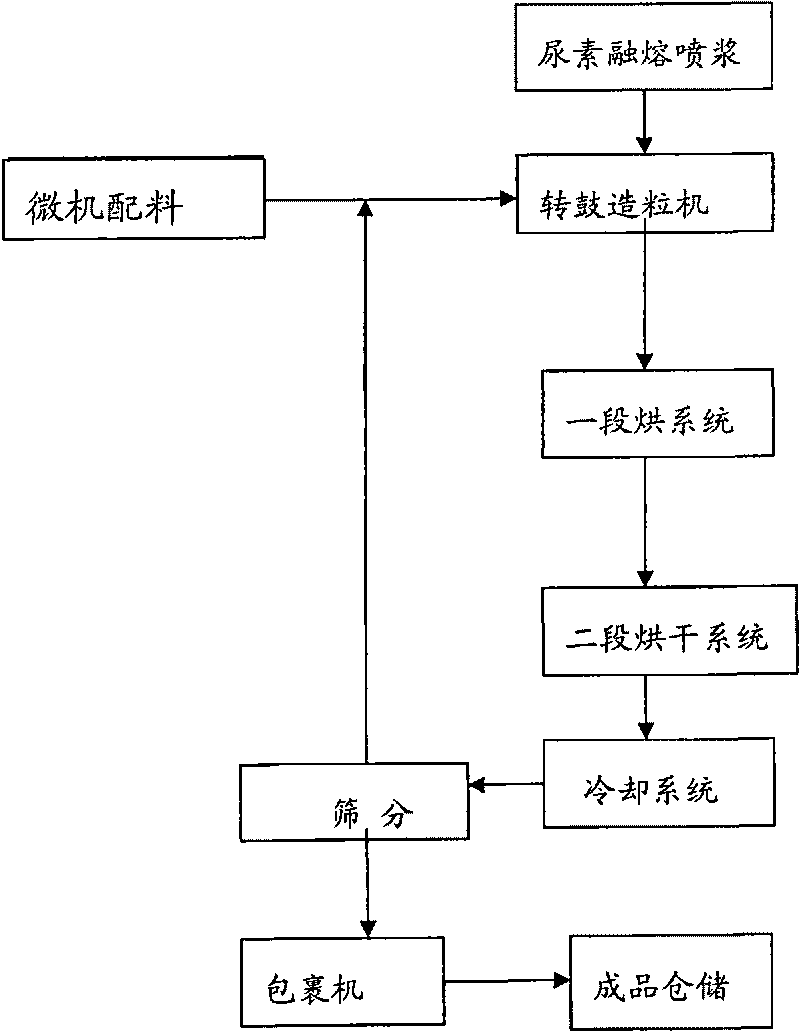

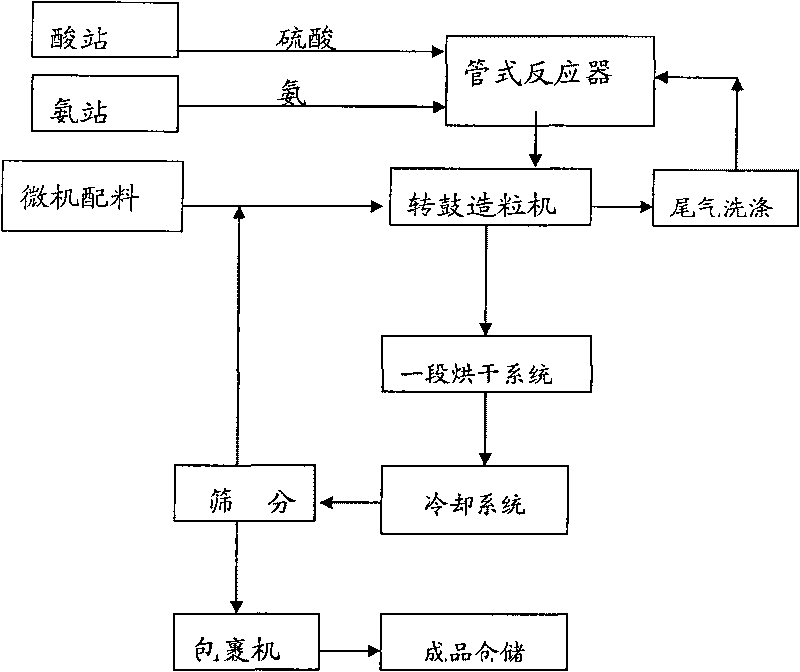

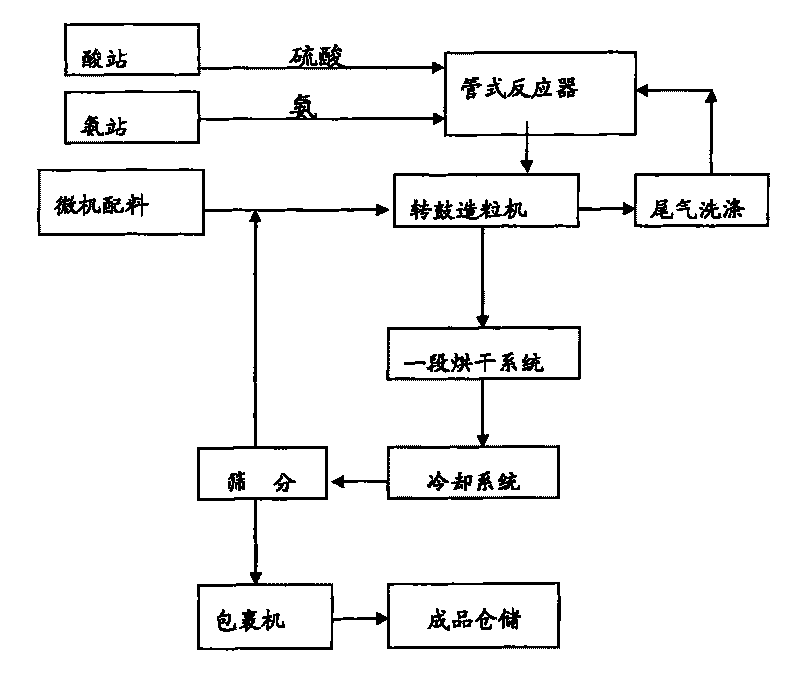

Method for producing Nitrogen-Phosphorus-Potassium compound fertilizer by ammonia and acid tubular reactor

A tubular reactor, ternary compound fertilizer technology, applied in the application, fertilizer form, fertilization device and other directions, can solve the problems of rough product appearance, high product cost, low ball forming rate, etc., to save equipment investment and a large amount of energy. The effect of high consumption, strong adaptability of raw materials and high ball forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: 15-15-15 conventional products

[0048] Concentration is 50 kilograms of concentrated sulfuric acid (mass percentage, the same below) of 98%, pumps into tubular reactor after metering, and washing water joins tubular reactor after metering and finishes the dilution to concentrated sulfuric acid, after dilution The mass percentage concentration of sulfuric acid is 50%, and 30 kilograms of gaseous ammonia (containing N82.3%) is added into tubular reactor after metering, and ammonia, acid reaction temperature are controlled at 180 ℃. At the same time, 358 kilograms of ammonium chloride (containing N23.5) and powdered monoammonium phosphate (containing N11%, P 2 o 5 45%) 340 kg, potassium chloride (containing K 2 O 60%) 255 kilograms, the ammonium sulfate solution that above-mentioned powdery material and tubular reactor spray mixes in granulator, and the material temperature in drum granulator is controlled at 60 ℃, after 3min granulation, enters drying Machi...

Embodiment 2

[0049] Embodiment 2: 25-10-5 high nitrogen product

[0050] Concentration is 35 kilograms of concentrated sulfuric acid (percentage by weight, hereinafter the same) of 98%, pumps into tubular reactor after metering, 30 kilograms of gaseous ammonia (containing N 82.3%), joins tubular reactor after metering, After the washing water is metered, it is added to the tubular reactor and the dilution of the concentrated sulfuric acid is completed. The mass percentage concentration of the diluted sulfuric acid is 60%, and the reaction temperature of ammonia and acid is controlled at 200°C. At the same time, 400 kilograms of ammonium chloride (containing N23.5), 235 kilograms of crushed urea (containing N46.2), powdered monoammonium phosphate (containing N11%, P 2 o 5 45%) 225 kg, potassium chloride (containing K 2 (060%) 85 kilograms, the ammonium sulfate solution that above-mentioned powdery material and tubular reactor spray mixes in the granulator, and the material temperature in ...

Embodiment 3

[0051] Example 3: 13-23-12 high phosphorus product

[0052] 40 kg of concentrated sulfuric acid (weight percentage, the same below) with a concentration of 98% is pumped into the tubular reactor after metering, and 30 kg of gaseous ammonia (containing N82.3%) is added into the tubular reactor after metering After metering, the washing water is added to the tubular reactor and the dilution of concentrated sulfuric acid is completed. The concentration of sulfuric acid after dilution is 70% by mass, and the reaction temperature of ammonia and acid is controlled at 220°C. At the same time, 185 kilograms of ammonium chloride (containing N22.8), 20 kilograms of urea (containing N46.2), powdered monoammonium phosphate (containing N11%, P 2 o 5 45%) 510 kg, potassium chloride (containing K 2 (055%) 220 kg, the above-mentioned powdery material and the ammonium sulfate solution sprayed from the tubular reactor are mixed in the granulator, and the temperature of the material in the dru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com