Method for producing semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as reducing the controllability of aluminum diffusion to semiconductor substrates, and achieve the effect of improving controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

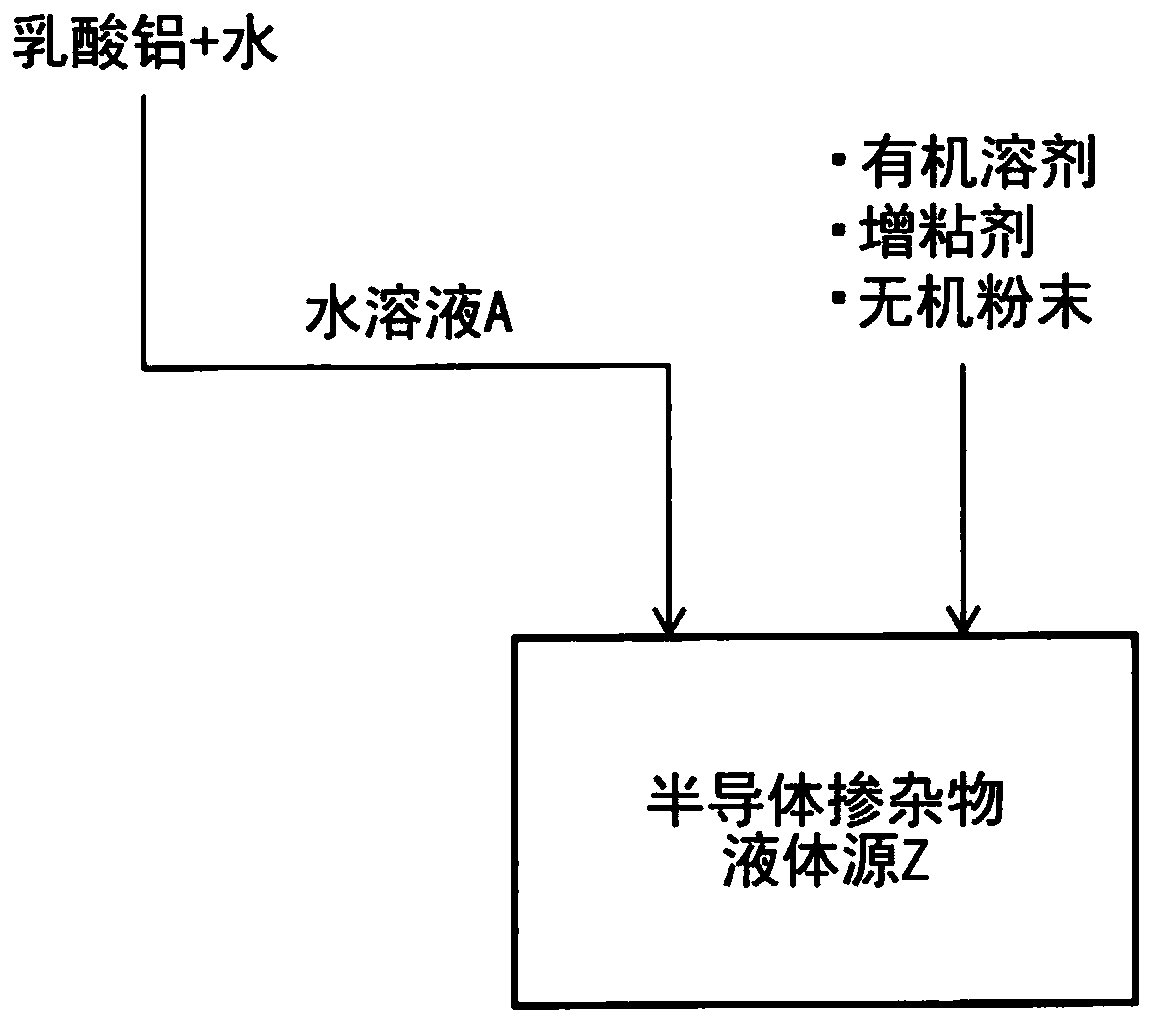

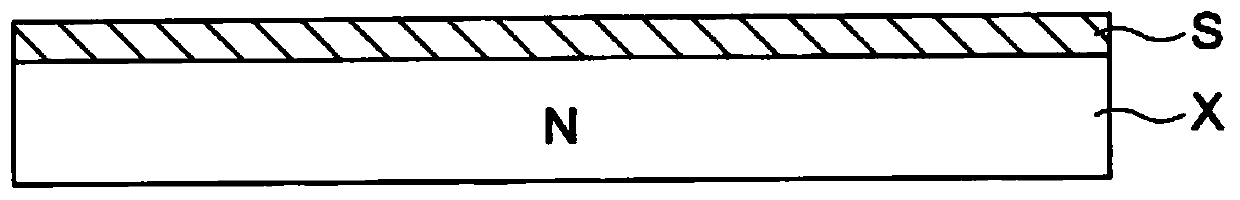

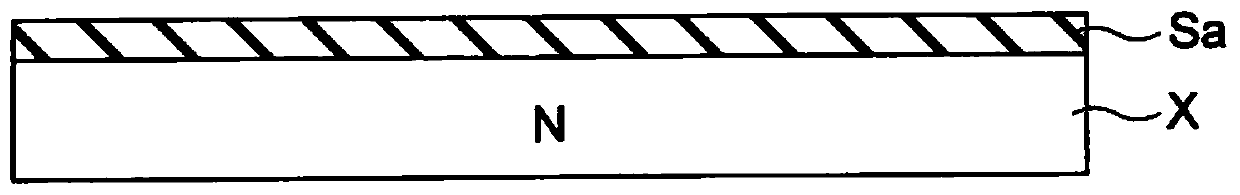

[0075] figure 1 It is a diagram showing a configuration example of a semiconductor dopant liquid source in the method for manufacturing a semiconductor device of the present invention. Figure 2 to Figure 5 It is a process illustration diagram of the manufacturing method of the semiconductor device concerning Example 1.

[0076] The manufacturing method of the semiconductor device related to the first embodiment is as follows Figure 2 to Figure 5 As shown, the "dissolving step", "mixing step", "coating step", "firing step", "diffusion step", and "peeling step" were sequentially carried out. Next, the method of manufacturing the semiconductor device according to the first embodiment will be described in the order of the above-mentioned steps.

[0077] Dissolving process

[0078] First, aluminum lactate was dissolved in water to make aqueous solution A ( figure 1 ).

[0079] Here, as the liquid source of the P-type semiconductor dopant for diffusing the P-type dopant on ...

Embodiment 2

[0121] In one of the above-mentioned embodiments, a mode in which aluminum as a P-type dopant is diffused on one semiconductor substrate has been described. However, as described above, aluminum as a P-type dopant can be diffused on a plurality of (two or more) semiconductor substrates by laminating semiconductor substrates.

[0122] In the second embodiment, a mode in which a desired dopant is diffused on a plurality of semiconductor substrates by stacking semiconductor substrates will be described in detail. In the second embodiment, the diffusion process in the first embodiment is described as a deposition process and a diffusion process.

[0123] (Semiconductor dopant liquid source)

[0124] First, the semiconductor dopant liquid source related to the second embodiment will be described.

[0125] The semiconductor dopant liquid source according to the second embodiment is heated while being applied between a plurality of stacked semiconductor substrates, so that dopants ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com