Mullite flame-proof spray paint

A technology of mullite and spray paint, which is applied in the field of spray paint, can solve the problems of lack of fire-resistant spray paint, achieve high early strength, improve technical parameters, and increase flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Based on the damage mechanism of refractory materials in various parts of the new dry-process cement rotary kiln system, and according to the practical experience of our company, when designing a new mullite refractory spray coating for the spraying method, our basic principle is that the selected raw materials need Low body density, easy collection of raw materials, relatively uniform particles, low rebound rate, and relatively fast drying speed. Under the guidance of this idea, after continuous research and experimentation, the researchers found that the following ratio should be followed in the production process:

[0036] Mullite 80%,

[0037] Pure calcium aluminate cement 7%,

[0038] Silica fume 3%,

[0039] Aluminum Lactate 3%,

[0040] Water 7%.

[0041] The mullite is low aluminum mullite with an aluminum content of 40-60%. The aluminum content of mullite in such an aluminum-containing range is easier to cooperate with other additives to make the aluminum ...

Embodiment 2

[0044] Normally, as a manufacturer, the ratio we adopt is:

[0045] Mullite 75%,

[0046] Pure calcium aluminate cement 7%,

[0047] Silica fume 8%,

[0048] Aluminum Lactate 6%,

[0049] Water 9%.

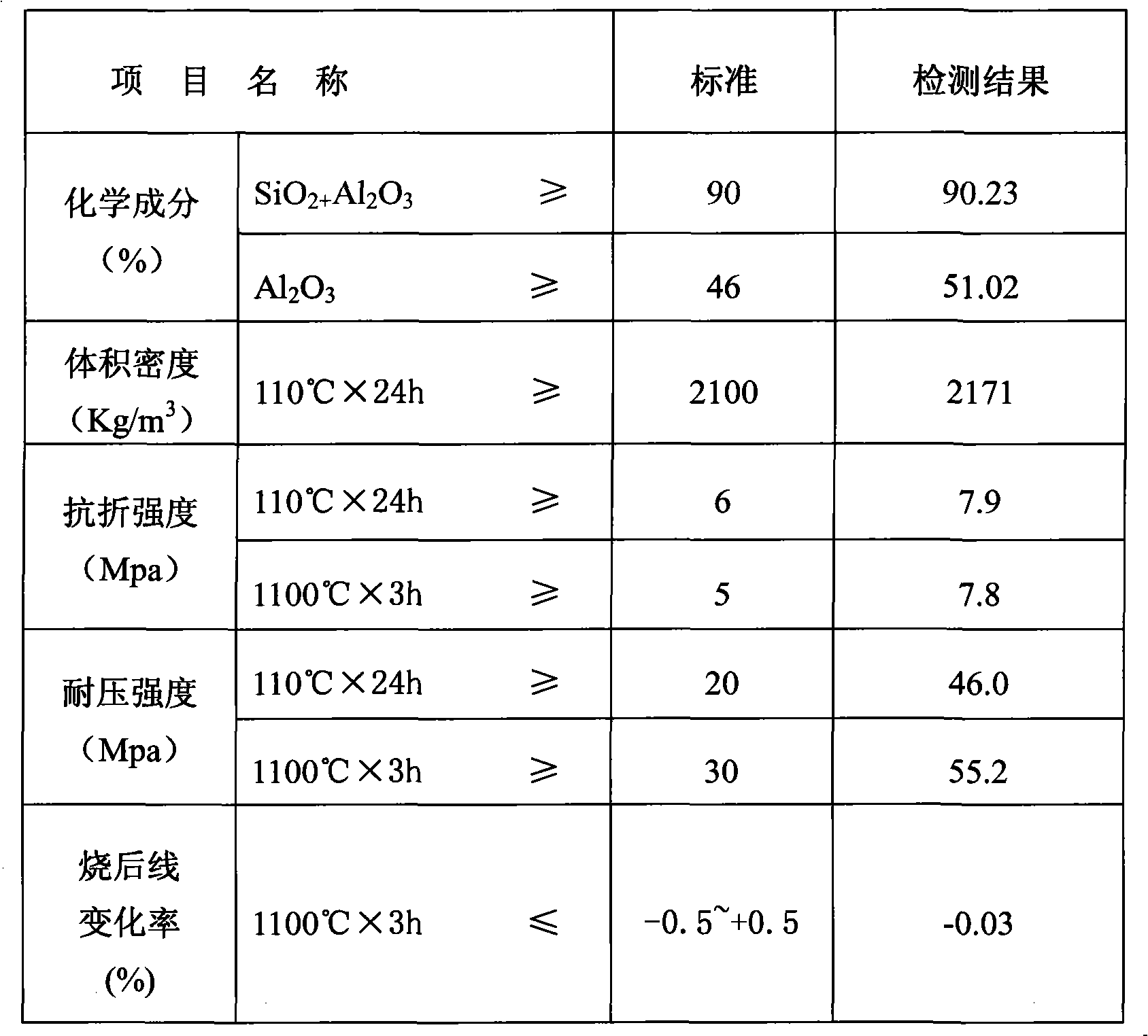

[0050] The mullite is low aluminum mullite with an aluminum content of 45%. Under such proportioning conditions, the performance parameters of the obtained mullite refractory spray coating are:

[0051]

[0052] Such performance conditions can effectively reduce the kiln shutdown time. And ensure the smooth progress of spraying construction.

Embodiment 3

[0054] For some small and medium-sized enterprises, hoping to reduce costs, you can use the following formula.

[0055] Mullite 70%,

[0056] Pure calcium aluminate cement 10%,

[0057] Silica fume 10%,

[0058] Aluminum Lactate 5%,

[0059] Water 5%.

[0060] The mullite is low aluminum mullite with an aluminum content of 40%.

[0061] Under such a ratio, the basic standard requirements can also be met under the premise of slightly sacrificing part of the performance. At the same time, it can save a lot of cost.

[0062] The invention can greatly improve the construction efficiency when used in the spraying process, and can reduce the construction manpower. Due to the traditional pouring process, at least 15 people must work at the same time in a set of processes including material preparation, material transportation, and pouring. And using the spraying process, it can be reduced to 8 people. At the same time, the weight of the product is reduced, making the transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com