Mesoporous aluminum phosphate glass with large specific surface area and preparation method thereof

A technology of mesoporous aluminum phosphate glass and high specific surface area, which is applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc. It can solve the problem of poor optical performance of aluminum phosphate, which is difficult to meet the application of high-temperature catalysts and catalyst carriers, and difficult to meet the optoelectronic field. Use and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

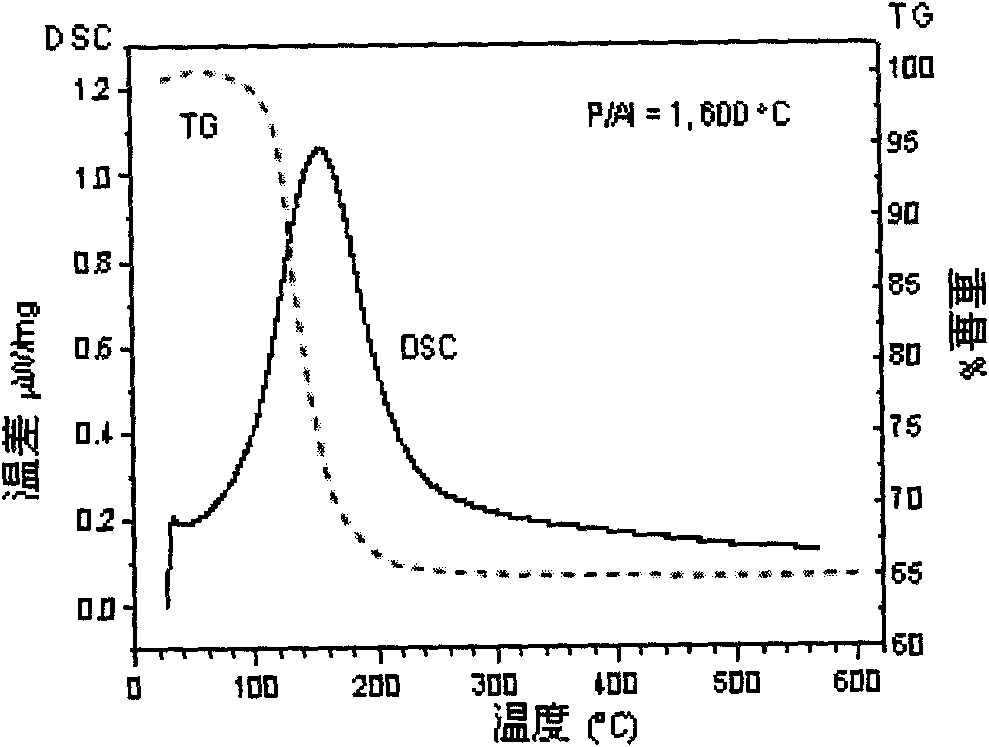

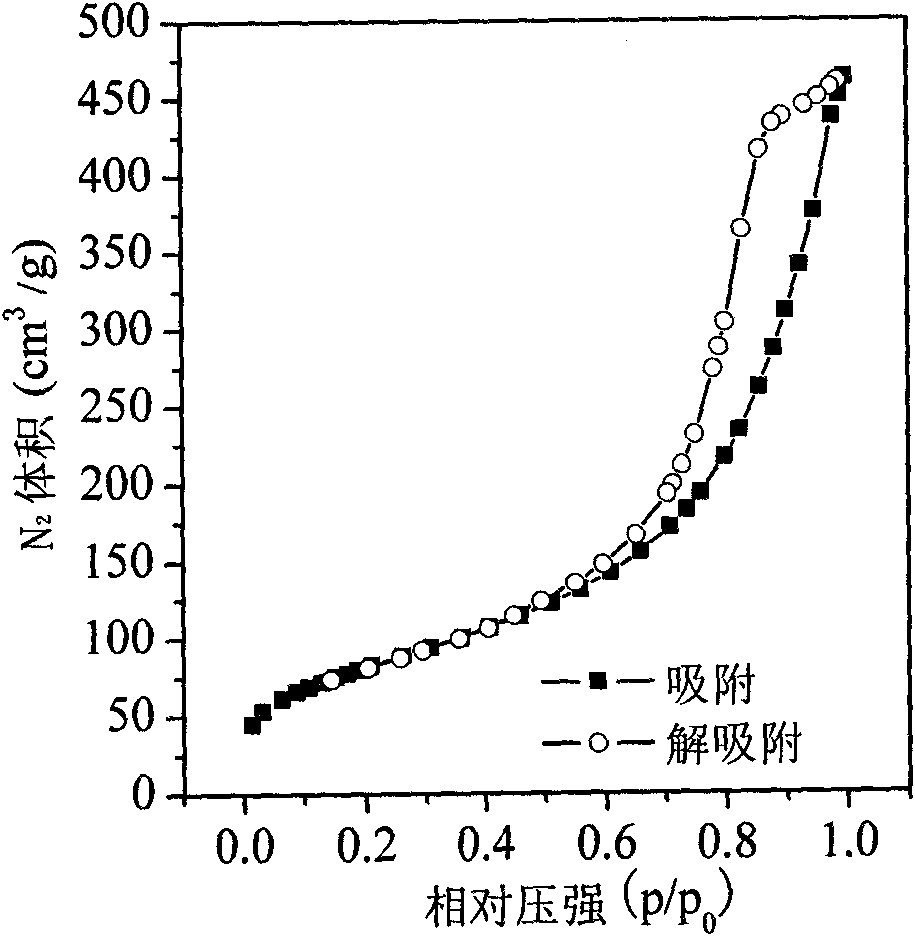

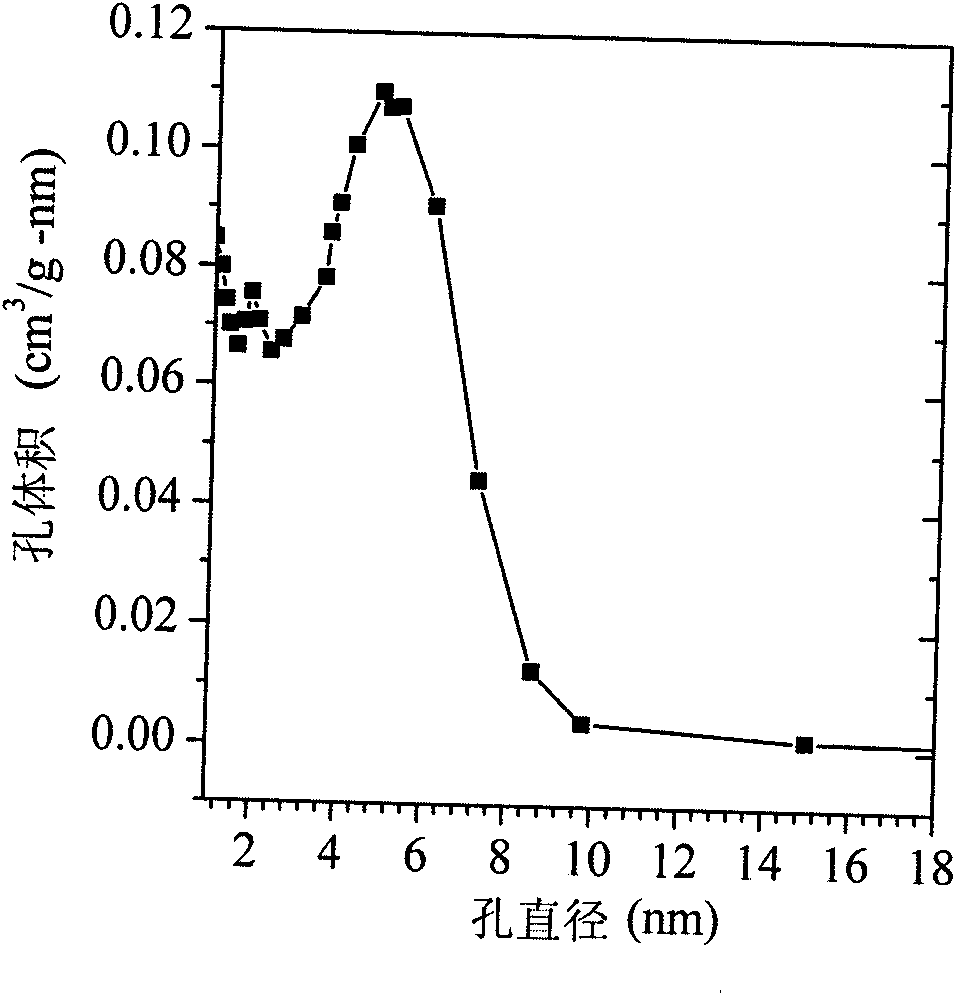

[0023] According to the technical scheme of the present invention, 0.004 mol of aluminum lactate is added into 16 ml of deionized water respectively, and 0.004 mol of orthophosphoric acid solution is added under stirring with a magnetic stirrer. Adjust the pH to 2.40 with 0.50 mol / L dilute ammonia water, and then stir for 2 hours with a magnetic stirrer. The stirred solution was transferred to a watch glass, allowed to stand at room temperature for 1 day, and then transferred to a 50°C oven to dry for 2 weeks. Put the dried sample into a muffle furnace for heat treatment in a corundum crucible, raise the temperature from room temperature to 600°C at a heating rate of 0.5°C / min, and keep it at 600°C for 6 hours to obtain a colorless and transparent mesoporous aluminophosphate glass . Analyze its specific surface area with Brunauer-Emmett-Teller (hereinafter all referred to as BET) specific surface area measuring instrument is 464m 2 / g, the average pore diameter of mesopores ...

Embodiment 2

[0027] According to the technical scheme of the present invention, 0.004 mol of aluminum lactate is added into 24 ml of deionized water respectively, and 0.004 mol of orthophosphoric acid solution is added under stirring with a magnetic stirrer. Then use 1.0 mol / L dilute ammonia water to adjust the pH=2.8, and then use a magnetic stirrer to stir for 4 hours. The stirred solution was transferred to a watch glass, allowed to stand at room temperature for 2 days, and then transferred to a 70 °C oven for 4 days to dry. Put the dried sample into a muffle furnace for heat treatment in a corundum crucible, raise the temperature from room temperature to 650°C at a heating rate of 1°C / min, and keep it at 650°C for 8 hours to obtain a colorless and transparent mesoporous aluminophosphate glass . Analyze its specific surface area with BET specific surface area measuring instrument to be 426m 2 / g, the average pore diameter of mesopores is 3.62nm.

Embodiment 3

[0029] According to the technical scheme of the present invention, 0.004 mol of aluminum lactate is added into 32 ml of deionized water respectively, and 0.004 mol of orthophosphoric acid solution is added under stirring with a magnetic stirrer. Then use 1.5 mol / L dilute ammonia water to adjust the pH=3.0, and then use a magnetic stirrer to stir for 8 hours. The stirred solution was transferred to a watch glass, allowed to stand at room temperature for 4 days, and then transferred to an 85°C oven to dry for 1 week. Put the dried sample into a muffle furnace for heat treatment in a corundum crucible, raise the temperature from room temperature to 700°C at a heating rate of 1.5°C / min, and keep it at 700°C for 10 hours to obtain a colorless and transparent mesoporous aluminophosphate glass . Analyze its specific surface area with BET specific surface area measuring instrument to be 406m 2 / g, the average pore diameter of mesopores is 5.24nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com