Method of making metal 8-quinolinolato complexes

a technology of metal 8quinolinolato and complexes, which is applied in the field of making metal 8quinolinolato complexes, can solve the problems of difficult large-scale purification, significant barrier to large-scale manufacturing, and insufficient purity of products for oled fabrication, etc., and achieves high potential demand, high purity synthesis, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

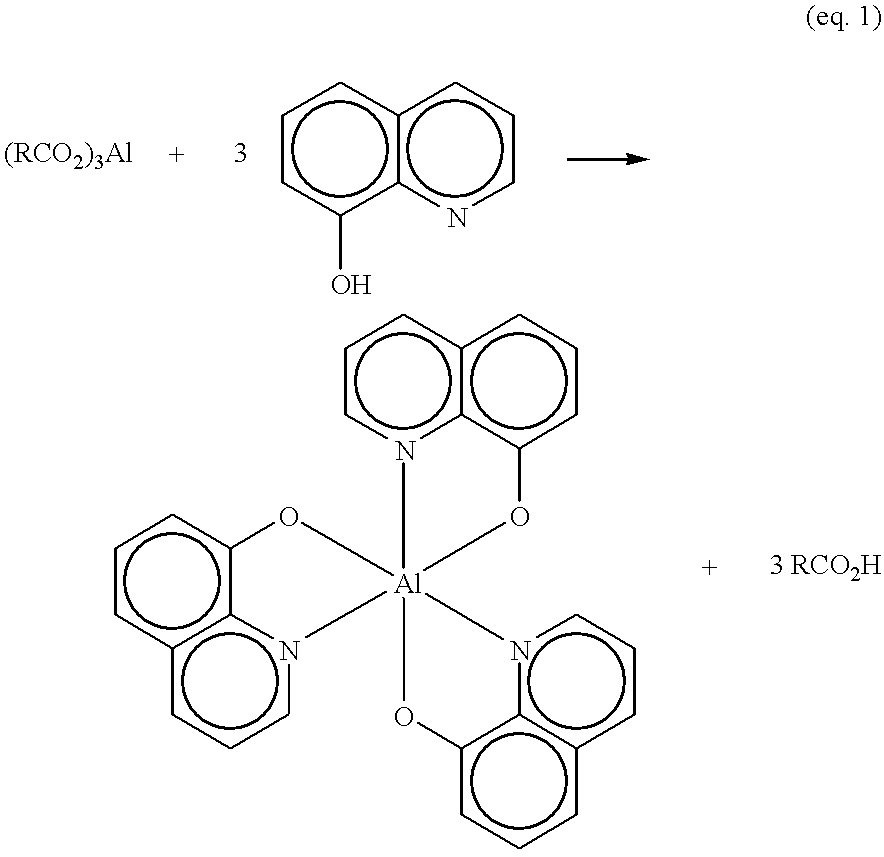

Preparation of AlQ from aluminum lactate and 8-hydroxyquinoline in ethanol.

[0041] Aluminum lactate, Al[CH.sub.3CH(OH)CO.sub.2].sub.3, (10.0 g) and 8-hydroxyquinoline (16.0 g) were placed in a 250 mL round bottomed flask equipped with a magnetic stir bar and a reflux condenser. Ethanol (150 mL, denatured) was added and the cream colored slurry was stirred magnetically. The flask was heated to reflux by means of an electric heating mantle and reflux was maintained for 17 hours. Upon initial heating, the cream colored slurry gradually became yellowish in color. The yellow color intensified as the reaction progressed and the reaction mixture remained heterogeneous throughout the reflux period. After cooling, the reaction mixture was filtered and the yellow filter cake was sequentially washed with two 50 mL portions of ethanol, two 50 ml portions of distilled water, two 50 mL portions of ethanol, and two 50 mL portions of diethyl ether. The filter cake was air dried for 24 hours to give ...

example 2

Preparation of AlQ from aluminum stearate and 8-hydroxyguinoline in toluene.

[0042] Aluminum stearate, Al[CH.sub.3(CH.sub.2).sub.16CO.sub.2].sub.3, (10.0 g, Fisher Scientific Co., Pittsburgh, Pa., technical grade) was placed in a 250 mL round bottomed flask equipped with a magnetic stir bar and a reflux condenser. Toluene (50 mL) was added to give a white slurry. Separately, a 6.0 g sample of 8-hydroxyquinoline (41.3 mmol) was dissolved in 150 mL of toluene and the solution was gravity filtered through a coarse glass frit into the reaction flask. This removed an insoluble minor impurity found in the 8-hydroxyquinoline. After the addition of the 8-hydroxyquinoline to the aluminum stearate-toluene solution, the reaction flask was heated to reflux by means of an electric beating mantle. As the reaction warmed, but prior to refluxing, a large quantity of a fine yellow solid precipitated. The reaction mixture was refluxed for approximately 72 hours, cooled, and filtered. The yellow filter...

example 3

Fabrication and characterization of electroluminescent films using AlQ of the invention.

[0043] Glass substrates with indium-tin oxide (ITO) coatings were purchased from Thin Film Devices, Inc., Anaheim, Calif. Typical ITO sheet resistance was 10-100 ohm / sq. The ITO / glass was rinsed with methanol and dried with N.sub.2. It was then placed in a spinner, covered with xylene, and spun dry. Polyaniline (PANI) (experimental, externally doped material obtained from Monsanto Co., St. Louis, Mo.) dissolved in xylene (typically, 5% solids by weight) was applied through a 0.2 .mu.m filter to cover the substrate. The substrate was spun at 5000 rpm for 20 seconds, providing a polyaniline film of about 1500 .ANG. thickness. The substrate was then immediately moved to an evaporator vacuum chamber and the chamber was evacuated to roughly 10.sup.-6 torr. The evaporator included sources for CuPc, AlQ, TPD, LiF, Al and Sn. All sources were resistively heated tungsten boats. The standard OEL constructi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

| external quantum efficiency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com