Nanometer grade liposome aluminium lactates addictive for daily used chemical product

A nano-liposome and aluminum lactate technology, applied in cosmetics, cosmetics, skin care preparations, etc., to achieve high penetration, high activity, and good anti-dentin hypersensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

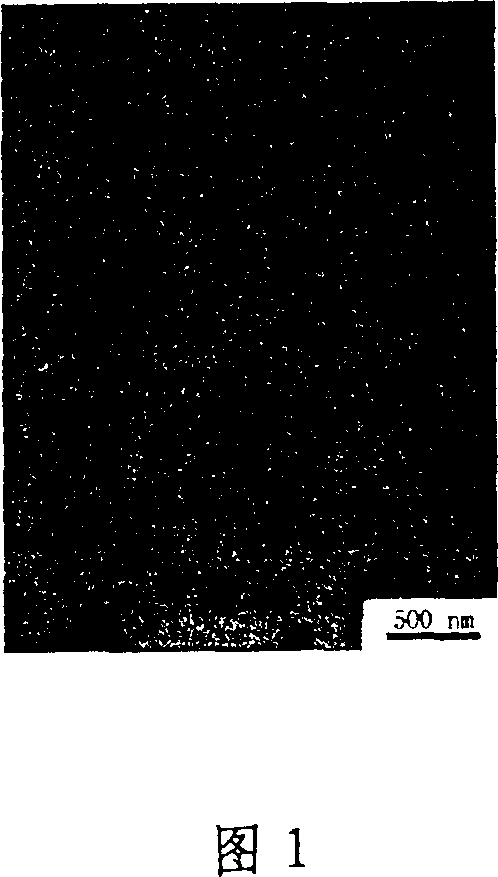

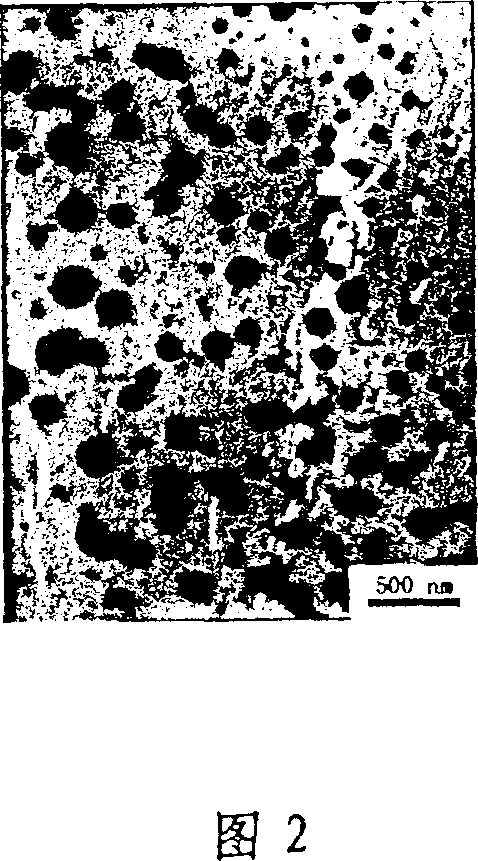

Image

Examples

Embodiment 1

[0026] Accurately weigh 50mg of lecithin, 50mg of cholesterol, and 25mg of vitamin E into a 50mL round bottom flask, add 20mL of a mixed solvent of anhydrous methanol and chloroform with a volume ratio of 1, and shake to dissolve. At 30°C, the mixed solvent was evaporated on a rotary evaporator at a rate of 75 r / min under reduced pressure until a uniform film was formed on the inner wall of the round bottom flask. Add 18mL dissolved in 20mg Pluronic F 68 (Pluronic F 68 ) and 40mg of aluminum lactate aqueous solution, under the condition of 1000r / min, magnetically stirred for 4h. Then, at room temperature, sonicate in an ultrasonic generator for 10 minutes to obtain a mixed solution of nanoliposomes wrapped with aluminum lactate. Place the mixed solution in a dialysis bag with a cut-off molecular weight of 8,000-12,000, and dialyze in PBS buffer solution (pH=7.4) at 4°C for 24 hours to remove unencapsulated aluminum lactate to obtain aluminum lactate-encapsulated nanolipid p...

Embodiment 2

[0028] Accurately weigh 100mg of lecithin, 80mg of cholesterol, and 40mg of vitamin E into a 50mL round bottom flask, add 20mL of anhydrous methanol and chloroform with a volume ratio of 0.5, and shake to dissolve. At 40°C, the mixed solvent was evaporated on a rotary evaporator at a rate of 65 r / min under reduced pressure until a uniform film was formed on the inner wall of the round bottom flask. Add 20 mL of an aqueous solution dissolved with 80 mg of Tween-60 and 40 mg of aluminum lactate into the flask in an uninterrupted micro liquid column (0.3 mm in diameter), and stir magnetically for 6 h at 1200 r / min. Then, at room temperature, sonicate in an ultrasonic generator for 10 minutes to obtain a mixed solution of nanoliposomes wrapped with aluminum lactate. Place the mixed solution in a dialysis bag with a cut-off molecular weight of 8,000-12,000, and dialyze in PBS buffer solution (pH=7.4) at 4°C for 24 hours to remove unencapsulated aluminum lactate to obtain aluminum l...

Embodiment 3

[0030]Accurately weigh 100 mg of lecithin, 50 mg of cholesterol, and 10 mg of vitamin E into a 50 mL round bottom flask, add 10 mL of a mixed solvent of anhydrous methanol and chloroform with a volume ratio of 1.5, and shake to dissolve. At 60°C, the mixed solvent was evaporated on a rotary evaporator at a rate of 85 r / min under reduced pressure until a uniform film was formed on the inner wall of the round bottom flask. Add 15 mL of an aqueous solution containing 40 mg of polysorbate-80 and 40 mg of aluminum lactate into the flask in an uninterrupted micro liquid column (0.4 mm in diameter), and stir magnetically for 5 h at 500 r / min. Then, at room temperature, sonicate in an ultrasonic generator for 20 minutes to obtain a mixed solution of nanoliposomes wrapped with aluminum lactate. Place the mixed solution in a dialysis bag with a cut-off molecular weight of 8,000-12,000, and dialyze in a PBS buffer solution (pH=7.4) at 0°C for 48 hours to remove unencapsulated aluminum la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com