Method for baking tobacco leaves of honghua dajinyuan (Chinese character) variety by use of closed tobacco curing barn

A technology of safflower big gold yuan and flue-cured tobacco room, which is applied in the field of tobacco leaf processing, can solve problems such as poor quality and long curing time, reduce labor intensity and curing cost, avoid mildew of tobacco leaves, and shorten curing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

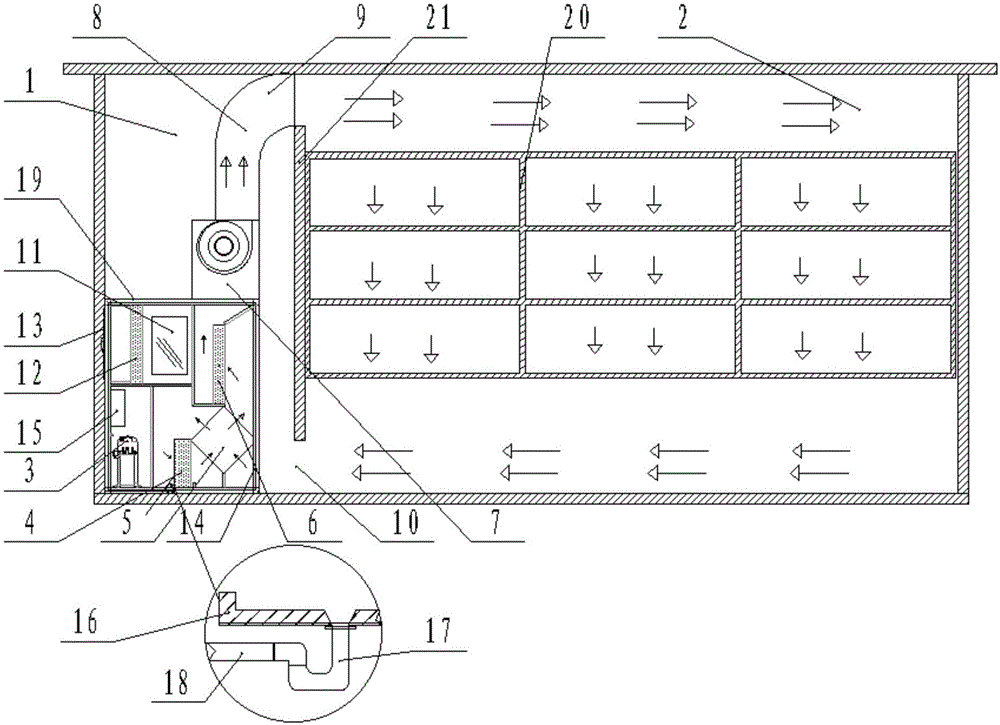

Image

Examples

Embodiment 1

[0018] A method for roasting Honghua Dajinyuan variety tobacco leaves in a closed tobacco curing room, the method comprising the following steps: a yellowing period, a color-fixing period and a gluten-drying period;

[0019] Yellowing period: Place the leaves of the Honghua Dajinyuan variety in a closed flue-cured room, and use a dehumidification heat pump to bake them at a rate of 1.5°C / hour to a dry bulb temperature of 34°C and a wet bulb temperature of 32°C , kept for 22 hours, until the top tobacco leaves turned yellow by more than 40%, then raised the dry bulb temperature to 38°C and wet bulb temperature to 35°C at a heating rate of 1°C / hour, and kept for 25 hours; The heating rate is such that the dry bulb temperature reaches 43° C. and the wet bulb temperature reaches 34° C., and keeps for 18 hours until the tobacco leaves turn yellow.

[0020] Color fixation period: after the end of the yellowing period, raise the temperature of the dry bulb to 52℃ and the temperature ...

Embodiment 2

[0023] A method for roasting Honghua Dajinyuan variety tobacco leaves in a closed tobacco curing room, the method comprising the following steps: a yellowing period, a color-fixing period and a gluten-drying period;

[0024] Yellowing period: Put the leaves of Honghua Dajinyuan variety in a closed flue-cured room, and use a dehumidification heat pump to bake them at a heating rate of 1°C / hour until the dry bulb temperature reaches 36°C and the wet bulb temperature reaches 35°C , kept for 25 hours, until the top tobacco leaves turned yellow by more than 40%, and then the dry bulb temperature was raised to 39°C and the wet bulb temperature to 36°C at a heating rate of 0.5°C / hour, and kept for 30 hours; The heating rate is such that the dry bulb temperature reaches 43°C and the wet bulb temperature reaches 36°C, and the temperature is maintained for 16 hours until the tobacco leaves turn yellow.

[0025] Color fixation period: after the end of the yellowing period, raise the temp...

Embodiment 3

[0028] A method for roasting Honghua Dajinyuan variety tobacco leaves in a closed tobacco curing room, the method comprising the following steps: a yellowing period, a color-fixing period and a gluten-drying period;

[0029] Yellowing period: Place the leaves of the Honghua Dajinyuan variety in a closed flue-cured room, and use a dehumidification heat pump to bake them at a rate of 2°C / hour to a dry bulb temperature of 33°C and a wet bulb temperature of 30°C , kept for 20 hours, until the top tobacco leaves turned yellow by more than 40%, then raised the dry bulb temperature to 39°C and wet bulb temperature to 32°C at a heating rate of 1.5°C / hour, and kept for 20 hours; The heating rate is such that the dry bulb temperature reaches 42° C. and the wet bulb temperature reaches 33° C., and keeps for 20 hours until the tobacco leaves turn yellow.

[0030] Color fixation period: after the end of the yellowing period, raise the temperature of the dry bulb to 50°C and the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com