Polymer lithium battery vacuum baking tunnel furnace and production technology

A soft-pack lithium battery and tunnel furnace technology, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems of low production efficiency and high cost, so as to improve production efficiency, reduce costs, and shorten the drying time. The effect of baking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

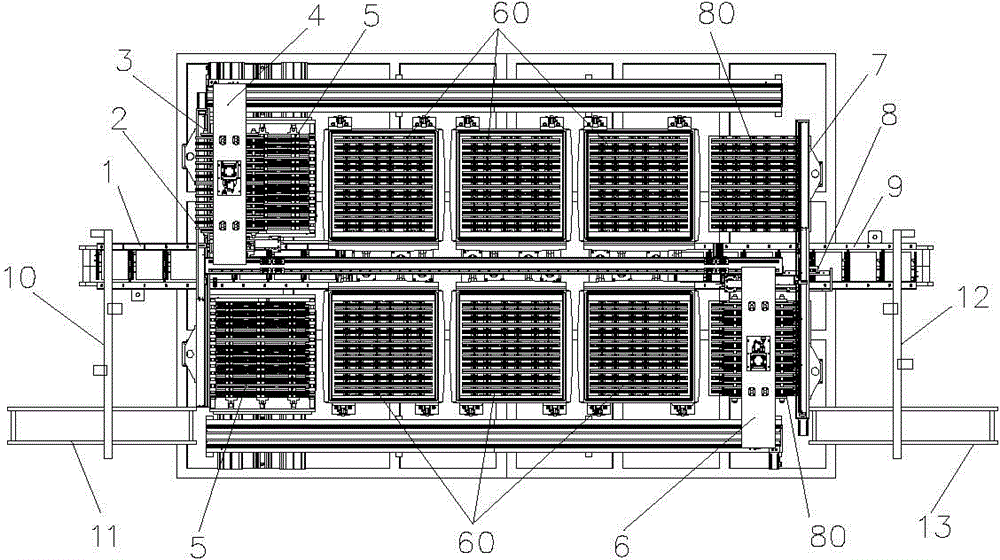

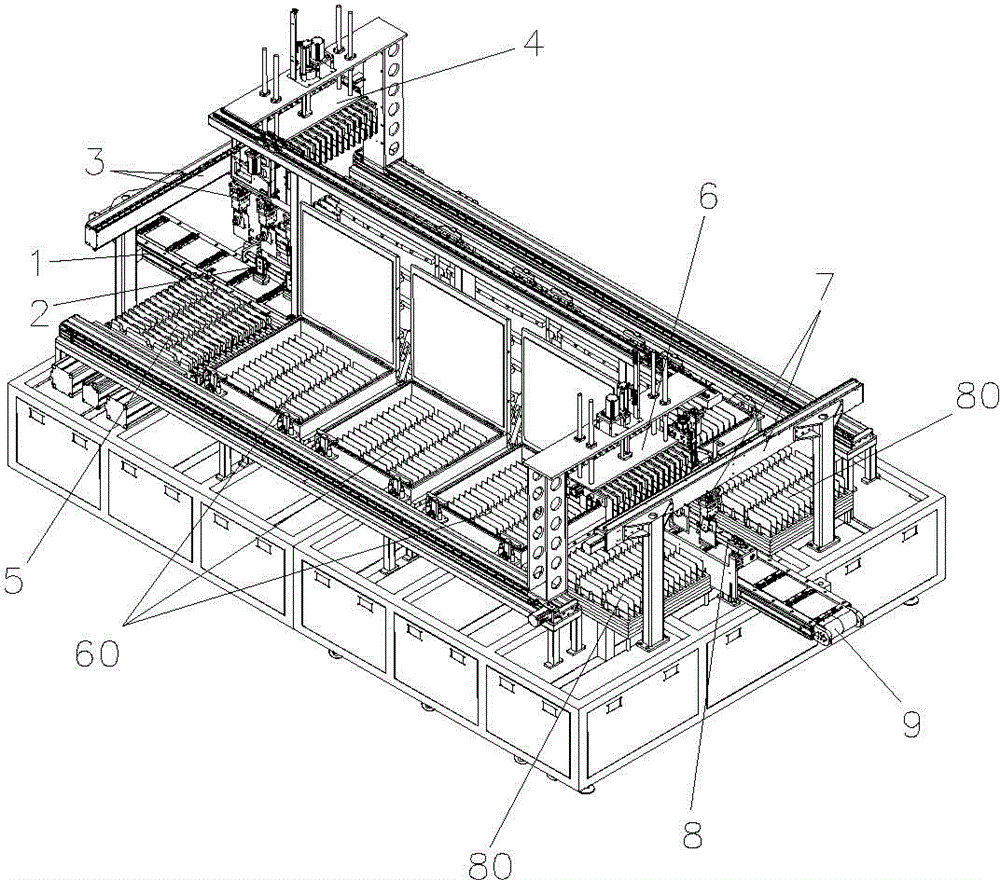

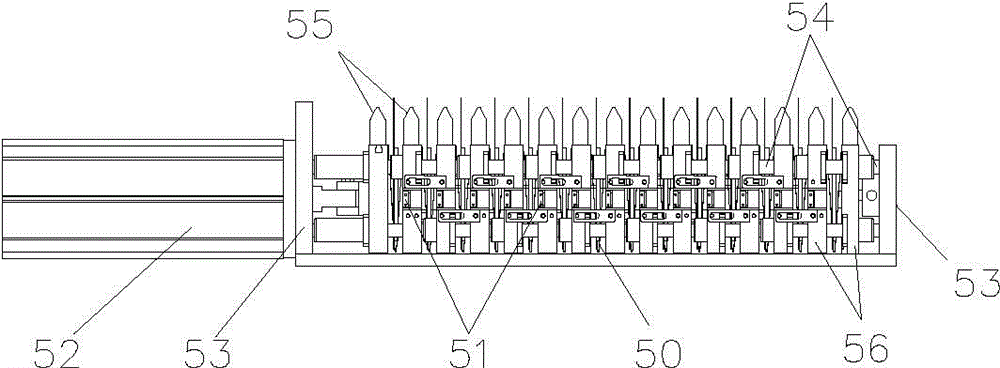

[0038] Such as Figure 1 to Figure 8As shown, the vacuum baking tunnel furnace for the soft-packed lithium battery of the present invention includes a vacuum baking tunnel furnace device, and the vacuum baking tunnel furnace device includes two contact heating mechanisms 5 opposite to each other. Two blanking buffer fixtures 80, three vacuum ovens 60 arranged in sequence between the left contact heating mechanism 5 and the left blanking cache fixture 80, the right contact heating mechanism 5 and the right blanking There are three sequentially arranged vacuum ovens 60 arranged between the buffer fixtures 80; a feeding transfer belt 1 is arranged between the two contact heating mechanisms 5 facing left and right, and a feeding transfer belt 1 is arranged above The feeding turning mechanism 2 that changes the battery on the feeding transfer pull belt 1 from lying flat to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com