Low temperature quick-drying amino paint for automobile chassis and production method thereof

An automobile chassis and amino technology, applied in coatings, polyester coatings, etc., can solve the problems of poor chassis protection, short salt spray resistance time, and long coating time, and achieve good leveling, protective performance and The effect of improving the coating efficiency and delaying the aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

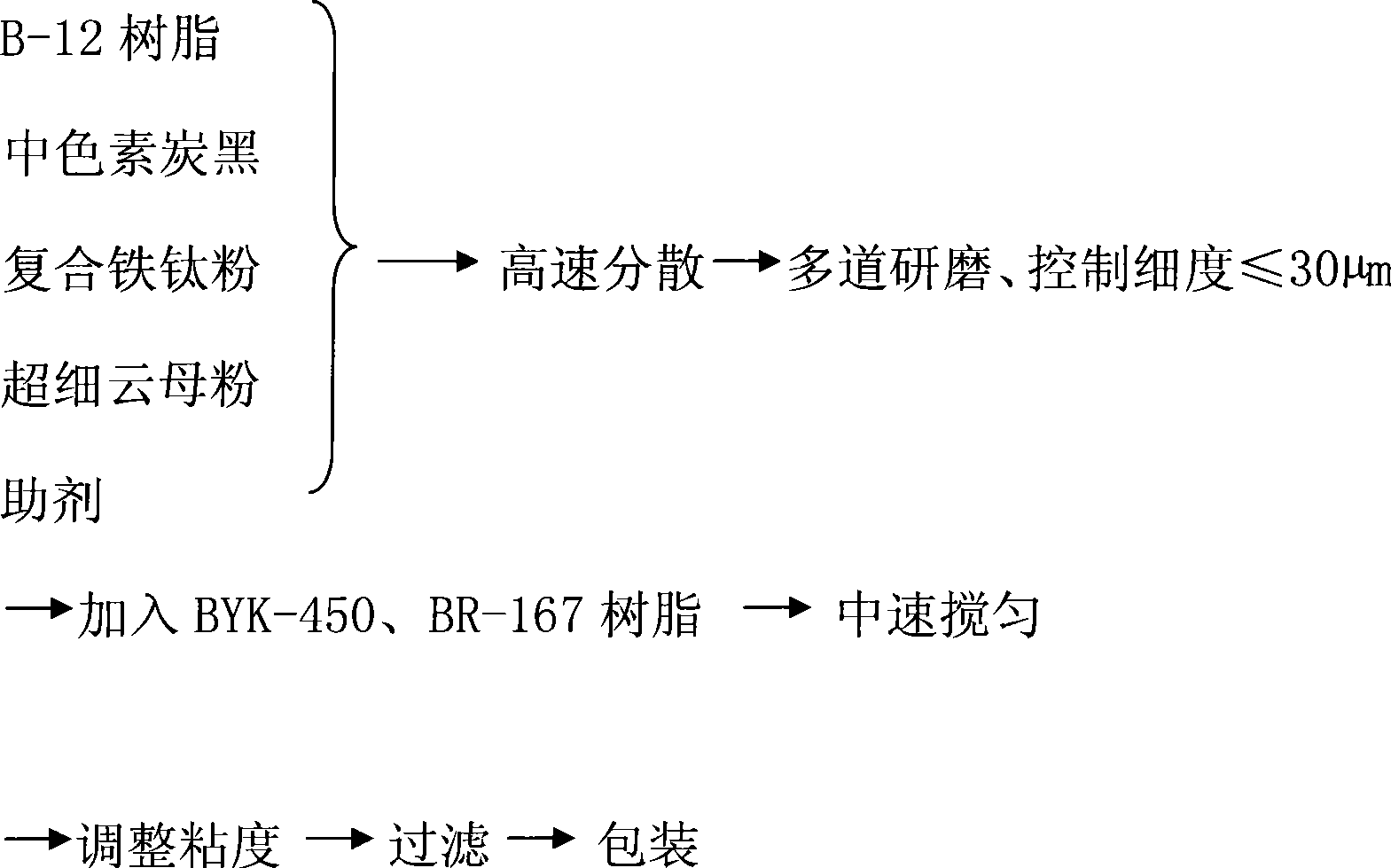

Method used

Image

Examples

Embodiment Construction

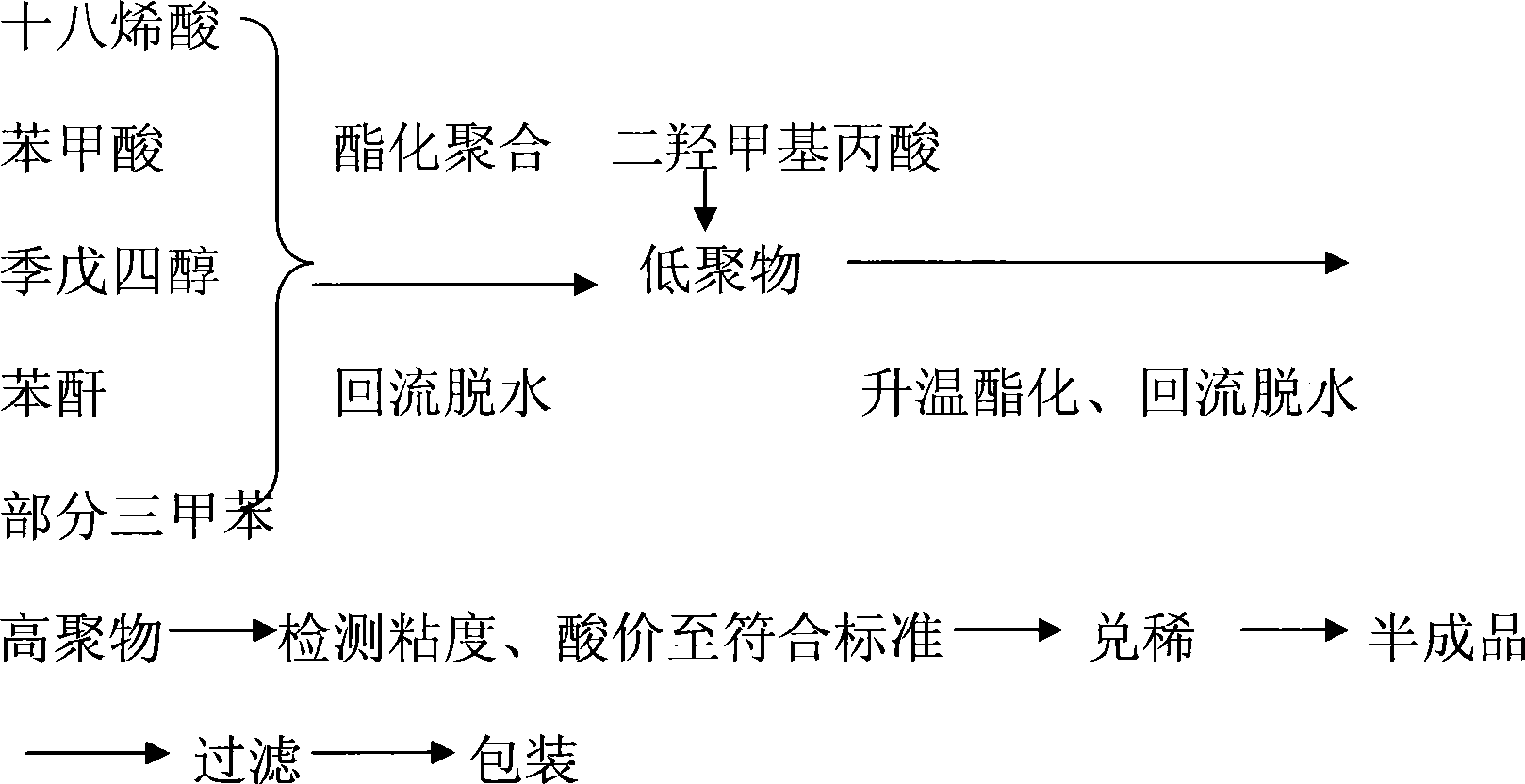

[0056] 1. The main raw material of B-12 resin

[0057] Octadecenic acid (industrial product), benzoic acid (industrial product), phthalic anhydride (industrial product), dimethylolpropionic acid (industrial product), pentaerythritol (industrial product), trimethylbenzene (industrial product), butanol (industrial product) product), composite iron-titanium powder (industrial product), superfine mica powder (industrial product), medium pigment 3# carbon black (industrial product), BYK-450 (imported from Germany).

[0058] 2. The weight ratio of B-12 resin raw material components:

[0059] Raw material name Specification Percent composition

[0060] Octadenoic acid, AV≥198mgKOH / g 16-22

[0061] Benzoic acid 99% 3-7

[0062] Pentaerythritol 99.5% 9-13

[0063] Phthalic anhydride 99.5% 12-17

[0064] Dimethylolpropionic acid 99.5% 3-6

[0065] Trimethylbenzene industrial products 45-55

[0066] 3. Preparation of B-12 resin:

[0067] ①. Add octadecenoic acid, benzoic acid, pent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com