Water-based glass coating

A glass coating, water-based technology, applied in the field of coatings, can solve problems such as damage to human health, poor tolerance, poor toughness and wear resistance, and achieve the effect of improving production efficiency and shortening baking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

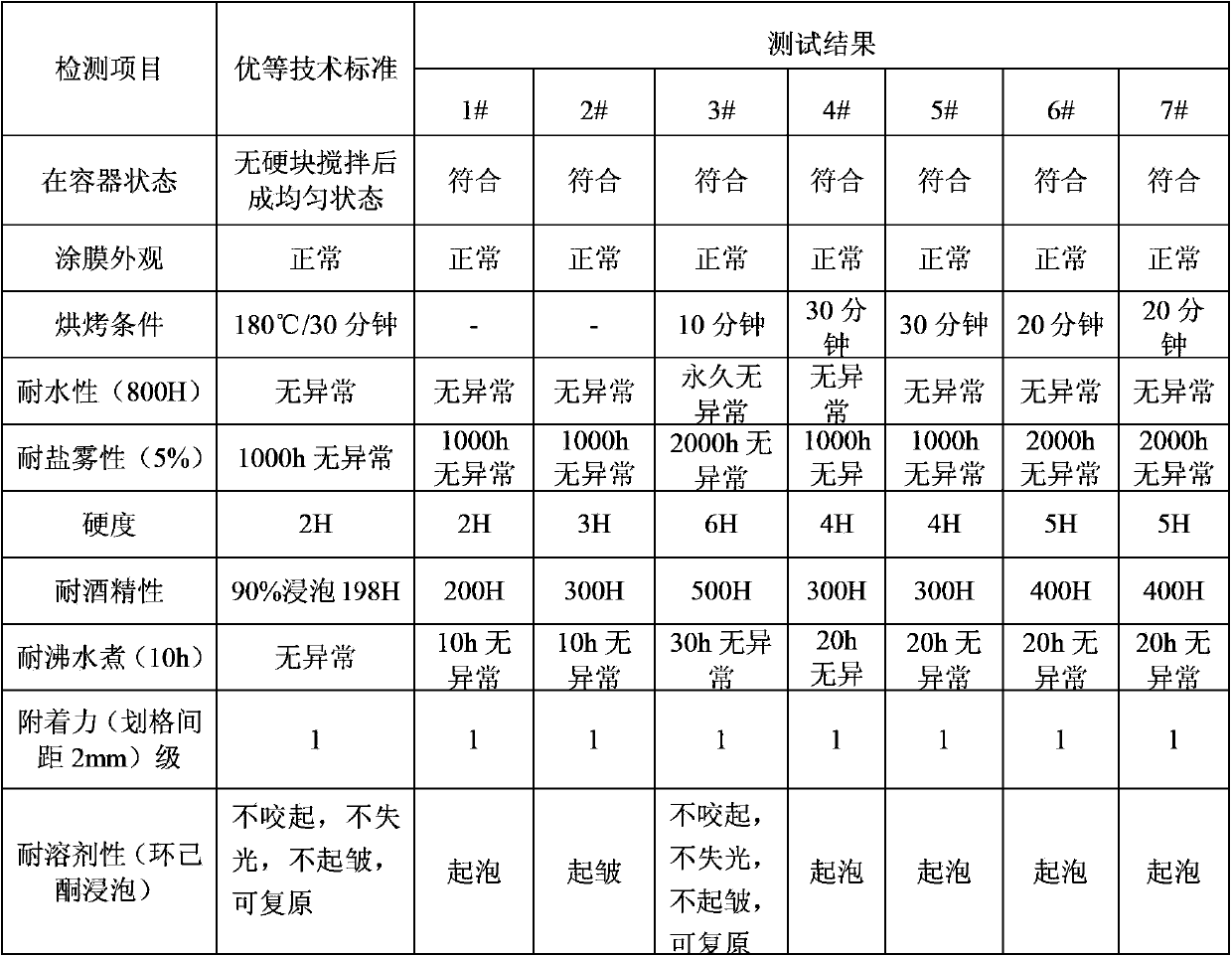

Examples

Embodiment 1

[0054] A preparation method of water-based glass coating, the specific operation steps are: adding the components acrylic resin, epoxy polyurethane synthetic resin, coupling agent and amino resin in the formula to the reaction container and mixing in sequence, and using a stirrer at a stirring speed of 1200r / min After stirring and dispersing at the speed of 20 minutes, add wetting agent, leveling agent, thickener and defoamer to the dispersed mixed components in sequence, stir and disperse for 15 minutes at a stirring speed of 800r / min, and then add curing Agent and deionized water, stirring and dispersing for 5 minutes at a stirring speed of 300r / min, the finished water-based glass coating can be obtained. Components in the present invention all adopt existing products, which can be the product models listed in the present invention, but are not limited to the product models in the present invention.

[0055] In the present invention, the acrylic resin is a water-based acryli...

Embodiment 2

[0066] Same as Example 1, the difference is:

[0067] The mass percentages of acrylic resin, epoxy polyurethane synthetic resin, coupling agent, amino resin, wetting agent, leveling agent, thickener, defoamer, curing agent and deionized water are: 32%, 28%, 1%, 13%, 0.1%, 1%, 0.5%, 0.4%, 9%, 15%.

Embodiment 3

[0069] Same as Example 1, the difference is:

[0070] The mass percentages of acrylic resin, epoxy polyurethane synthetic resin, coupling agent, amino resin, wetting agent, leveling agent, thickener, defoamer, curing agent and deionized water are: 35%, 30%, 2%, 15%, 0.2%, 1.2%, 1%, 0.5%, 10%, 5.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com