Vacuum drying oven

A vacuum drying furnace and vacuum furnace technology, which is applied in the direction of drying solid materials, local agitation dryers, and static material dryers, etc., can solve the problems of difficult to completely remove moisture, reduce drying efficiency, and reduce drying effect, and achieve shortened drying time. The effect of baking time, avoiding dead angle of drying, and fast heat cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

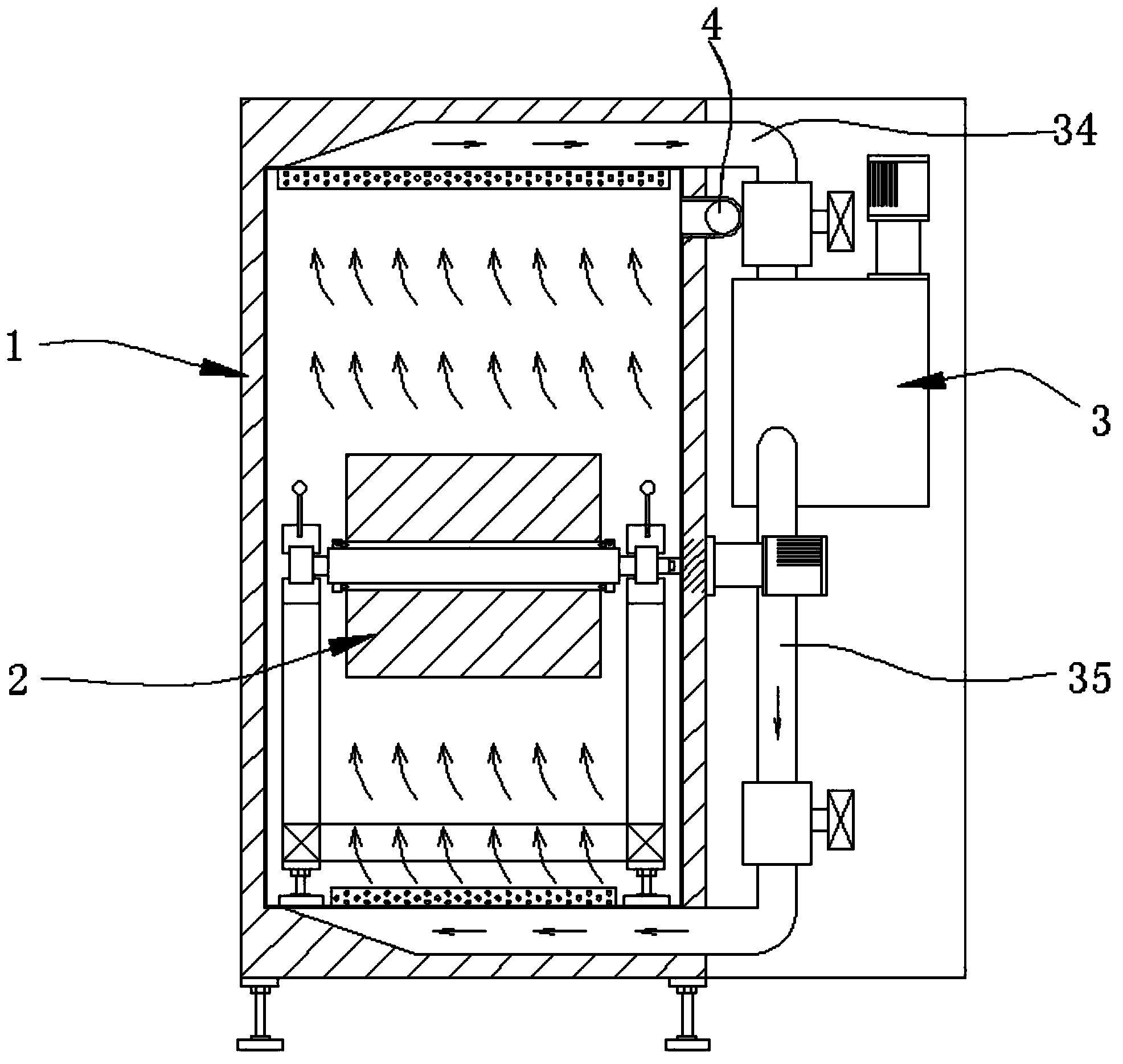

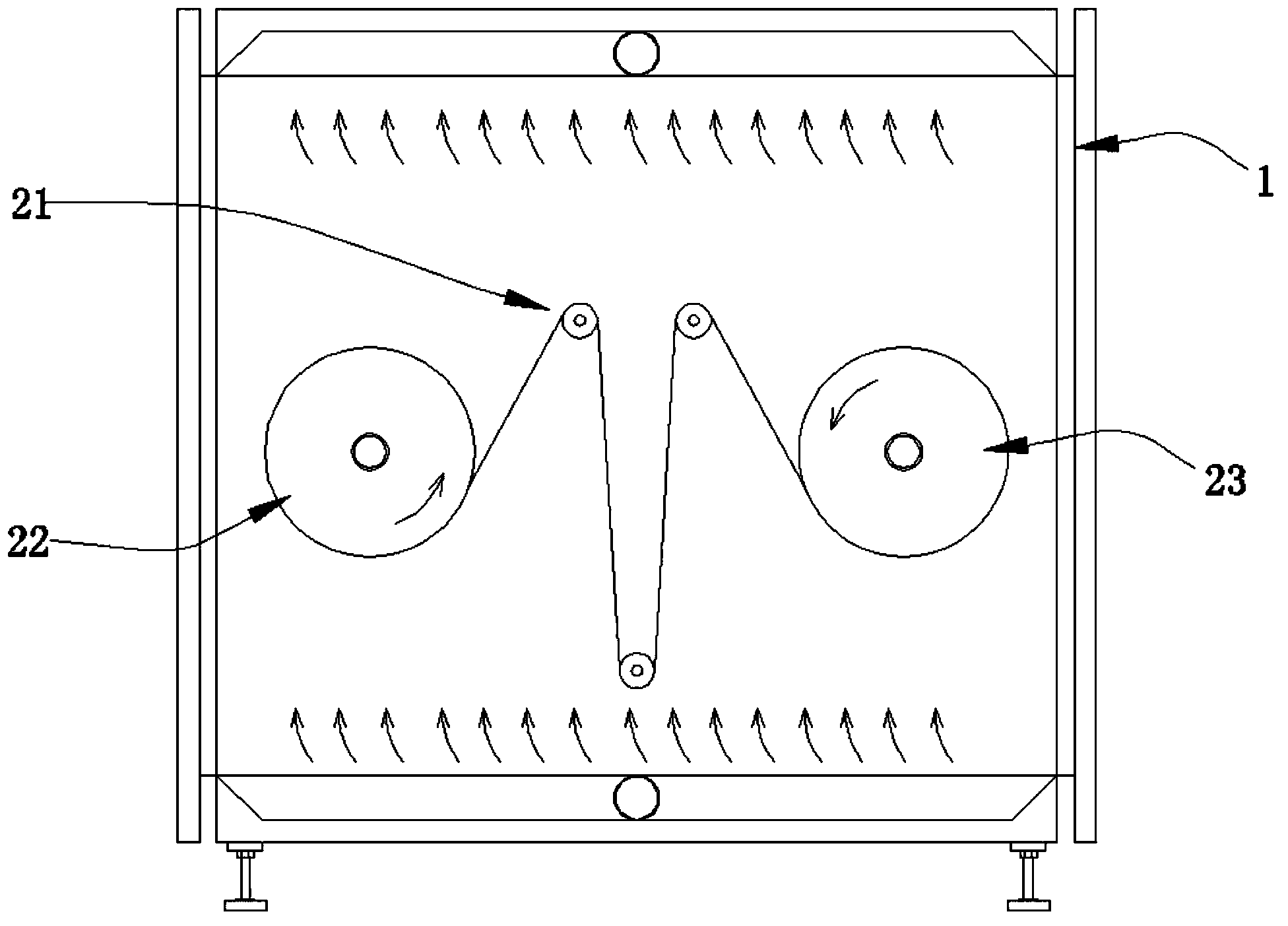

[0022] see Figure 1 to Figure 4 , a vacuum drying furnace provided in this embodiment, which includes a vacuum furnace body 1, in which at least one winding and unwinding mechanism 2 is provided, and on the outer wall of the vacuum furnace body 1 there is at least one conveyor Wind lighting device 3.

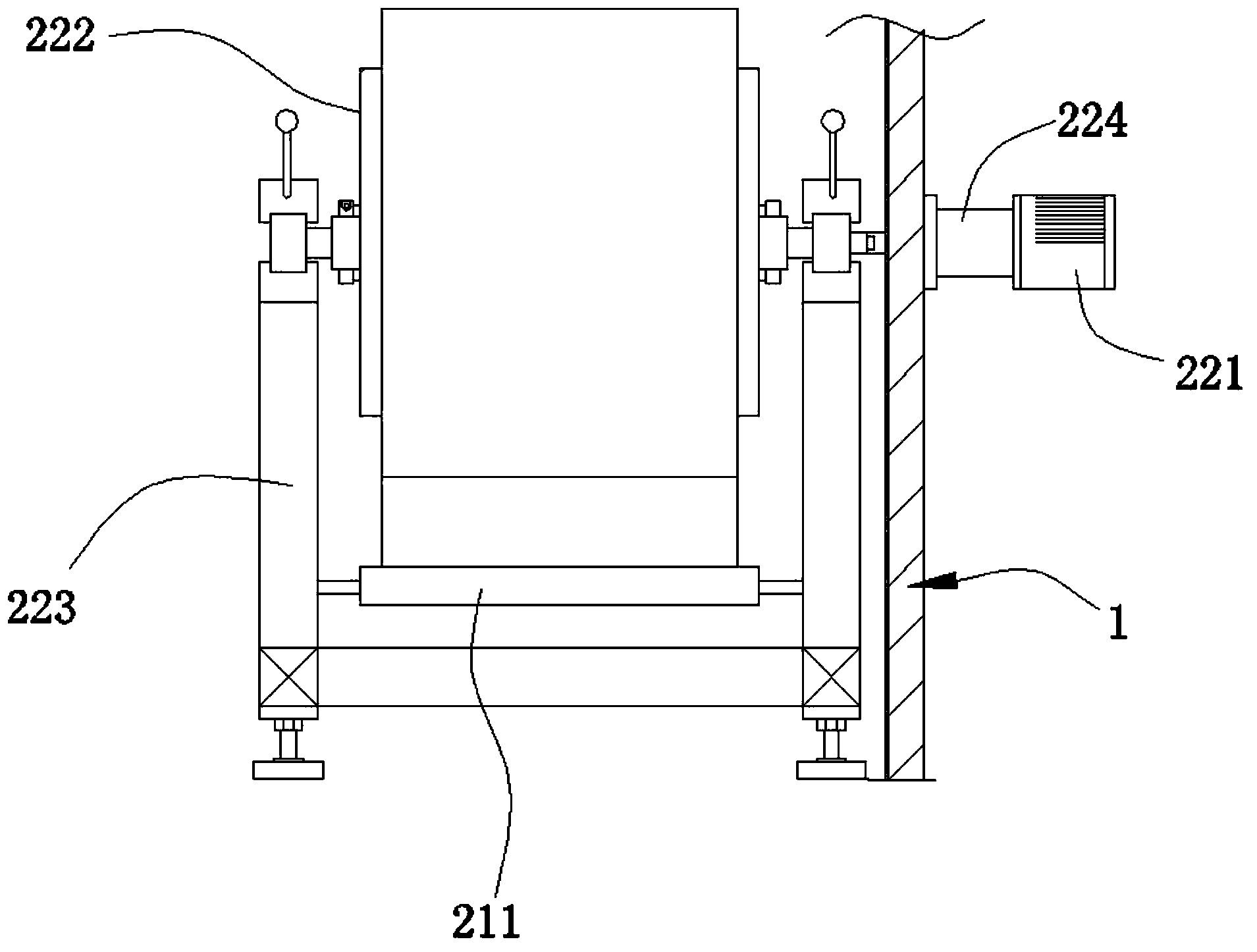

[0023] The rewinding and unwinding mechanism 2 includes a guide assembly 21, an unwinding assembly 22, and a rewinding assembly. The unwinding assembly 22 and the rewinding assembly are arranged at intervals and at the same level. The guide assembly 21 is arranged on the unwinding assembly. 22 and between the winding assembly.

[0024] The uncoiling assembly 22 includes an uncoiling motor 221 and an uncoiling roller 222, the uncoiling roller 222 is arranged in the vacuum furnace body 1 through a bracket 223, and the uncoiling motor 221 is fixed in the vacuum furnace through an axial sealing device 224 The outer wall of the body 1, and the drive shaft of the unwinding motor 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com