Method for drying lithium ion battery or battery pole piece

A technology for lithium-ion batteries and battery pole pieces, which is applied in drying, method combination to dry solid materials, drying solid materials, etc., to achieve the effects of increasing capacity, shortening baking time, and improving equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

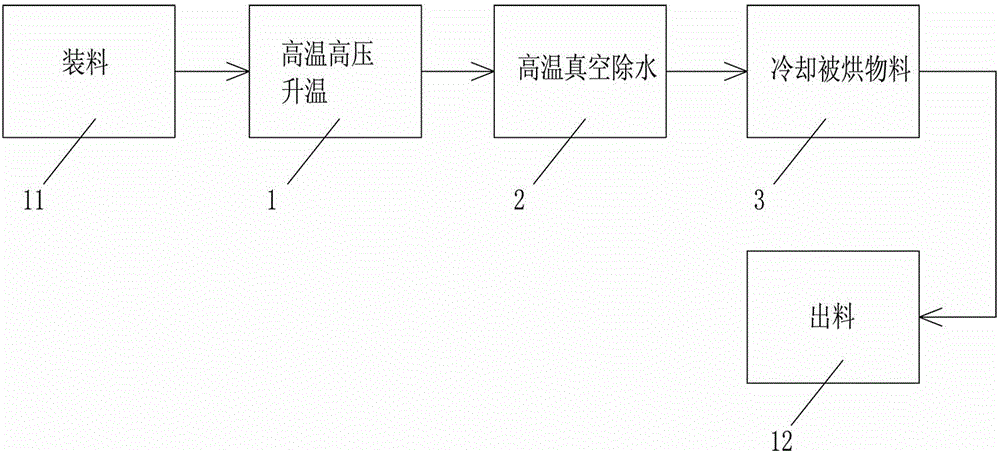

[0023] See figure 1 , figure 1 Disclosed is a method for drying lithium-ion batteries or battery pole pieces, comprising the following steps,

[0024] (11), the charging step, put the lithium-ion battery or battery pole piece to be processed into the working box;

[0025] (1) In the high-pressure heating step, within 20-60 minutes, the temperature in the working box equipped with an internal circulation fan is raised to the first predetermined temperature, and the pressure in the working box is raised to the first predetermined pressure by using a protective gas, keeping 5-20 minutes; the first predetermined temperature is between 80 degrees Celsius and 115 degrees Celsius, or between 121 degrees Celsius and 200 degrees Celsius; the first predetermined pressure is between 10Kpa and 500Kpa; the method of high pressure heating is adopted, because the working box The gas density in the body is high, and the temperature can be raised to the predetermined temperature in about 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com