High-efficiency baking method for improving appearance quality of K326 variety of tobacco leaves

A curing method and appearance quality technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of large color difference between the front and back of tobacco leaves, poor appearance quality of tobacco leaves, and large pollutant emissions, so as to avoid curing black smoke and curing Effects of green smoke, improvement of appearance quality, and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

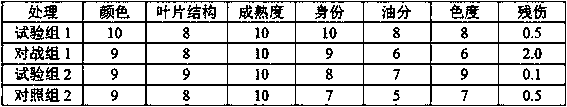

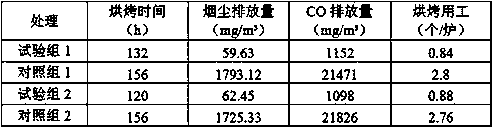

Embodiment 1

[0030] S100: Harvesting the tobacco leaves of the K326 tobacco plant that is suitable for ripening in Jiuxi Town, Jiangchuan District, Yuxi City.

[0031] S200: Weave the harvested tobacco leaves according to the principles of the same stalk, same quality, same position, and appropriate density, and then use the same furnace and same quality principle to weave the stems at a rate of 42 kg / m 3 The density is loaded into the ascending dense oven to 96% of the volume to be baked.

[0032] S300: Use biomass fuel to bake in stages, including early yellowing control, mid-yellowing control and late yellowing control. The initial yellowing control increases the dry bulb temperature from room temperature at a heating rate of 1°C / h. to 34°C, adjust the wet bulb temperature from room temperature to 32°C, and then bake at a stable dry and wet bulb temperature for 16 hours until the tip of the tobacco leaves in the high temperature layer turns yellow obviously; the middle stage of yellowin...

Embodiment 2

[0036] S100: Harvesting the tobacco leaves of the K326 tobacco plant that is suitable for ripening in Jiuxi Town, Jiangchuan District, Yuxi City.

[0037] S200: Weave the harvested tobacco leaves according to the principles of the same stalk, same quality, same position, and appropriate density, and then put them into the ascending dense barn at a density of 44 kg / m3 according to the same furnace and homogeneous principle to reach the volume. 97% to be baked.

[0038] S300: Use biomass fuel to bake in stages, including early yellowing control, mid-yellowing control and late yellowing control. The initial yellowing control increases the dry bulb temperature from room temperature at a heating rate of 1°C / h. to 35°C, adjust the wet bulb temperature from room temperature to 33°C, and then bake at a stable dry and wet bulb temperature for 12 hours until the tip of the tobacco leaves in the high temperature layer turns yellow obviously; the middle stage of yellowing is controlled at...

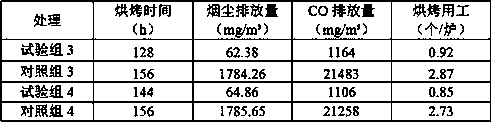

Embodiment 3

[0042] S100: Harvesting the tobacco leaves of the K326 tobacco plant that is suitable for ripening in Jiuxi Town, Jiangchuan District, Yuxi City.

[0043] S200: It will be the same as S200 in Embodiment 1.

[0044] S300: use coal as fuel to bake in stages, and the others are the same as S300 in Embodiment 1.

[0045] S400: use coal as fuel to bake in stages, and the others are consistent with S400 in Embodiment 1.

[0046] S500: use coal as fuel to bake in stages, and the others are the same as S500 in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com