Marine impact-resistant foamed aluminum-based composite board and preparation method thereof

A composite sheet and aluminum foam technology, applied in coatings, polyurea/polyurethane coatings, filling slurry, etc., can solve the problem that the impact resistance of composite materials is difficult to apply to local impact loads, and the brittle fracture of pore walls cannot be completely eliminated. Process and other issues, to improve the overall structural strength of foamed aluminum materials, good durability and reliability, and solve the effect of brittle fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

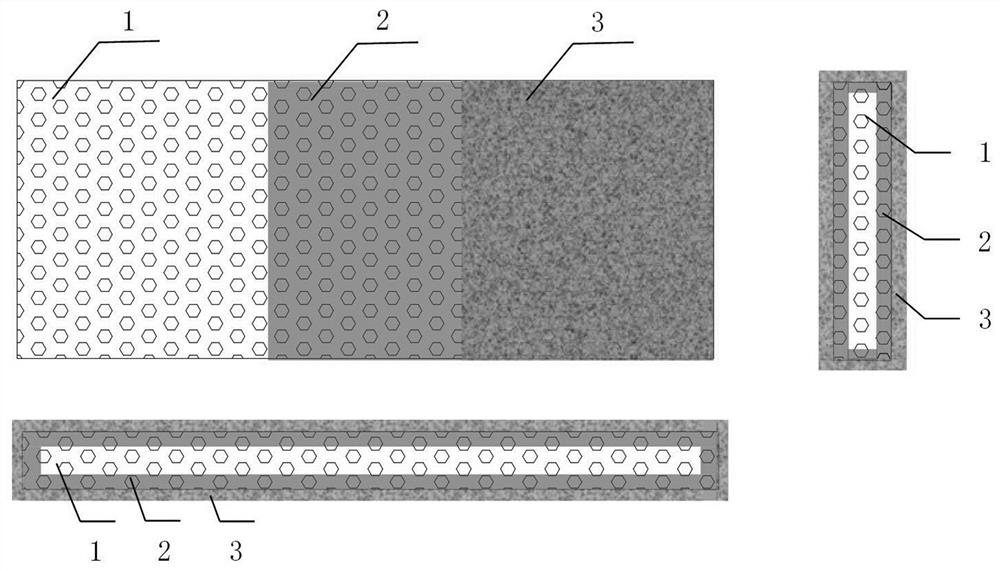

Image

Examples

Embodiment 1

[0027] The density of the foamed aluminum substrate used is 0.2g / cm 3 ; Fully mix 50ml of two-component polyurethane A (diisocyanate) and 10ml of two-component polyurethane B (a mixture of polyether polyol and polyester polyol) to obtain a mixed solution, and use a sprayer to mix the obtained mixture The liquid is sprayed on the surface of the foamed aluminum substrate to make a polyurethane infiltration layer, so that the pores on the surface of the foamed aluminum are completely filled, and placed for 10 hours to cure to obtain a preliminary sample block. After curing, add 50% volume of SiC particles to the obtained mixed solution. , After stirring evenly, a solid-liquid mixture is obtained, and the obtained solid-liquid mixture is sprayed on the surface of the preliminary sample block with a spraying machine, and the spray thickness is 0.5mm;

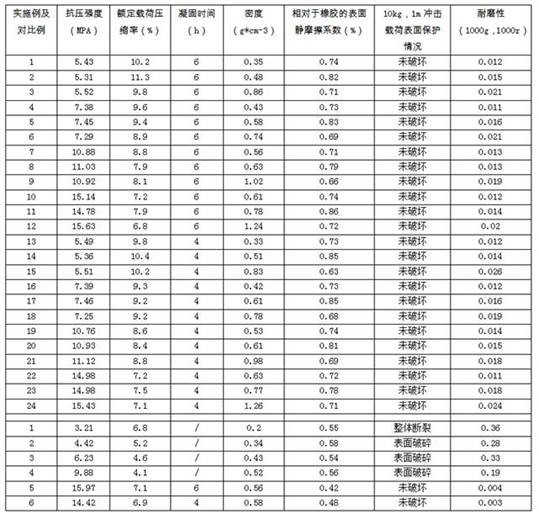

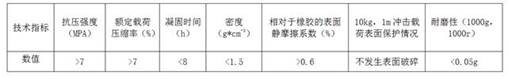

Embodiment 2-24

[0029] Compared with Example 1, the wear-resistant particles are different, the density of the foamed aluminum base material is different, and the polyurethane base material is different. The details of the raw materials used in Examples 1-24 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com