Aluminum alloy aluminum rod and manufacturing method for making aluminum lamps from the aluminum alloy aluminum rod

A manufacturing method, aluminum alloy technology, applied in the direction of metal extrusion dies, etc., can solve the problems of less than 30% success rate, high scrapping rate of extrusion dies, expensive die costs, etc., to reduce alloy content, good application effect, prevent The effect of brittle fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

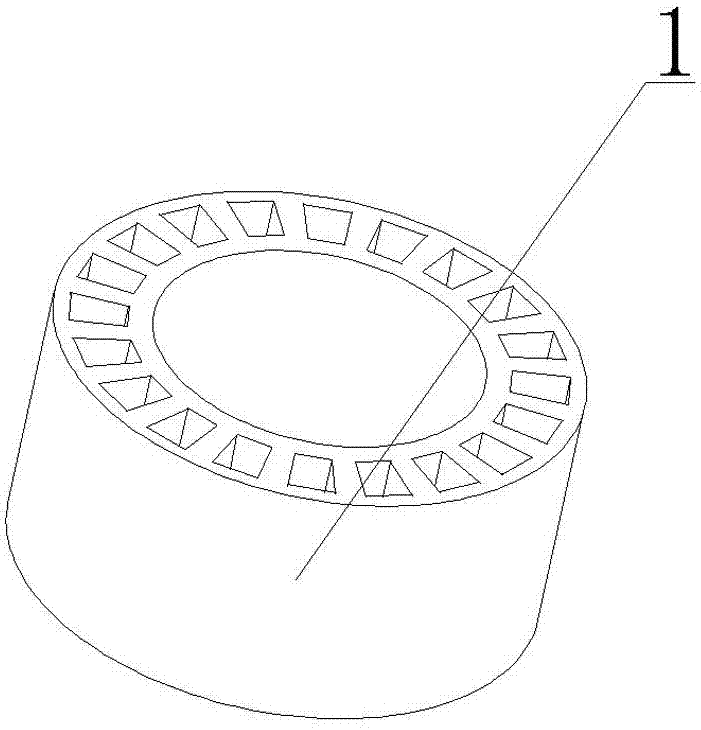

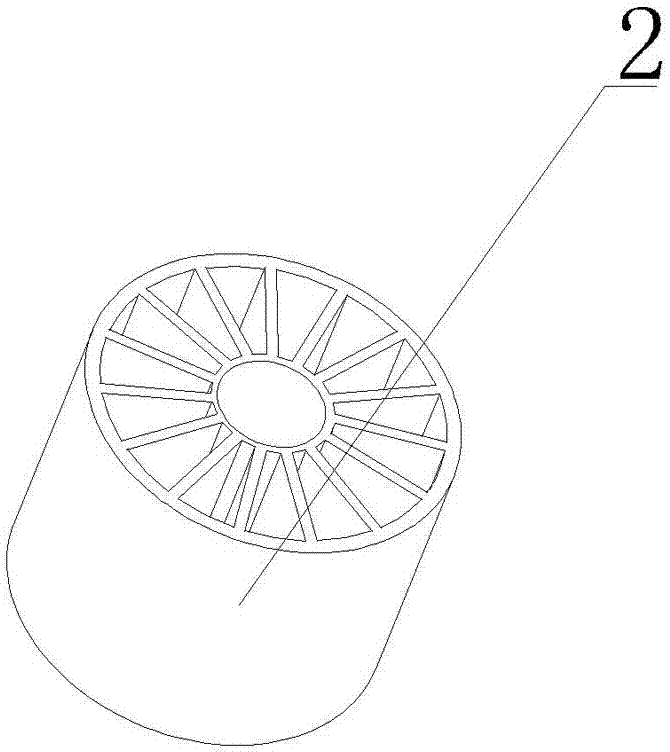

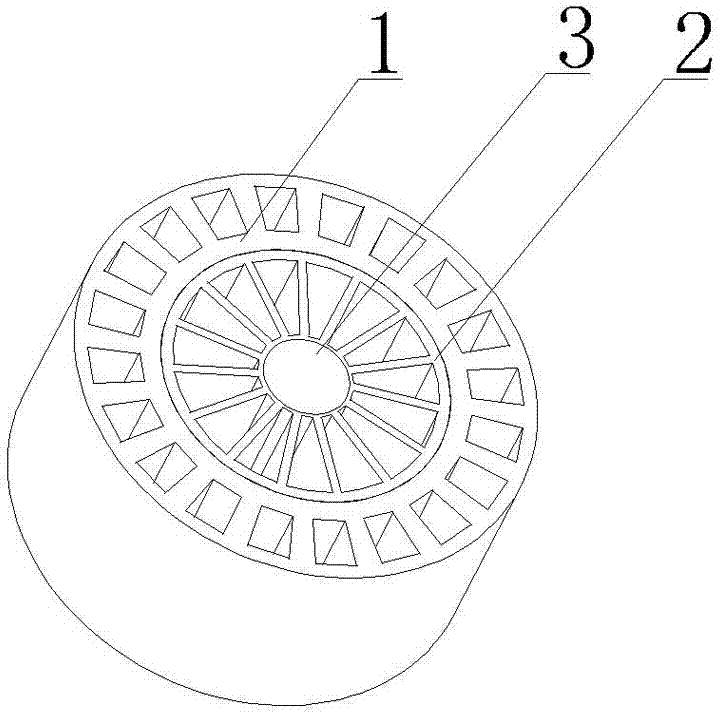

[0014] The following specific embodiments are described in conjunction with the accompanying drawings, as Figure 1-Figure 3 Shown: This aluminum alloy aluminum rod includes the following components in weight percentage: Mg is 0.45-0.55, Si is 0.2-0.4, Fe<0.1, Cu<0.1, Mn<0.1, Zn<0.1, and the balance is Al.

[0015] In the above examples, the content of Si, Zn and Mn in the composition of the aluminum alloy aluminum rod ensures the strength of the alloy, the ratio of Mg and Cu ensures the surface quality of the product, and the content of Mg can weaken the Fe element. The mechanical properties and surface effects of the aluminum rod meet the requirements, and the application effect is very good.

[0016] The production process of using the aluminum alloy aluminum rod to make a lamp includes the following steps:

[0017] The standard H13 steel is selected as the mold material, and the mold adopts a three-piece combination, which are the bottom mold, the middle mold and the mask...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com