Installation, connection and reinforcement device for building steel structure

A reinforcement device and construction steel technology, applied in building components, building structures, buildings, etc., can solve problems such as collapse, poor structural strength and compression resistance, and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

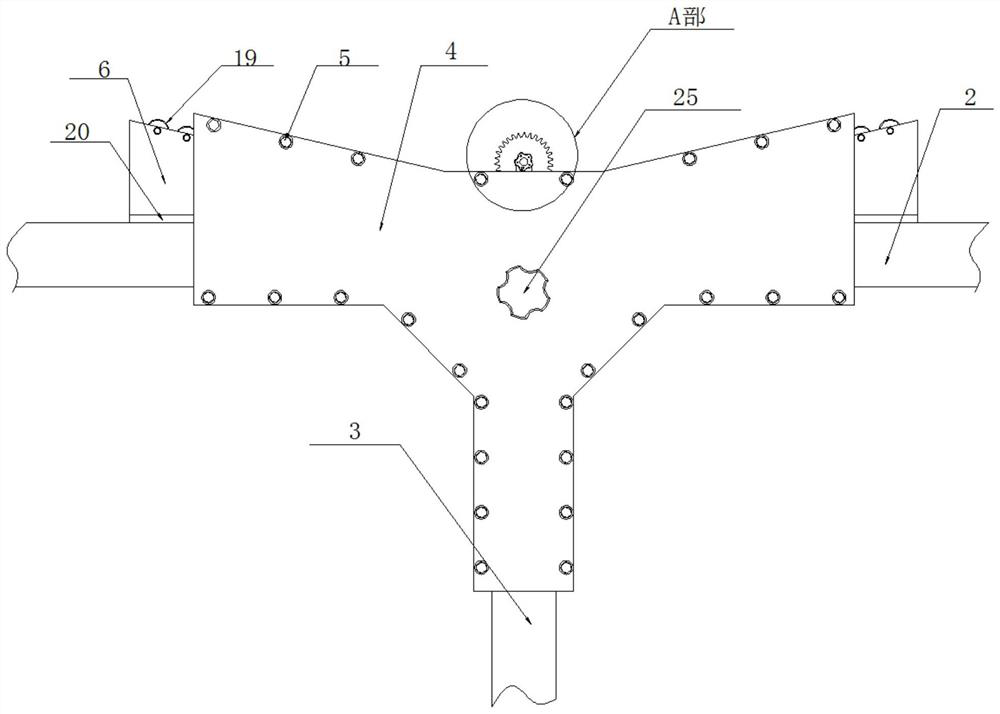

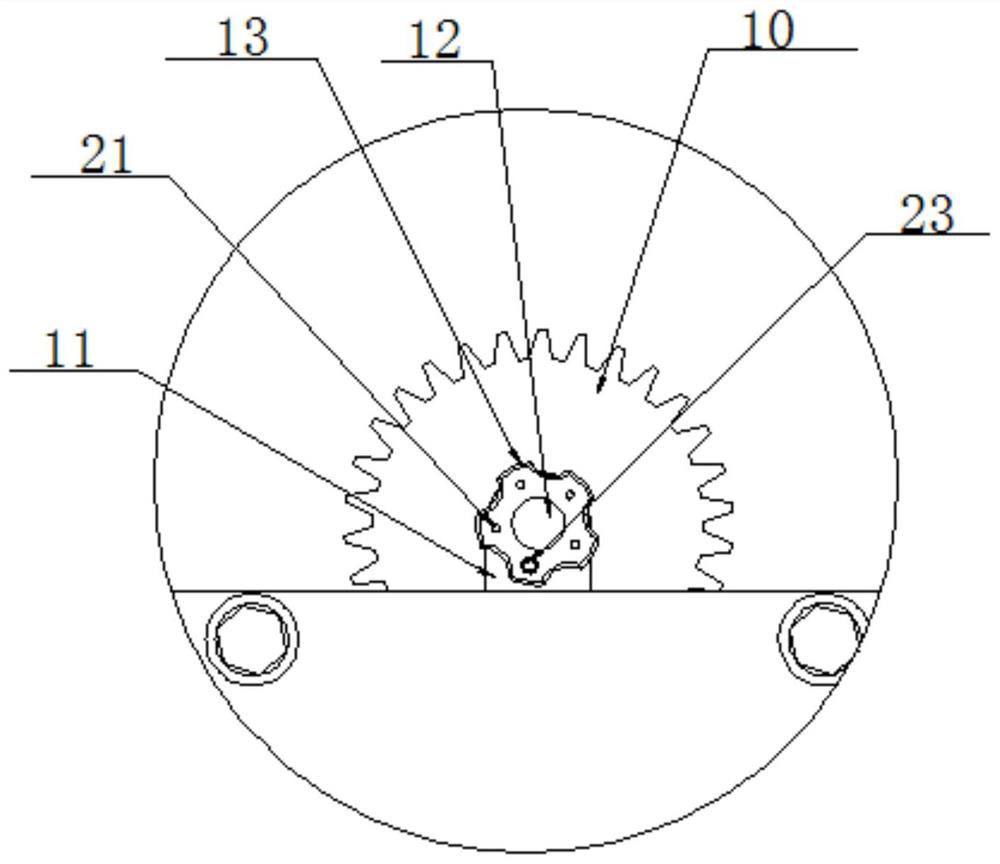

[0024] see as Figure 1-Figure 5 As shown, the technical solution adopted in this specific embodiment is: it includes a housing 1, a fixed cover 4, a locking bolt 5, a wedge 6, a screw 7, an internally threaded pipe 8, a worm wheel 10 and a worm 9; the housing 1 It is arranged in a "T" shape, and the front side of the casing 1 is set in an open shape. The casing 1 is set on the connecting part of the beam body 2 and the column body 3 through the opening end cover on the front side, and the front side wall of the casing 1 is fixed. A fixed cover 4 is provided, and the inner ends of several locking bolts 5 pass through the side wall of the fixed cover 4 through threaded rotation, and are fixedly arranged inside the side wall of the housing 1; the left and right sides of the upper side wall of the housing 1 are To be arranged obliquely upward, the left and right sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com