High-pressure twisting-electric field assistant thermal treatment fine grain method for ZrTiAlV alloy

An electric field-assisted, high-pressure spinning technology is applied in the field of ZrTiAlV alloy fine-grain treatment, which can solve problems such as shortening the heat treatment time of zirconium alloys, and achieve the effect of superior comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

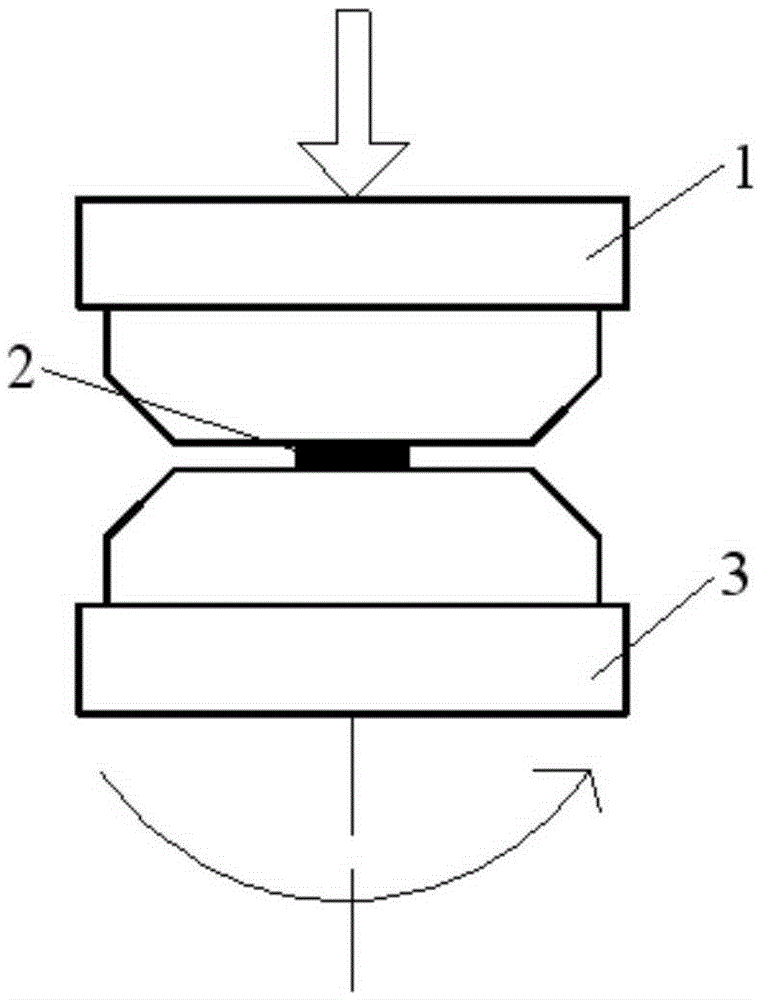

[0016] Put the upper and lower ends of the 47Zr-45Ti-5Al-3V sheet sample 2 with a thickness of 1.5 to 2mm into the upper graphite mold 1 and the lower graphite mold 3 respectively, and place the assembled alloy sample and mold in the discharge plasma In the sintering machine, the upper pressure head goes down to apply a pressure of 5 MPa to the sample, and then the vacuum degree is evacuated to 10 -3 Pa. The specific sintering power supply and pressing pressure are applied to the 47Zr-45Ti-5Al-3V sheet sample by using the upper and lower indenters and energized electrodes. The plasma generated by the pulse current causes the internal ion discharge of the alloy sample to generate heat, and the alloy rapidly Heat up to 600°C for solid solution treatment, then strictly control the temperature and keep it warm for 20 minutes, and finally turn off the power and cool naturally. The plate after solid solution treatment is subjected to high-pressure twisting under a pressure of 4GPa,...

Embodiment 2

[0018] Put the upper and lower ends of the 1.5-2mm thick 47Zr-45Ti-5Al-3V sheet sample into the upper and lower graphite molds respectively, put the assembled alloy sample and mold in the spark plasma sintering machine, The indenter goes down to apply a pressure of 5MPa to the sample, and then pump the vacuum to 10 -3 Pa. The specific sintering power supply and pressing pressure are applied to the 47Zr-45Ti-5Al-3V sheet sample by using the upper and lower indenters and energized electrodes. The plasma generated by the pulse current causes the internal ion discharge of the alloy sample to generate heat, and the alloy rapidly Heat up to 600°C for solid solution treatment, then strictly control the temperature and keep it warm for 20 minutes, and finally turn off the power and cool naturally. The plate after solid solution treatment is subjected to high-pressure twisting under 5GPa pressure to rotate the lower mold at a rotation angle of 360°, and then annealed and recrystallize...

Embodiment 3

[0020] Put the upper and lower ends of the 1.5-2mm thick 47Zr-45Ti-5Al-3V sheet sample into the upper and lower graphite molds respectively, put the assembled alloy sample and mold in the spark plasma sintering machine, The indenter goes down to apply a pressure of 5MPa to the sample, and then pump the vacuum to 10 -3 Pa. The specific sintering power supply and pressing pressure are applied to the 47Zr-45Ti-5Al-3V sheet sample by using the upper and lower indenters and energized electrodes. The plasma generated by the pulse current causes the internal ion discharge of the alloy sample to generate heat, and the alloy rapidly Heat up to 700°C for solid solution treatment, then strictly control the temperature and keep it warm for 20 minutes, and finally turn off the power and let it cool naturally. The plate after solid solution treatment is subjected to high-pressure twisting under a pressure of 4GPa, that is, the lower mold is rotated at a rotation angle of 360°, and then ann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com