Full-automatic ribbon packaging process

A fully automatic technology with packaging, applied in packaging, packaging machines, transportation packaging, etc., can solve the problems of increasing the production cost of cable ties, high labor costs, prolong storage time and service life, improve packaging work efficiency, and prevent cable ties. With the effect of brittle fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

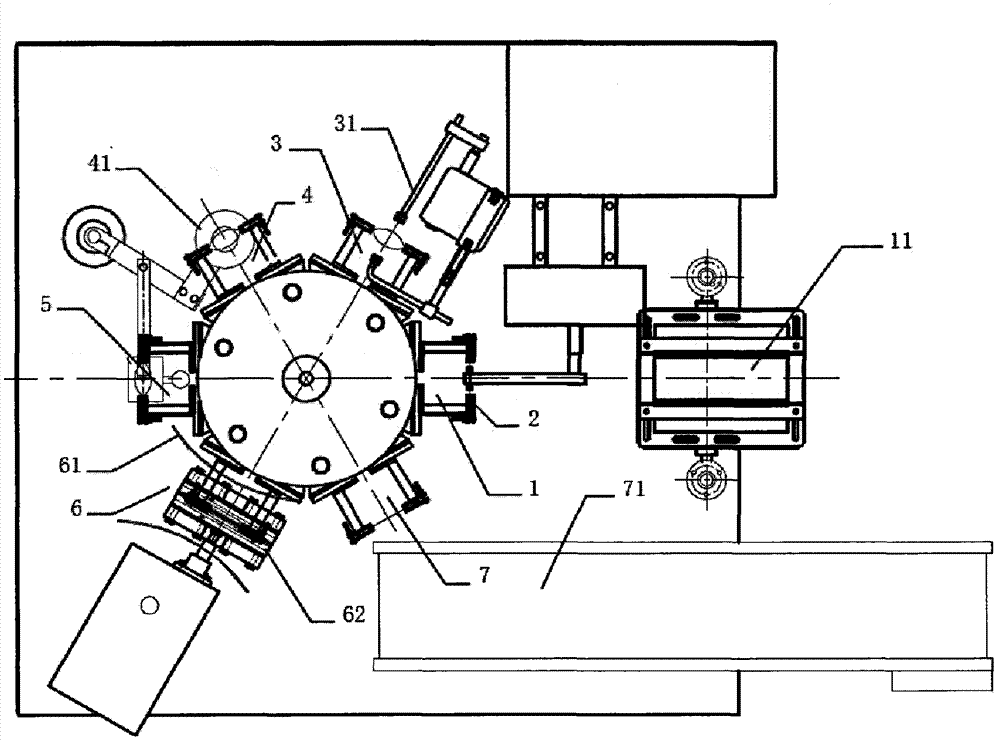

[0014] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0015] Such as figure 1 Shown, the present invention is a kind of fully automatic cable tie packaging process, and it comprises the following steps:

[0016] (1). Bagging: Put the packaging bag with one end sealed into the bag loading station of the fully automatic packaging machine customized for this process. After starting the packaging machine, two pneumatic manipulators will automatically With a suction cup, it goes down to absorb the most surface packaging bag, and lifts it away from the bin 11 to the designated position. After the rotating robot rotates at a certain angle, it is delivered to the suction cup robot, and uses its own bilateral gripping to grip the horizontal two sides of the bag mouth. side, after clamping, rotate to the top of the turntable, and the machine clamps on the indexing plate of the main machine for delivery, and uses the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com