Composite panel for repairing reinforcing con'c body and method of using the same

A prefabricated concrete slab and concrete technology, which is applied in building maintenance, bridge maintenance, bridge reinforcement, etc., can solve the problems of decreased strengthening effect, difficulty in safety supervision, loss of life and property, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with preferred embodiments with reference to the accompanying drawings. Like reference numerals designate corresponding parts throughout the drawings.

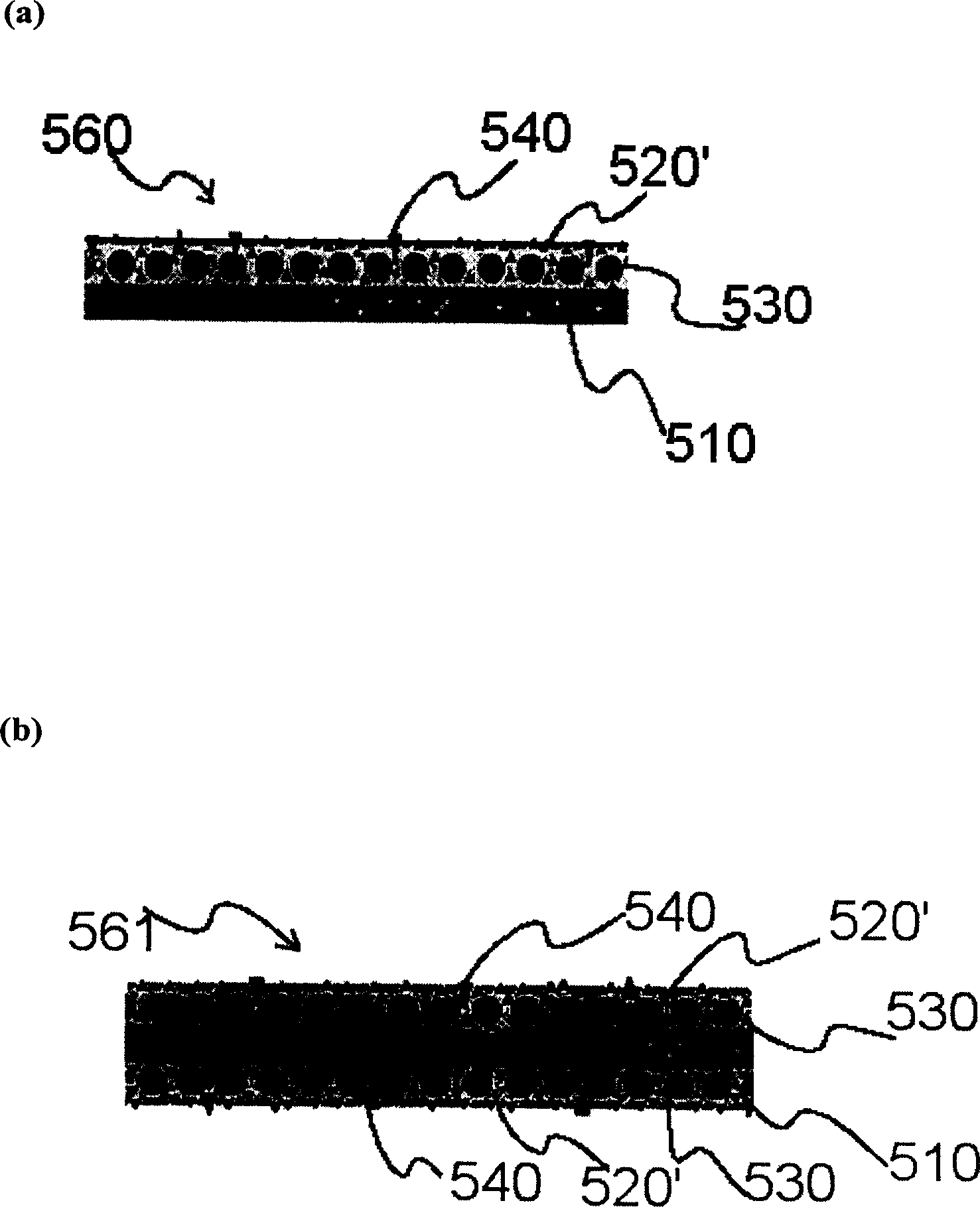

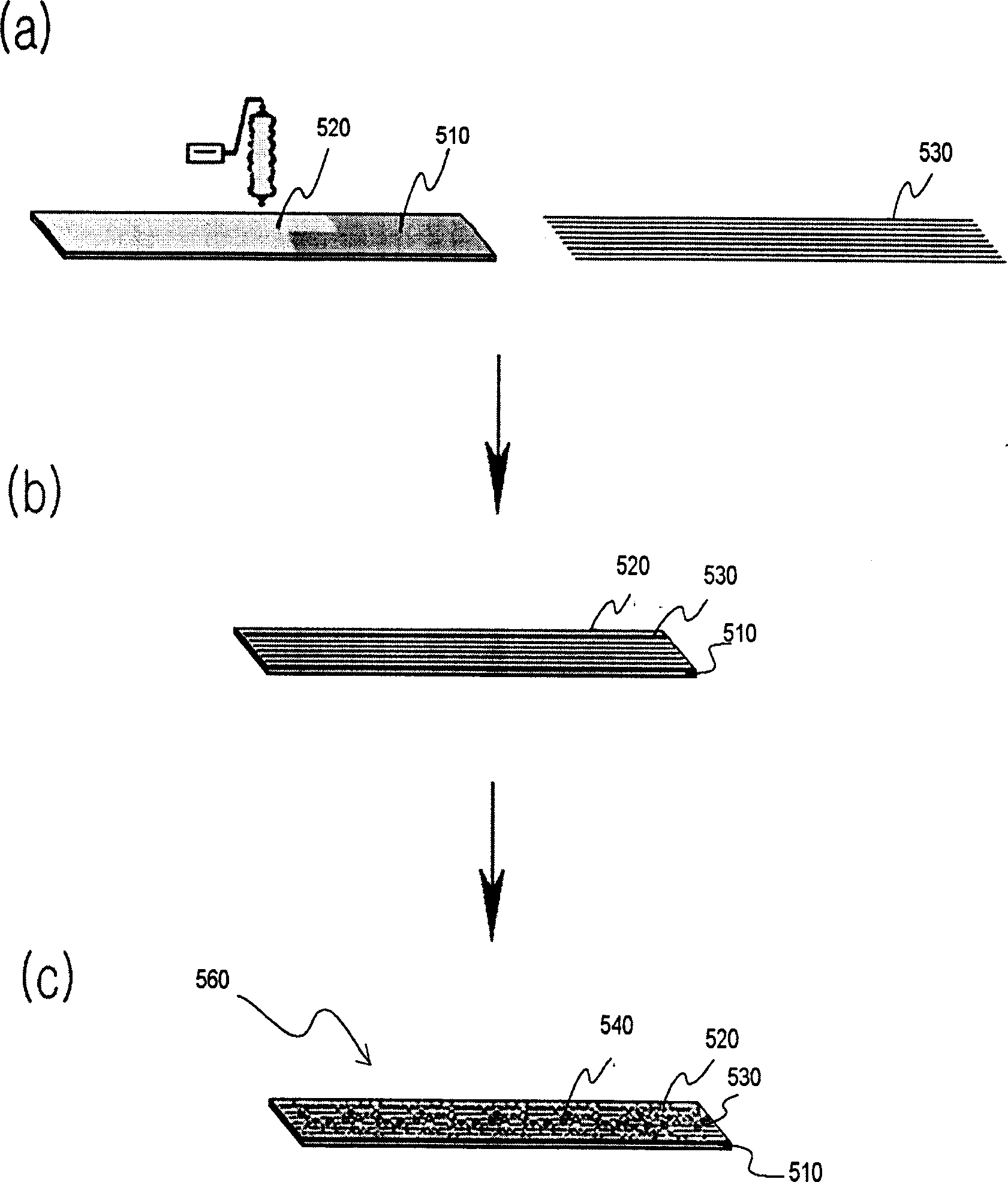

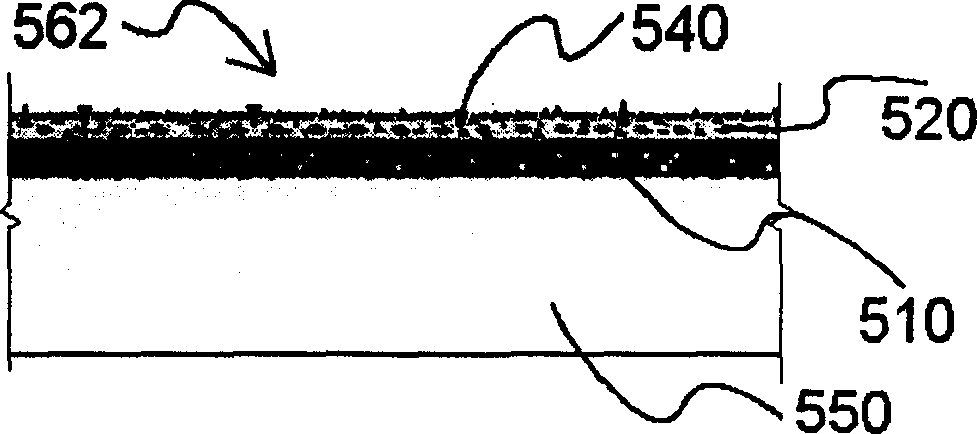

[0038] figure 1 is a sectional view showing an embodiment of a composite panel for reinforcing a concrete body according to the present invention, and figure 2 yes means figure 1 Flowchart of the fabrication method of the composite panel. exist figure 1 and 2 Among them, the composite plate used to strengthen the concrete body includes: a steel plate 510 of a specified size; an impregnable bonding layer 520' formed on the upper surface of the steel plate 510; The impregnated bonding layer 520' penetrates and bonds the reinforcing fibers 530; and the powder 540 is sprayed onto the upper surface of the steel plate 510 and is impregnated and bonded on the impregnable bonding layer 520'. In addition, the manufacturing method of the composite plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com