Positive electrode active material, positive electrode plate and lithium ion secondary battery

A positive electrode active material, positive electrode sheet technology, applied in secondary batteries, active material electrodes, positive electrodes, etc., can solve the problems of poor high temperature cycle performance of lithium ion secondary batteries, and achieve improved structural stability and high temperature cycle stability. properties, improved deformation resistance, high charge-discharge voltage and specific capacity characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] Next, a method for preparing a cathode active material is schematically illustrated. According to the preparation method, any one of the positive electrode active materials mentioned above can be prepared. Preparation methods include:

[0078] The positive electrode active material precursor, the lithium source and the dopant element precursor are mixed and sintered to obtain the positive electrode active material.

[0079] The above-mentioned positive electrode active material precursor can be one or more of oxides, hydroxides and carbonates containing Ni and optionally Co and / or Mn according to the stoichiometric ratio, for example, containing Ni according to the stoichiometric ratio. Hydroxide of Ni, Co and Mn.

[0080] The positive electrode active material precursor can be obtained by methods known in the art, for example, prepared by co-precipitation method, gel method or solid phase method.

[0081] As an example, the Ni source, the Co source and the Mn source...

Embodiment 1

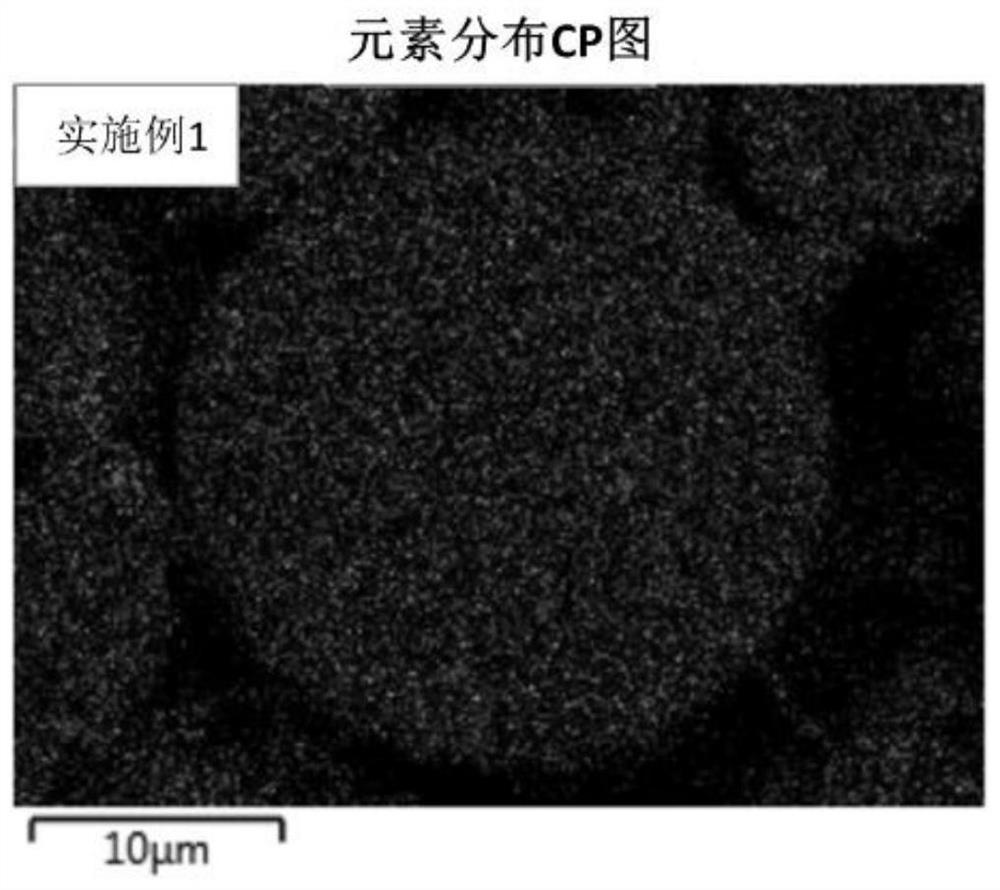

[0123] Preparation of cathode active material

[0124] The doping element is Sb, and the precursor of the doping element is antimony oxide (Sb 2 o 3 ) roughly equally divided into 3 batches for Sb doping. Preparation methods include:

[0125] The cathode active material precursor [Ni 0.8 co 0.1 mn 0.1 ](OH) 2 , Lithium hydroxide LiOH and the first batch of antimony oxide are added in a high-speed mixer and mixed for 1h to obtain a mixed material, wherein the molar ratio Li / Me of the positive electrode active material precursor to lithium hydroxide is 1.05, and Me represents The total molar amount of Ni, Co, and Mn in the positive active material precursor; put the mixed material into the atmosphere sintering furnace for the first sintering, the sintering temperature is 830°C, the sintering time is 5h, and the sintering atmosphere is O 2 An atmosphere containing oxygen at a concentration of 90%.

[0126] The product of the first sintering treatment and the second batc...

Embodiment 2~13 and Embodiment 16~24

[0139] The difference from Example 1 is that the relevant parameters in the preparation steps of the positive electrode active material are changed, the oxide of the doping element is selected as its source, and the content of each batch when the doping element is mixed, and the sintering temperature is 800 ° C ~ 850 ° C, the total The sintering time is 15h-25h, and the positive electrode active material with predetermined doping element type, doping amount and doping uniformity is obtained, see Table 1 and Table 2 for details.

[0140] In Example 4 and Example 12 involving multi-element doping, the content of each doping element is basically the same.

[0141] And the positive electrode active material precursor in the embodiment 22~24 is [Ni 0.5 co 0.2 mn 0.3 ](OH) 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com