Method for producing flat filaments from polyester chips

A technology of polyester chips and flat yarns, applied in the direction of single-component polyester rayon, melt spinning, stretch spinning, etc., can solve the problem that the woven bag is difficult to meet the tensile properties, and prevent embrittlement Fracture, reduced crystallization, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

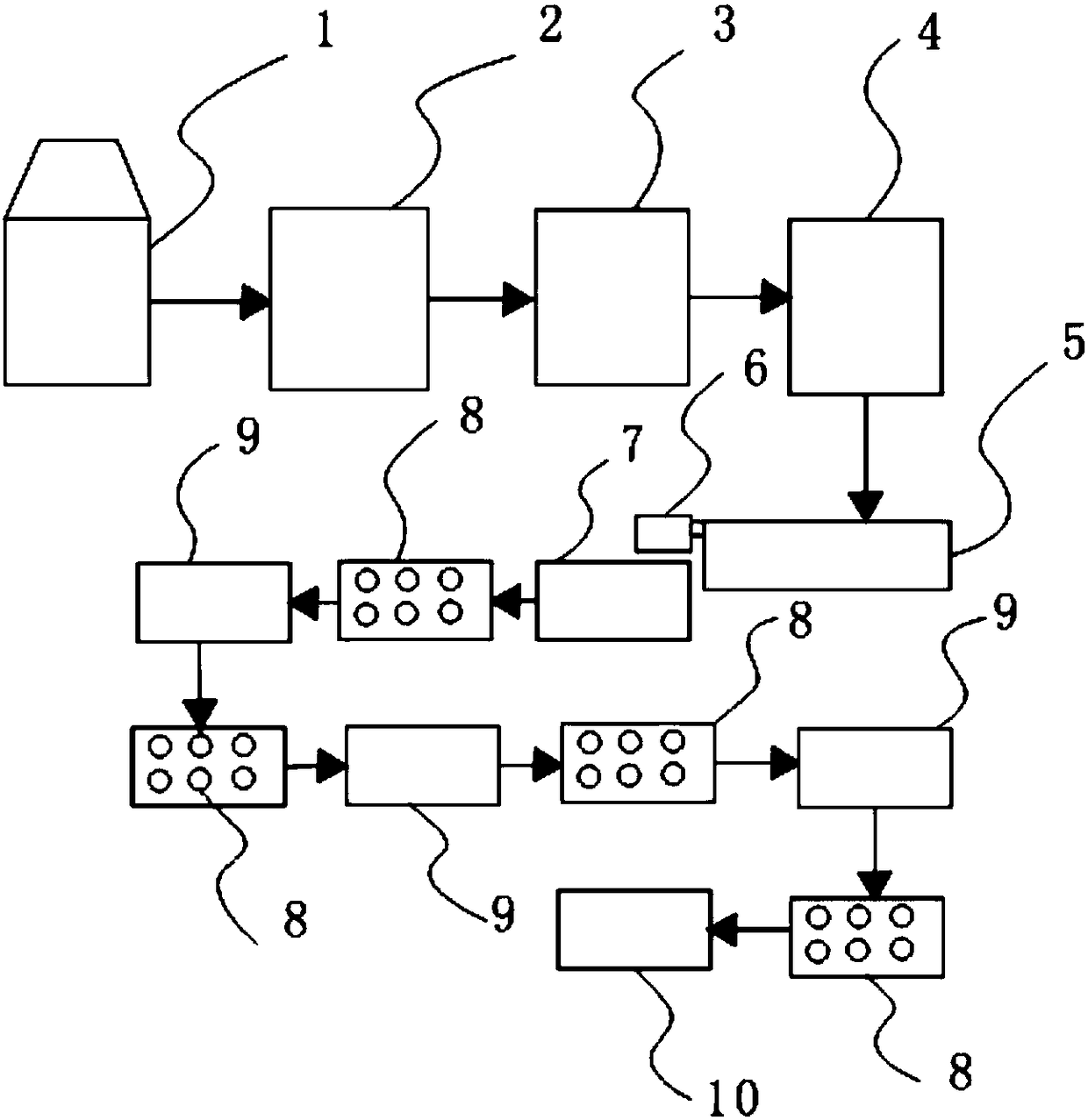

[0022] Step 1: put a certain weight of polyester chip raw material, 0.5% polyester chip weight anti-aging agent and 1‰ polyester chip color masterbatch into the mixer 1, mix well and then enter the pre-crystallizer 2 Crystallization treatment, and then enter the dehumidification dryer 3 for dehumidification and drying processing to become a uniform state, and then enter the screw extruder 5 through the adsorber 4;

[0023] The second step: in the screw extruder, under the temperature condition of 250-330 ℃, the dried slices are melt-blended and then extruded;

[0024] The third step: the molten material extruded by the screw extruder enters the spinneret die device 6 and is directly obtained after being sprayed out through the nozzle hole of the spinneret. The width is 3mm-12mm, the thickness is 0.05mm-1mm, and the draw ratio is 1.5-10 initial flat wire;

[0025] Step 4: Enter the initial flat yarn obtained in the third step into the water circulation cooling device 7 for coo...

specific Embodiment 2

[0030] Step 1: Put a certain weight of polyester slice raw material, 3% polyester slice weight anti-aging agent and 3‰ polyester slice weight masterbatch into the mixer, mix and stir evenly, enter the pre-crystallizer for crystallization treatment , and then enter the dehumidification dryer for dehumidification and drying processing to become a uniform state, and then enter the screw extruder through the adsorber; then repeat the second step to the eighth step of the specific embodiment one, and finally obtain a width of 1.5-3mm and a thickness of 0.05 -0.25mm, the draw ratio is 1.5-8, the monofilament tensile strength is 150-350N, and the elongation is less than 30% finished flat yarn;

specific Embodiment 3

[0031] Step 1: Put a certain weight of polyester chip raw material, 1.5% polyester chip weight anti-aging agent and 2‰ polyester chip color masterbatch into the mixer, mix and stir evenly, enter the pre-crystallizer for crystallization treatment , and then enter the dehumidification dryer for dehumidification and drying processing to become a uniform state, and then enter the screw extruder through the adsorber; then repeat the second step to the eighth step of the specific embodiment one, and finally obtain a width of 1.5-3mm and a thickness of 0.05 -0.25mm, draw ratio of 1.5-8, monofilament tensile strength of 150-350N, elongation less than 30% finished flat yarn.

[0032] In the present invention, polyester chips are added with appropriate anti-aging agent and color masterbatch, mixed and stirred, crystallized, dried, extruded by an extruder, and then entered into a spinning die device for spinning to obtain the initial flat filament directly, without cutting by a cutting de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretch ratio | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com