Cold rolling method for high grade non-oriented silicon steel through hot rolling, acid pickling and non-edge-cutting

A technology of oriented silicon steel, hot rolling and pickling, applied in the field of silicon steel cold rolling, can solve the problems of low rolling efficiency and low yield of high silicon content varieties, achieve good surface quality, improve yield, and high product shape quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

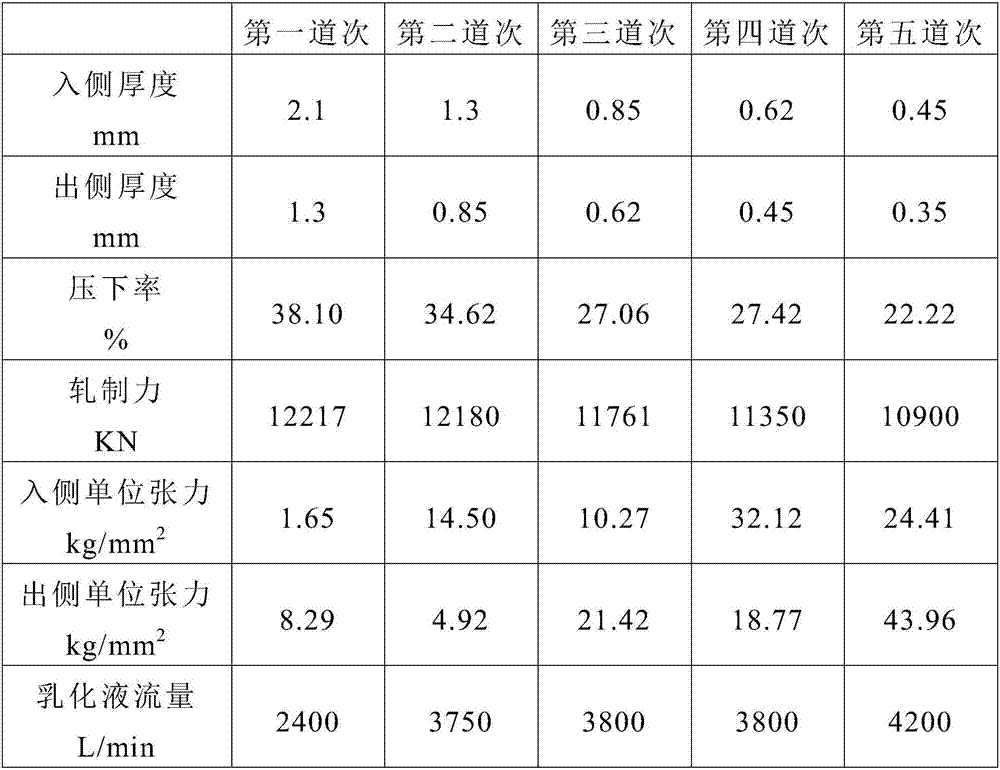

[0026] Using CVC six-high reversing mill to produce 3.01% Si, 1210mm plate width non-oriented high-grade silicon steel hot-rolled pickled coil without trimming, includes the following steps:

[0027] A) The steel coil is obtained by smelting, continuous casting and hot rolling using conventional non-oriented high-grade technology. The thickness of the steel coil before cold rolling is 2.1mm. The steel coil is subjected to normal pickling without trimming;

[0028] B) Using the one-time cold rolling method, the steel coil obtained in step A) is continuously and reversibly cold-rolled in five passes. The five passes are all rolled by a pair of work rolls. The work rolls are all flat rolls and the roll diameter is 300mm, the surface roughness of the work roll is 0.3μm, and the reduction rate, rolling force, unit tension of the inlet side and unit tension of the outlet side of each pass are controlled. For specific data, see Table 1. The rolling is carried out by emulsion spray Process...

Embodiment 2

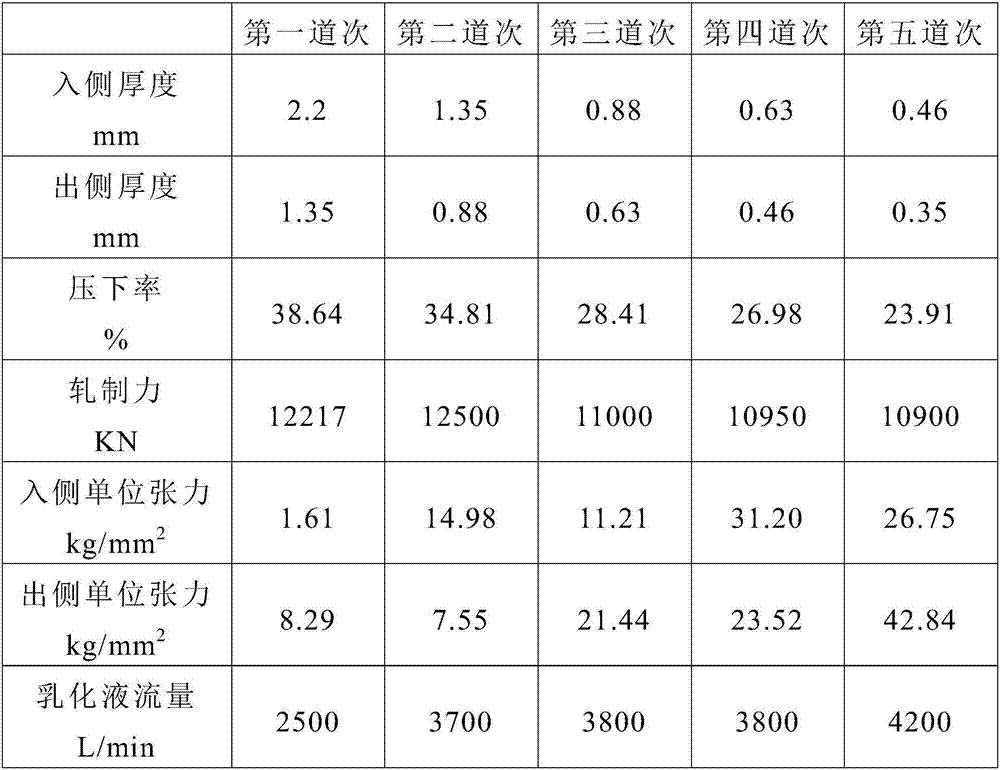

[0036] Using a CVC six-high reversing mill to produce 3.02% Si and a plate width of 1170mm non-oriented high-grade silicon steel hot-rolled pickled and non-trimmed coils, including the following steps:

[0037] A) The steel coil is obtained by smelting, continuous casting and hot rolling using conventional non-oriented high-grade technology. The thickness of the steel coil before cold rolling is 2.2mm, and the steel coil is subjected to normal pickling without trimming;

[0038] B) Using the one-time cold rolling method, the steel coil obtained in step A) is continuously and reversibly cold-rolled in five passes. The five passes are all rolled by a pair of work rolls. The work rolls are all flat rolls and the roll diameter is 320mm, the surface roughness of the work roll is 0.5μm, and the reduction rate, rolling force, unit tension on the inlet side and unit tension on the outlet side of each pass are controlled. See Table 2 for specific data. The rolling is carried out by emulsion ...

Embodiment 3

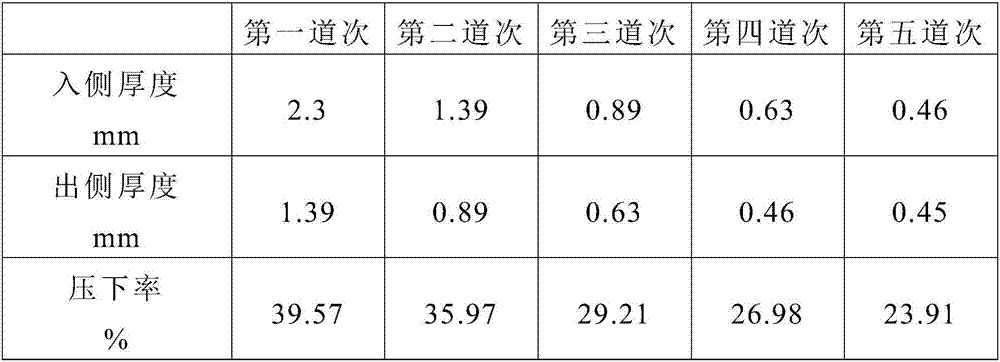

[0046] Using a CVC six-high reversing mill to produce 3.01% Si, a plate width of 1150mm non-oriented high-grade silicon steel hot-rolled pickled and non-trimmed coils, including the following steps:

[0047] A) The steel coil is obtained by smelting, continuous casting and hot rolling using conventional non-oriented high-grade technology. The thickness of the steel coil before cold rolling is 2.3mm, and the steel coil is subjected to normal pickling without trimming;

[0048] B) Using the one-time cold rolling method, the steel coil obtained in step A) is continuously and reversibly cold-rolled in five passes. The five passes are all rolled by a pair of work rolls. The work rolls are all flat rolls and the roll diameter is 310mm, the surface roughness of the work roll is 0.4μm, and the reduction rate, rolling force, unit tension on the inlet side and unit tension on the outlet side of each pass are controlled. See Table 3 for specific data. The rolling is carried out by emulsion spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com