Guiding mechanism

A technology of guiding mechanism and telescopic mechanism, which is applied in the field of machine tools, can solve problems such as winding and deviation, tool broken belt, etc., and achieve the effect of reducing the risk of broken belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

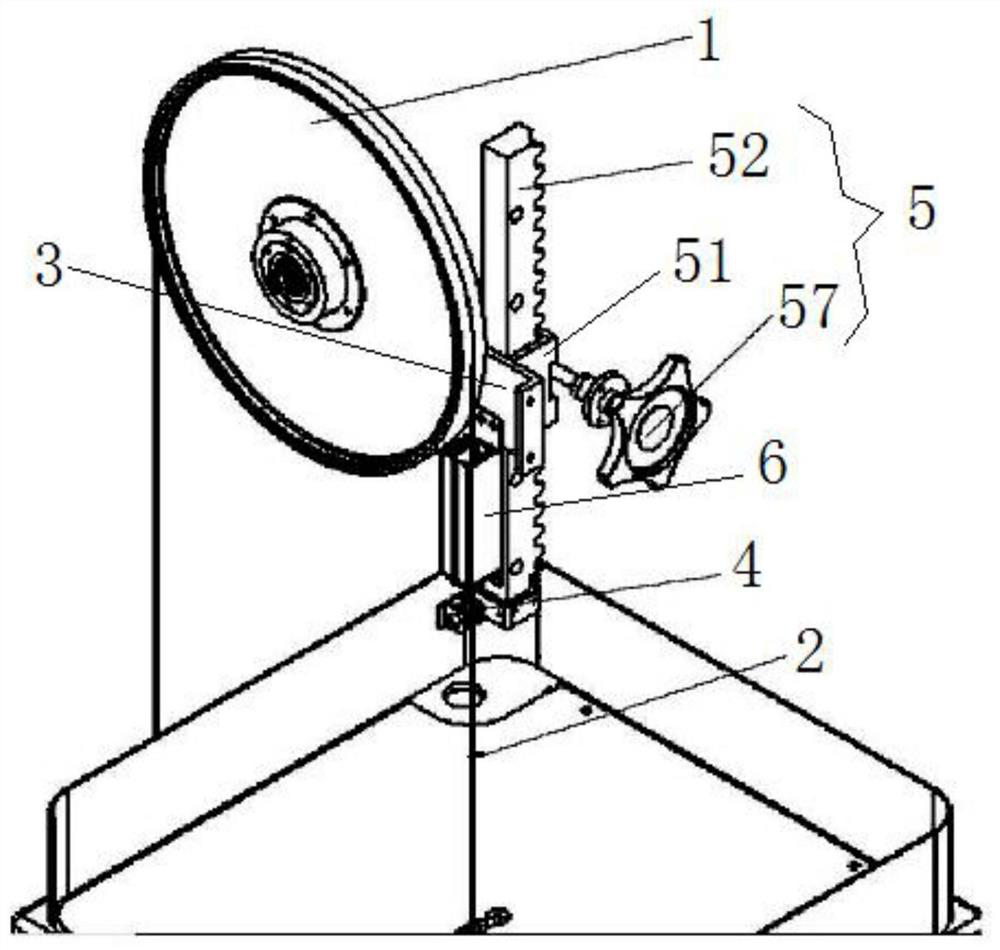

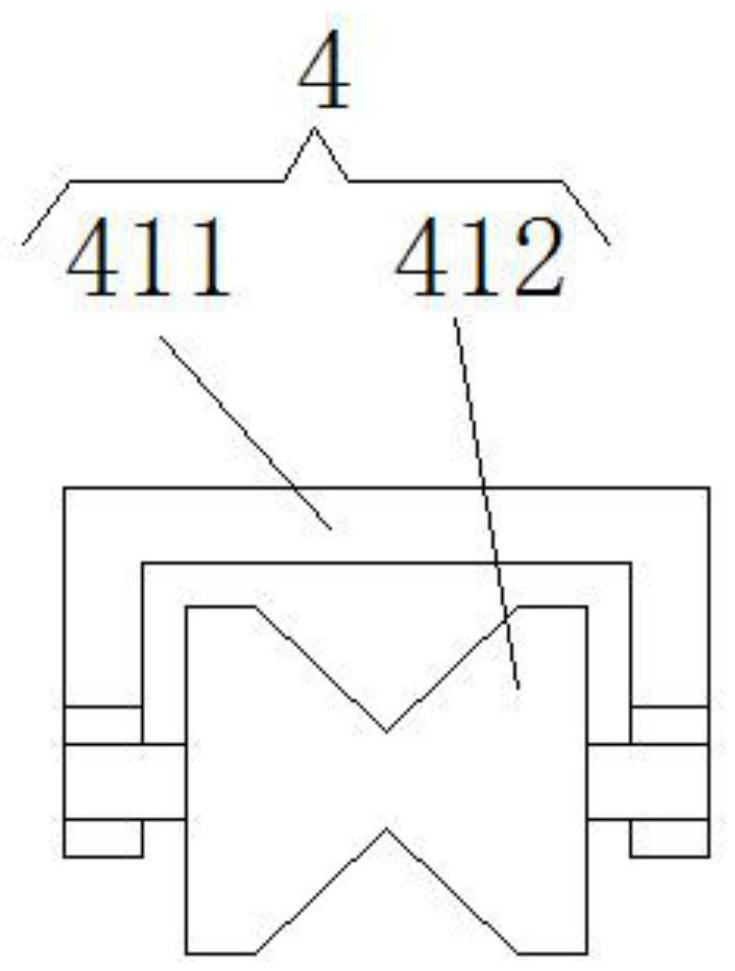

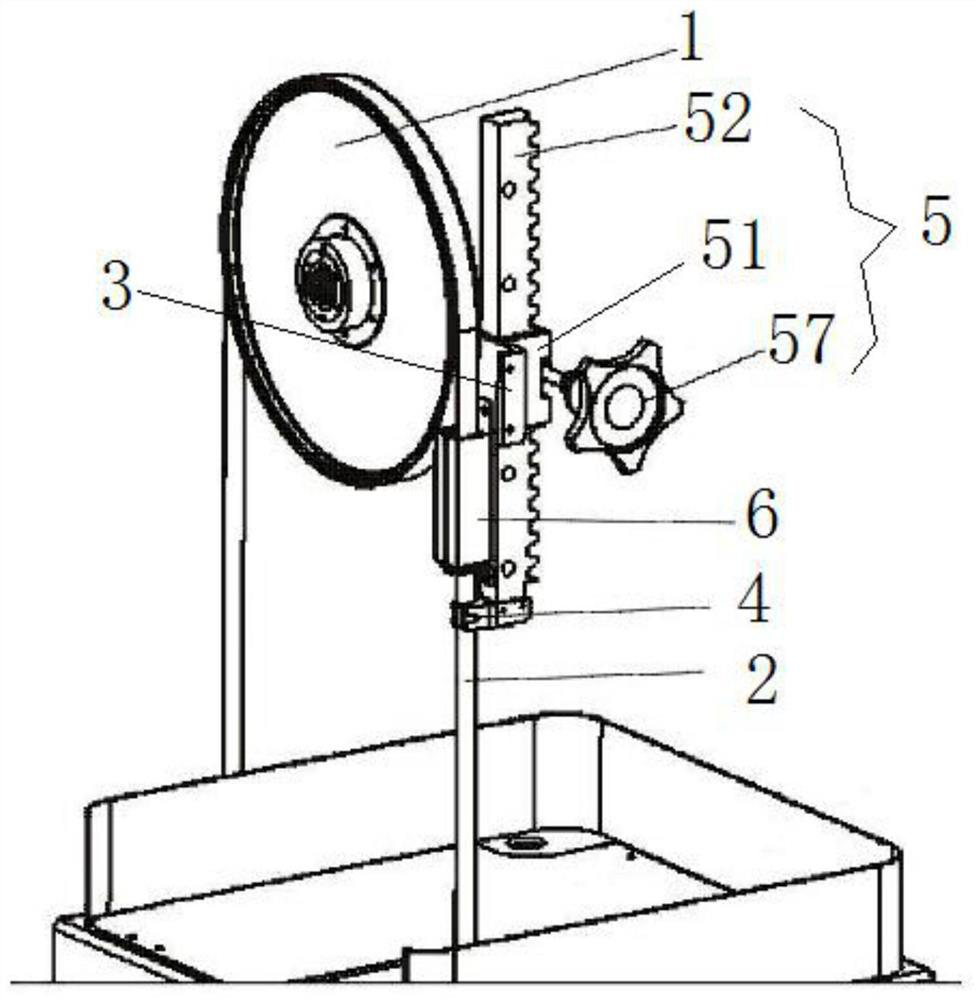

[0026] Such as Figure 1-9 As shown, the guide mechanism, the guide mechanism is installed on the sawing machine, a pair of runners 1 are arranged on the sawing machine, and a tool belt 2 is tightened on the pair of runners 1, and the guide mechanism includes one end fixed on the frame The mounting plate 3 on the top, the mounting plate 3 is arranged parallel to the runner 1, and the other end of the mounting plate 3 extends to the side of the tool belt 2 driven by the runner 1, and the vertical direction is installed on the mounting plate 3 The bottom end of the telescopic mechanism 5 in the vertical direction is a moving end, and the bottom end of the telescopic mechanism 5 in the vertical direction is fixedly connected with a guide unit 4 that cooperates with the tool belt 2 . The guide mechanism proposed by the technical solution can reduce the vibration frequency and amplitude of the part of the tool belt not in contact with the runner by setting the guide unit, thereby r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com