Motor with damping function

A motor and functional technology, applied in the field of motors, can solve the problems of motor rotation resistance and noise increase, mounting seat lateral vibration, corrosion and damage of components, etc., and achieve the effect of reducing shear stress increase, scientific and reasonable structure, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

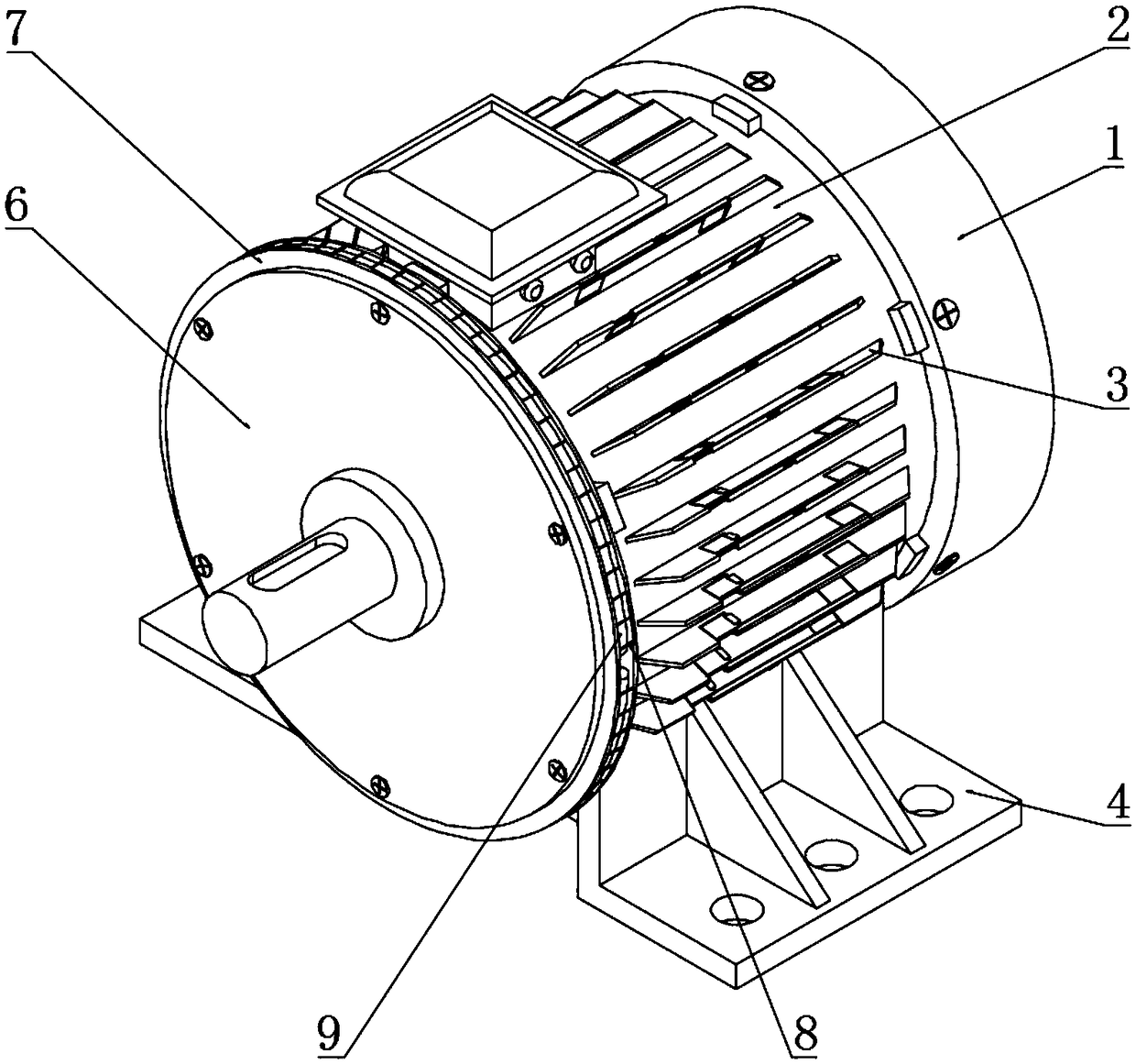

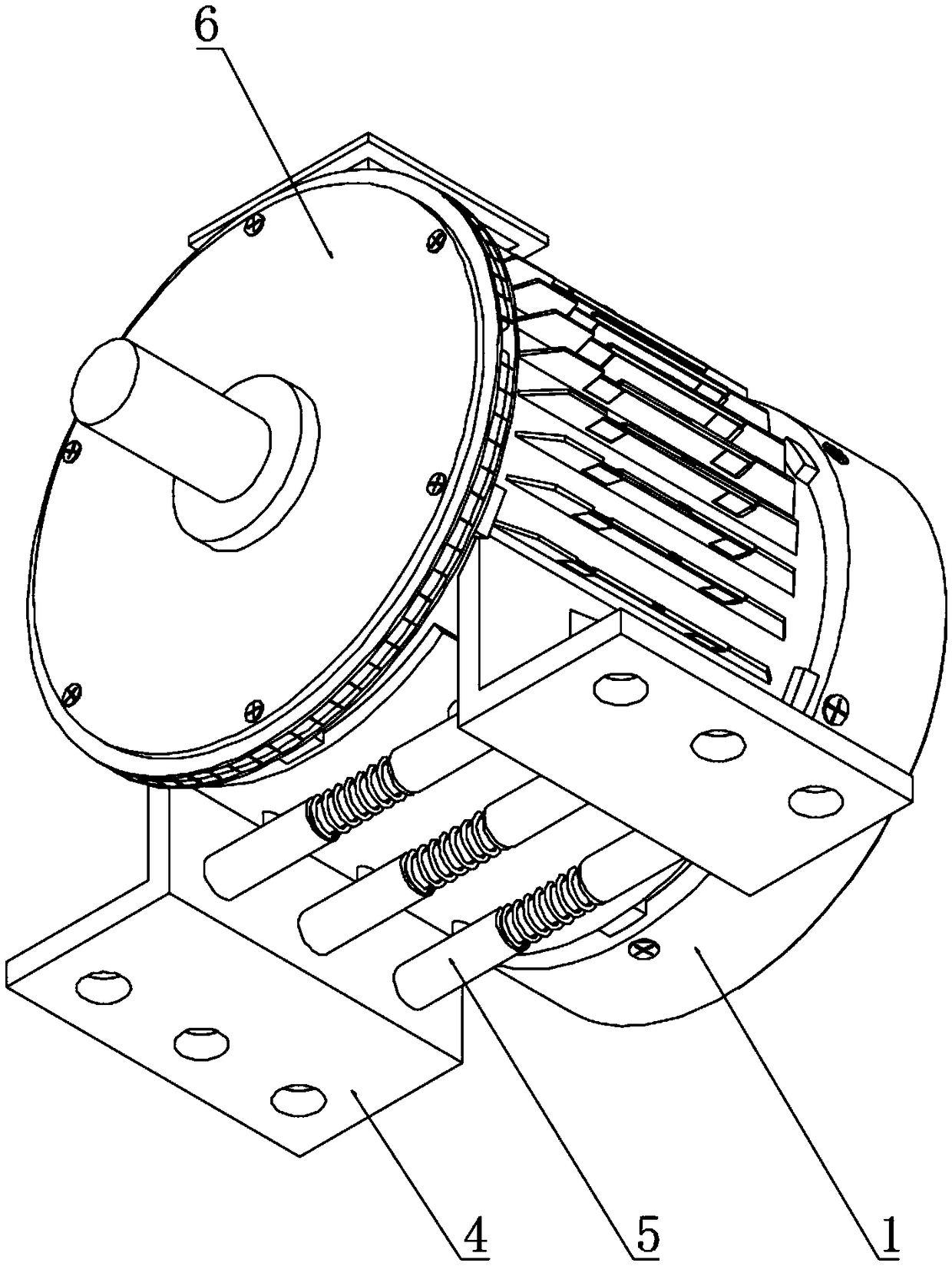

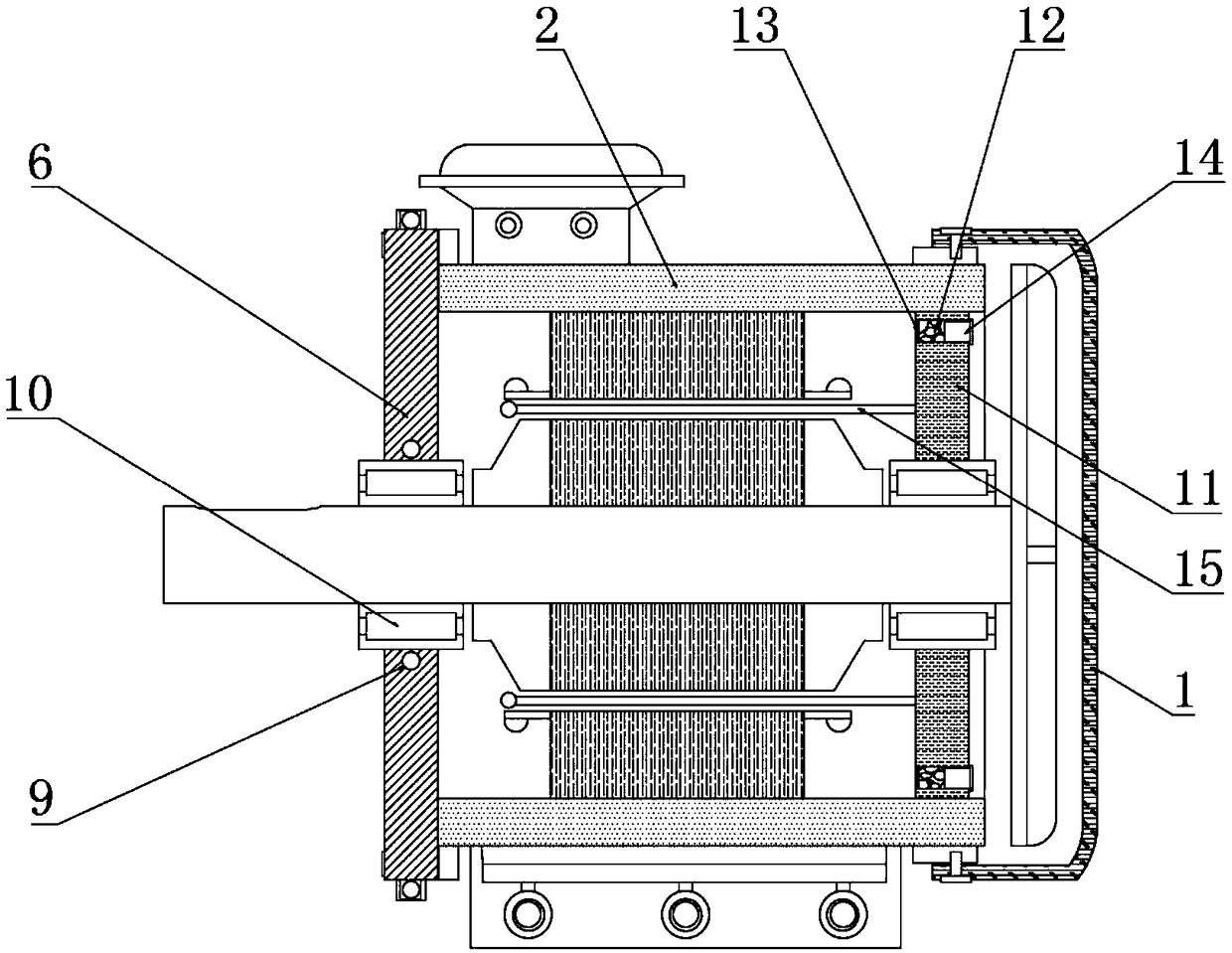

[0031] Example: such as Figure 1-8As shown, the present invention provides a technical solution, a motor with a shock absorbing function, including a motor body 1, a fuselage 2 is arranged in the middle of the motor body 1, a heat dissipation mechanism 3 is uniformly installed on the outer surface of the fuselage 2, and the heat dissipation mechanism 3 Including heat sink 301, installation groove 302, limit baffle 303, baffle plate 304, chute 305, fixing hole 306 and adjustment assembly 307, heat sink 301 has installation groove 302 symmetrically on both sides, and installation groove 302 is installed on one side Limit baffle 303, the number of limit baffle 303 is set to two, and baffle plate 304 is installed through rotating shaft inside installation groove 302, in order to ensure that limit baffle 303 can block baffle plate 304, make baffle plate 304 to To move in different directions, the top of the deflector 304 is provided with a chute 305, and the two sides of the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com