Welding line stretching and bending experimental instrument

An experimental instrument and tensile bending technology, which can be used in instruments, scientific instruments, measuring devices, etc., can solve the problems of broken belts in welds and failure of test results to meet the requirements of production practice, so as to improve reliability and reduce weld fractures. risky effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to understand the present invention in depth, the present invention will be described in detail below with reference to the drawings and specific embodiments.

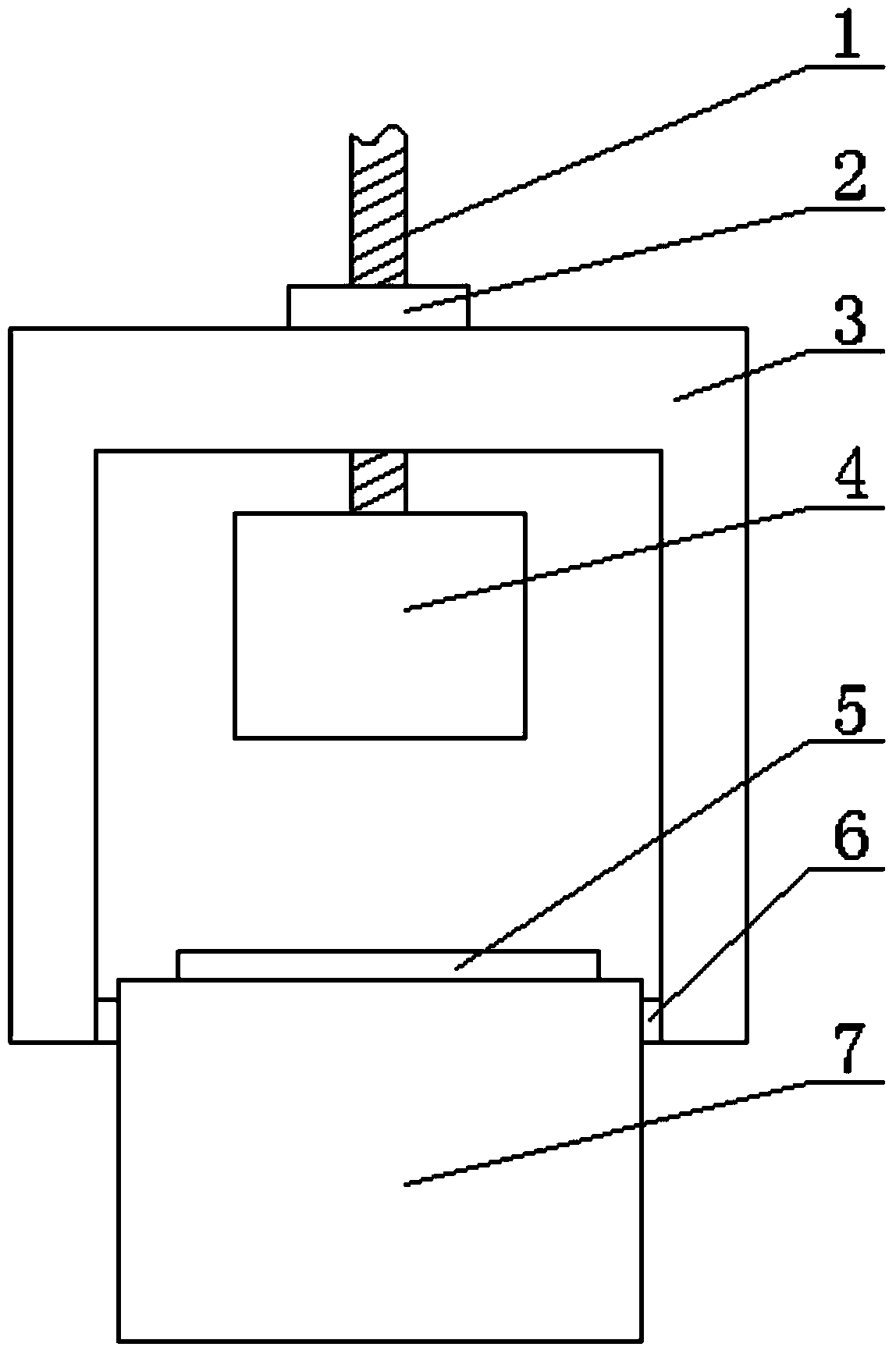

[0024] See attached figure 1 , The present invention provides a welding seam stretching and bending tester, including: upper clamp 4 and lower clamp 7 for clamping the weld test piece, swing arm 3 and vertical adjustment of upper clamp 4 Position adjustment assembly; the lower clamp 7 is movably connected with the swing arm 3; the swing arm 3 is placed above the lower clamp 7 and can be turned relative to the lower clamp 7; the upper clamp 4 is set on the swing arm 3 through the adjustment assembly; The adjustment and adjustment assembly can make the upper clamp 4 move vertically relative to the swing arm 3. The lower clamp 7 clamps one end of the weld specimen to ensure that the position of the weld specimen will not change during the bending and stretching process. The upper clamp 4 clamps the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com