Aging-resistant tinplated substrate and manufacturing method thereof

A technology of a tin-plated substrate and a manufacturing method, which is applied to the field of aging-resistant tin-plated substrate and its manufacturing, and can solve the problems of low aging-resistance performance and poor surface quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

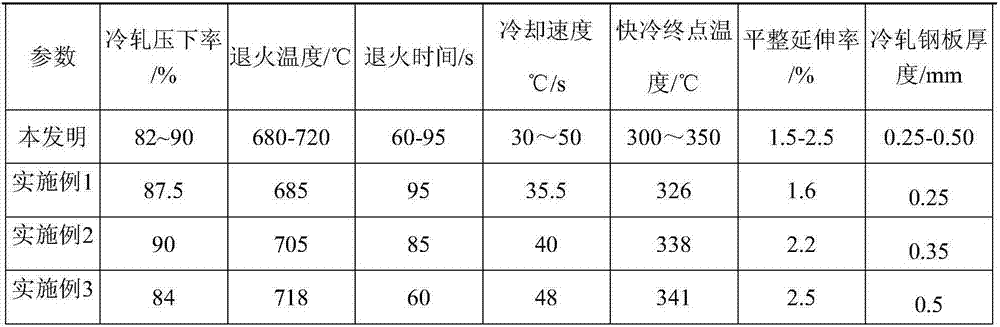

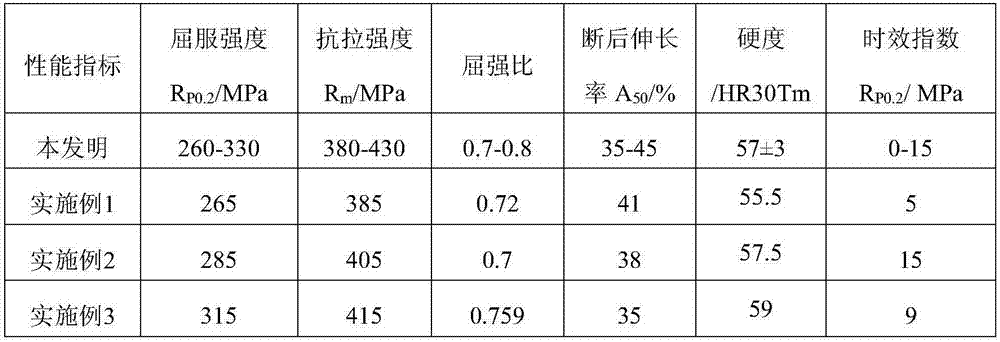

[0045] The present invention will be further described below in conjunction with Embodiments 1-3.

[0046] Table 1 is the chemical composition (by weight percentage) of the steel of the embodiment of the present invention, and the balance is iron and unavoidable impurities.

[0047] Table 1 Chemical composition of the steel of the embodiment of the present invention, unit: weight percent.

[0048] element

C

Si

mn

P

S

Alt

N

Ti

this invention

≤0.005

≤0.04

0.3-0.5

0.05-0.08

≤0.02

0.01-0.06

≤0.005

0.04-0.08

Example 1

0.0026

0.025

0.42

0.074

0.01

0.03

0.0035

0.046

Example 2

0.0015

0.028

0.33

0.066

0.012

0.035

0.0042

0.06

Example 3

0.004

0.03

0.45

0.053

0.016

0.053

0.0025

0.055

[0049] The molten steel with the required chemical composition is obtained through converter smelting, and the molten steel is vacuum degassed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com