Anode plate, secondary battery thereof and preparation method

A technology of positive electrode sheet and positive electrode current collector, which is applied in the field of secondary batteries, and can solve the problems of increasing manufacturing costs, reducing the service life of cold pressure rollers, and increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

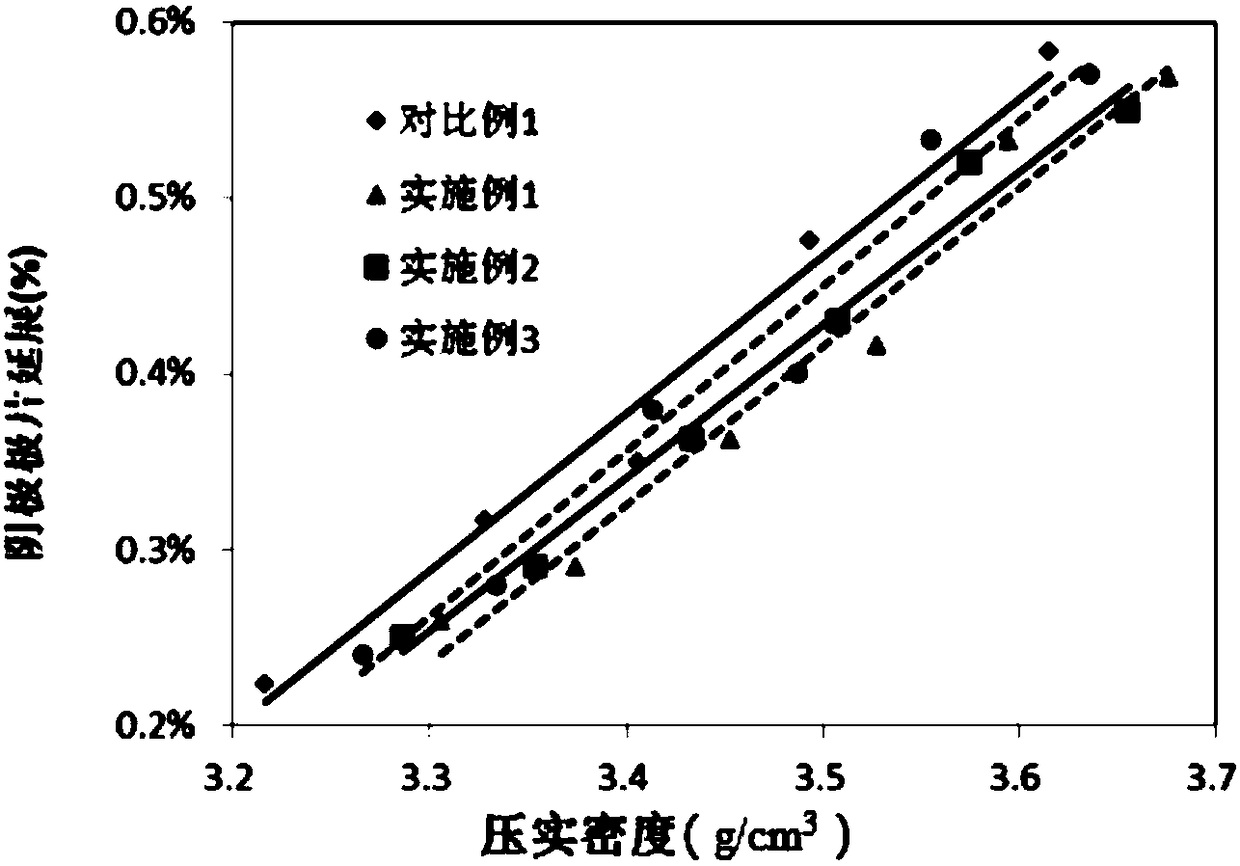

Examples

preparation example Construction

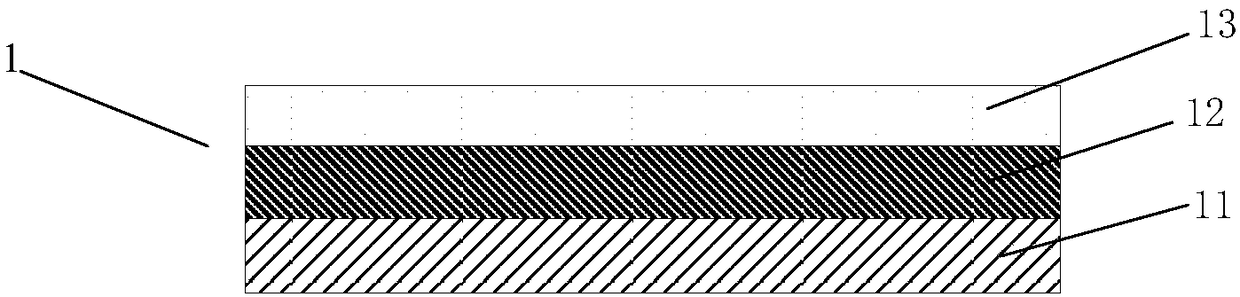

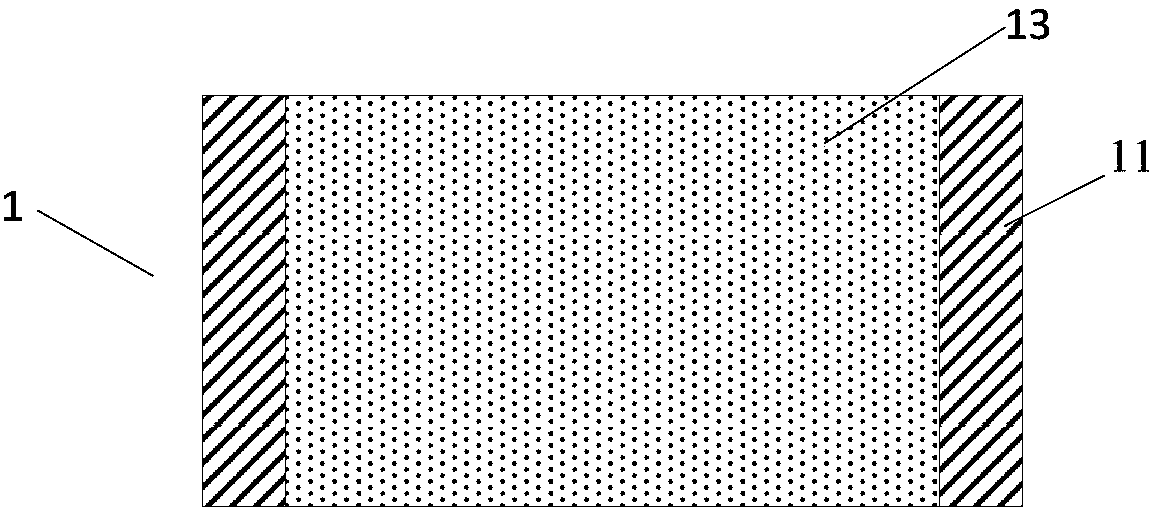

[0067] As the preparation method of the positive electrode sheet of the third aspect of the embodiment of the present application, at least the following steps are included:

[0068] Step 1, preparing the positive electrode active material layer on the positive electrode current collector;

[0069] Step 2, mixing the material of the lubricating coating with an organic solvent to prepare a solution;

[0070] Step 3, using a solution to prepare a lubricating coating on the positive electrode active material layer, and then performing cold pressing on the positive electrode sheet prepared with the lubricating coating; or

[0071] The solution is used to prepare a lubricating coating on the positive electrode active material layer, and at the same time, cold pressing is carried out on the positive electrode sheet prepared with the lubricating coating.

[0072] Further optionally, the solution containing the above-mentioned modified silicone oil is coated on both sides of the posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com