Oriented silicon steel annealing sleeve and oriented silicon steel annealing method

A technology of oriented silicon steel and sleeves, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of uneven heating of oriented silicon steel, achieve low cost, simple manufacture, and improve uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

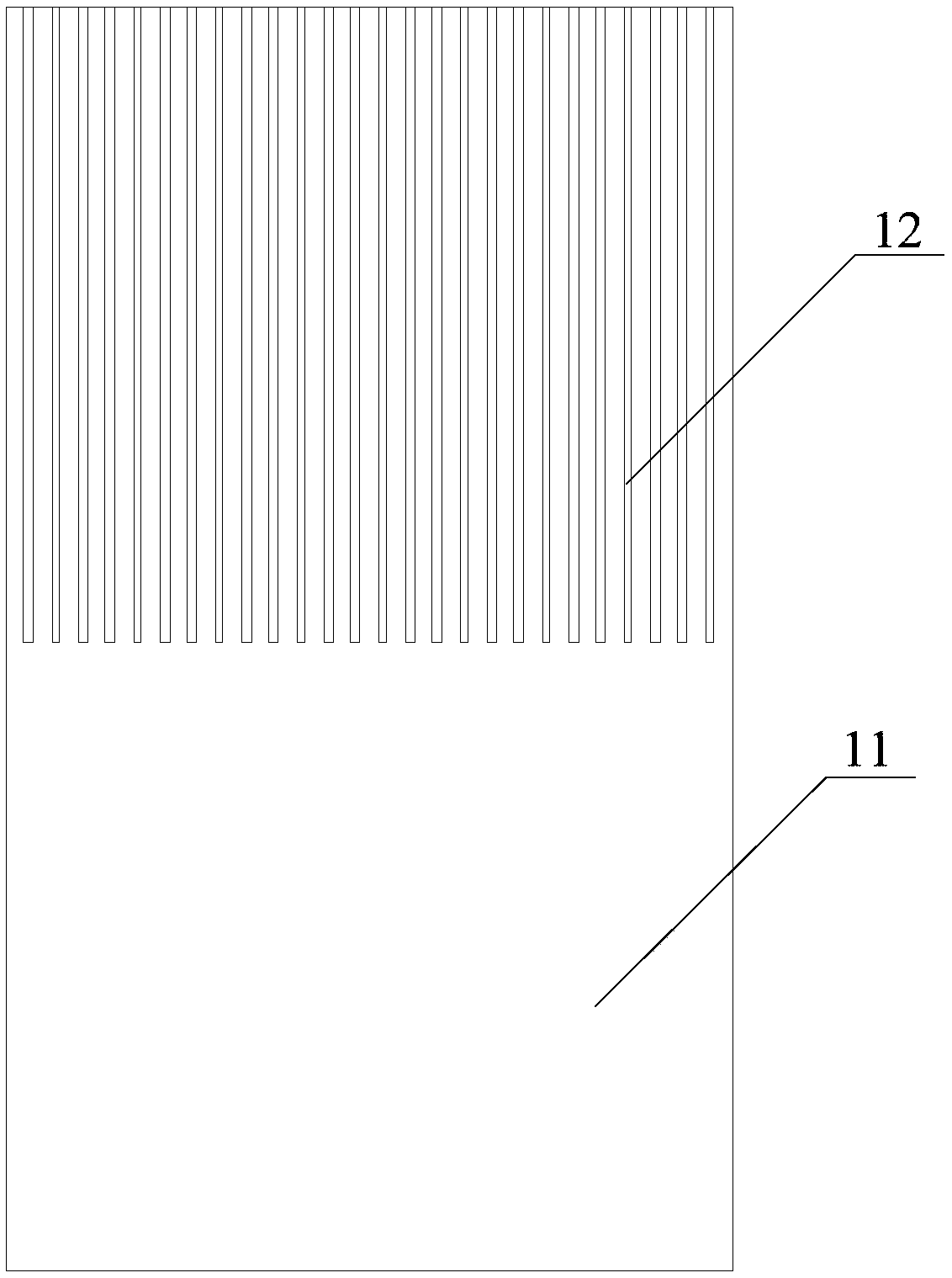

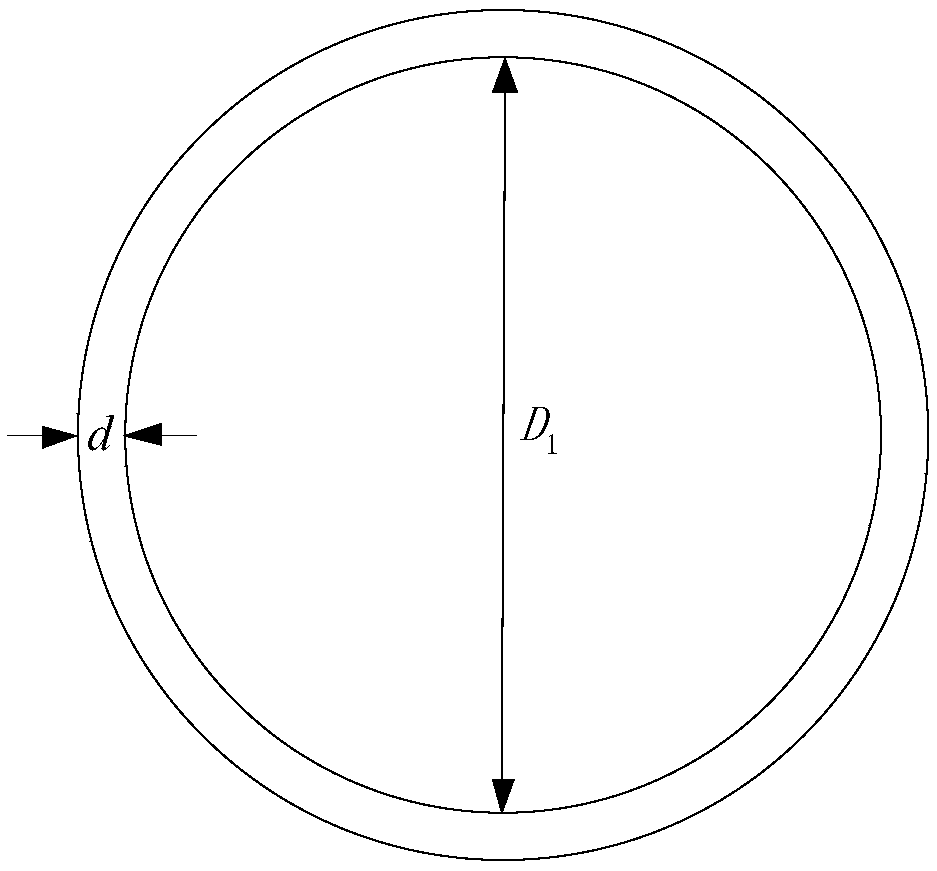

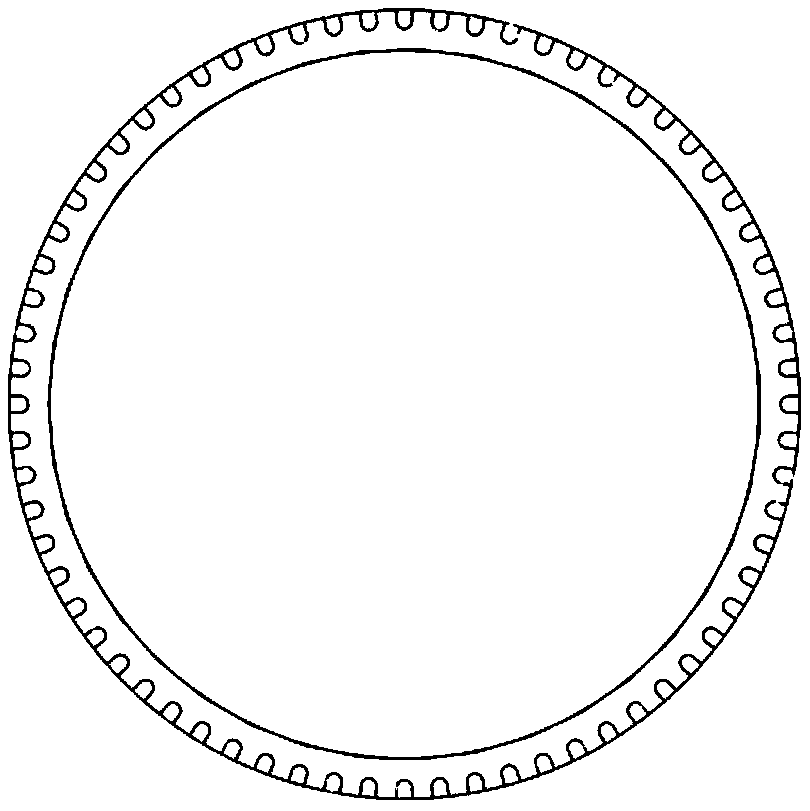

[0037] This embodiment provides a sleeve for annealing oriented silicon steel, figure 1 is the front view of the annealing sleeve for grain-oriented silicon steel, figure 2 is the bottom view of the sleeve for annealing oriented silicon steel, image 3 is a top view of the sleeve for annealing oriented silicon steel, Figure 4 yes image 3 A partial enlargement of the . refer to Figure 1 to Figure 4 , the annealing sleeve for oriented silicon steel includes a sleeve body 11 and at least two grooves 12 arranged on the outer wall of the sleeve body 11 .

[0038] Specifically, the sleeve body 11 is tubular. In this embodiment, the horizontal section of the inner wall of the sleeve body 11 is circular. In other embodiments, the horizontal section of the inner wall of the sleeve body 11 may also be in geometric shapes such as square, rhombus, and triangle, which is not limited in the present invention. The length of the sleeve body 11 can be determined according to the wid...

Embodiment 2

[0043] This embodiment provides another sleeve for annealing oriented silicon steel, Figure 5 It is the front view of the sleeve for annealing oriented silicon steel, and the bottom view, top view and partial enlarged view of the sleeve for annealing oriented silicon steel can refer to Example 1. Compared with Embodiment 1, the difference of this embodiment is that the number of the grooves 12 is at least four, and the at least four grooves 12 include at least two first grooves 121 and at least two second grooves. groove 122 , and the length of the first groove 121 is smaller than the length of the second groove 122 . In this embodiment, the length of the first groove 121 is The length of the second groove 122 is Among them, l 0 is the length of the sleeve body 11. The depth of the first groove 121 and the depth of the second groove 122 may be the same or different.

[0044] Further, the first groove 121 and the second groove 122 are arranged at intervals, that is, the...

Embodiment 3

[0051] This embodiment provides a method for annealing grain-oriented silicon steel, including:

[0052] The annealing sleeve for oriented silicon steel is used as the inner core to coil the oriented silicon steel to obtain a steel coil, and the annealing sleeve for oriented silicon steel can be the sleeve for annealing oriented silicon steel provided in embodiment 1 or embodiment 2;

[0053] Rolling the steel into a furnace for high-temperature annealing, during which the upper end of the sleeve body 11 faces upward;

[0054] After the high-temperature annealing is completed, the steel coil is sent to the stretching and tempering unit for uncoiling, so as to remove the annealing sleeve for the oriented silicon steel.

[0055] It can be seen that the sleeve for annealing oriented silicon steel is easy to operate and can be recycled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com