Lithium ion battery positive pole piece and gap coating method thereof

A technology of lithium ion battery and positive pole piece, applied in battery electrodes, non-aqueous electrolyte battery electrodes, electrode manufacturing, etc., can solve problems such as pole fragmentation, improve thickness uniformity, improve cold-pressed stripping, and reduce stress cumulative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

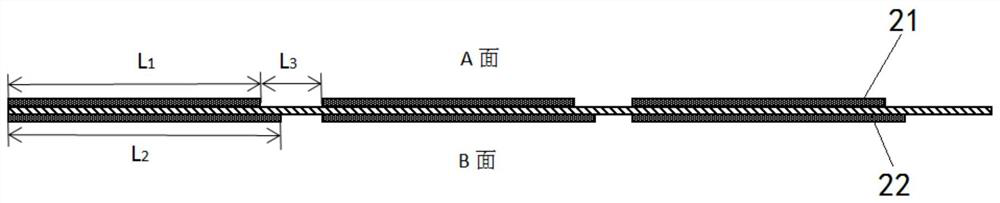

[0032] A method for gap coating of the positive electrode sheet of a lithium ion battery. First, the positive electrode slurry is coated on the surface A of the aluminum foil 1 according to the normal coating process, and the ceramic slurry is continuously coated, and then dried and wound after coating. , to form a single-sided pole piece; then take the above-mentioned single-sided pole piece to the coating machine head, perform gap coating on the B side, and then dry to obtain the positive pole piece.

[0033] Specifically, the positive electrode slurry coating gap L on the aluminum foil 1 3 40mm~60mm, the ceramic slurry is continuously coated on the edge of the positive electrode slurry, the coating position of the first segment of the positive electrode slurry on the A side is aligned with the coating position of the first segment of the B side, and the coating position of the tail segment of the positive electrode slurry on the A side is aligned with the coating position of...

Embodiment 2

[0035] A method for coating gaps between positive pole pieces of a lithium-ion battery, the specific steps of which are as follows:

[0036] S1: Gap coating 1: Put the empty aluminum foil 1 at the coating head, the die head of the coating machine uses positive electrode slurry and ceramic slurry, firstly coat the A side of the aluminum foil 1, and the positive electrode slurry when coating Gap coating according to the process, ceramic slurry for continuous coating;

[0037] S2: pole piece drying 1: Put the pole piece coated on side A into the oven for drying, and take it back to the coating head for standby after winding;

[0038] S3: Gap coating 2: The die head of the coating machine continues to use the positive electrode slurry and the ceramic slurry to coat the electrode piece on the A side after coating and drying on the B side, and the positive electrode slurry is gap coated according to the process during coating Dislocation between cloth and surface A, continuous coat...

Embodiment 3

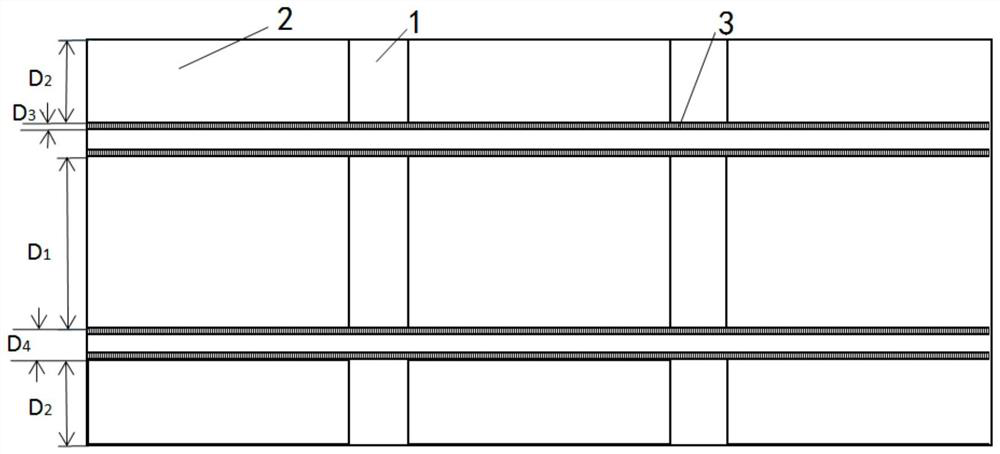

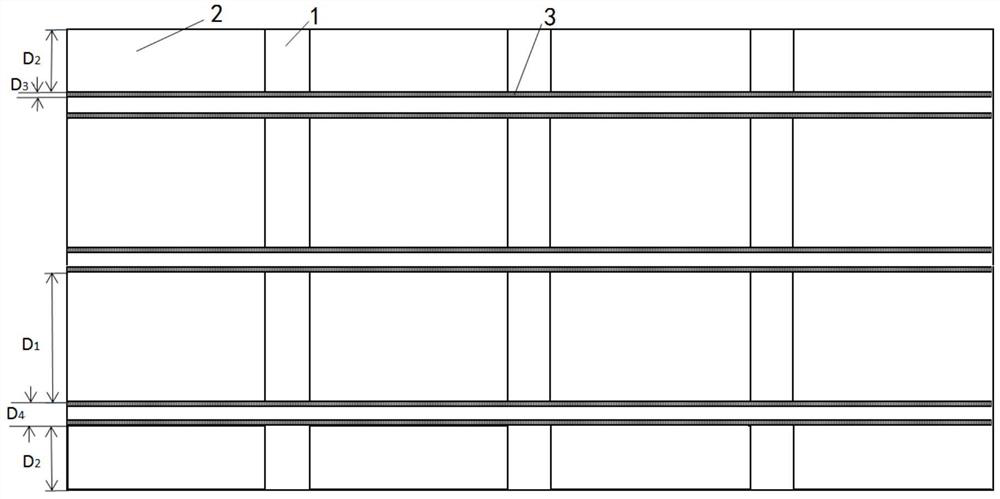

[0041] A lithium-ion battery positive pole piece, prepared according to the method described in Example 2, with a structure such as figure 1 As shown, it includes an aluminum foil 1 and a positive electrode slurry layer 2 and a ceramic layer 3 coated on the aluminum foil 1, wherein a plurality of positive electrode slurry layers 2 are distributed on the aluminum foil 1 at intervals to form a matrix structure, along the length direction of the pole piece On, the gap L between two adjacent positive electrode slurry layers 2 3 is 50mm, along the pole piece width direction, the gap D between two adjacent positive electrode slurry layers 2 4 45mm, the aluminum foil 1 in the gap is exposed, and the ceramic layer 3 is coated on the aluminum foil 1 in the gap between the adjacent positive electrode slurry layers 2. Four ceramic layers 3 are arranged in parallel and at intervals along the width direction of the pole piece. Each ceramic layer 3 width D 3 It is 10mm, and it is in conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com