Patents

Literature

37results about How to "Improve sewing precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

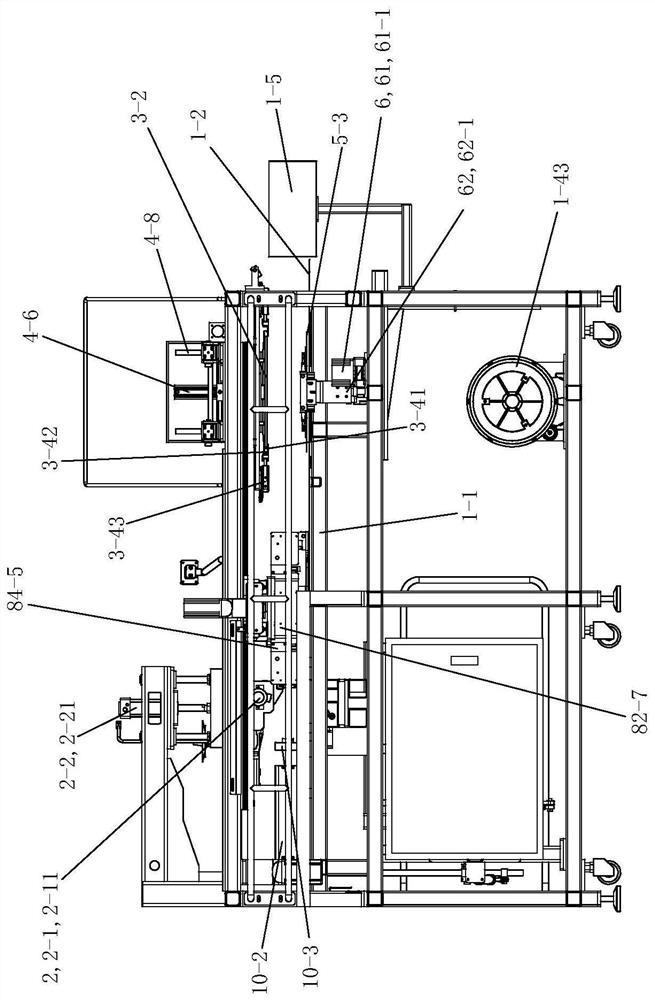

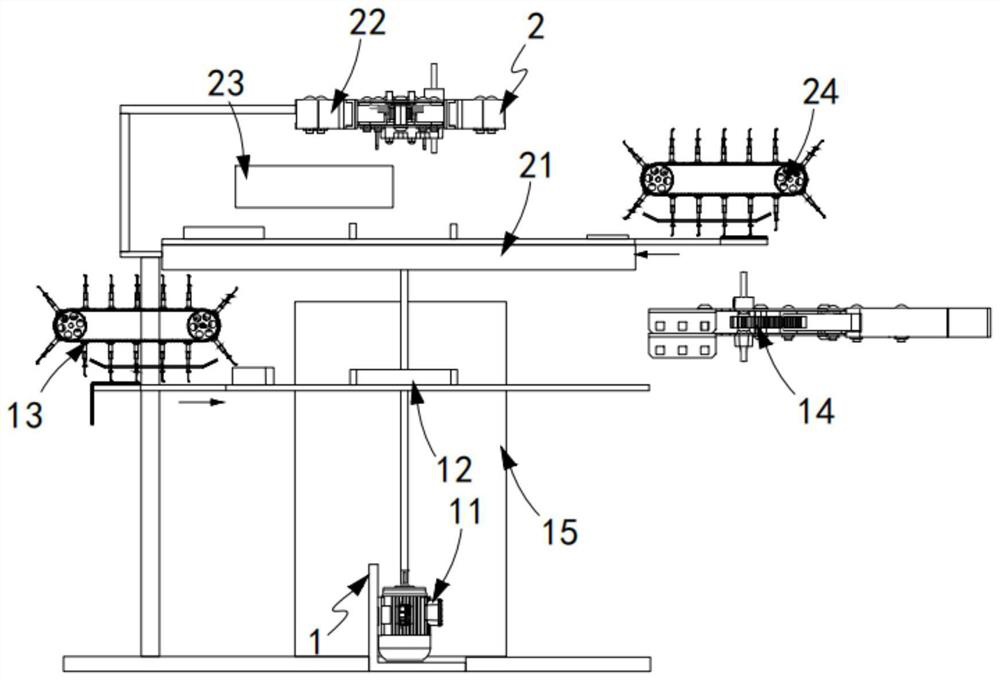

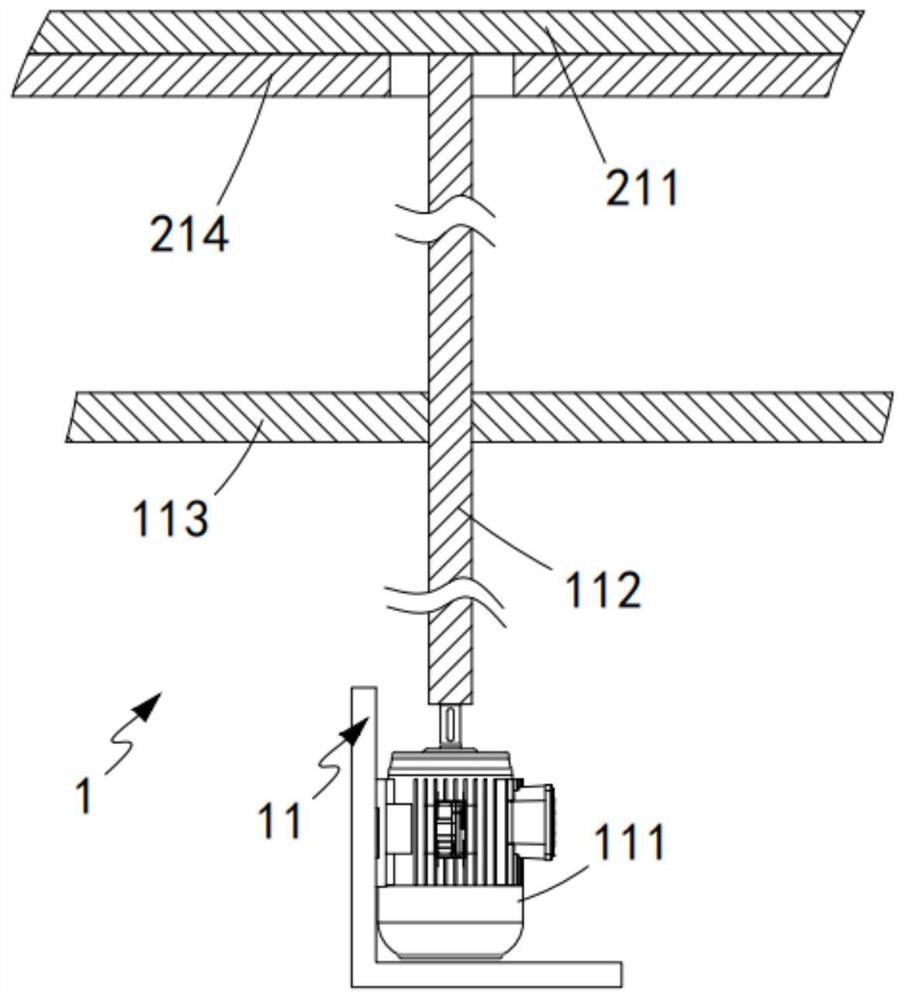

Full-automatic multi-trim-strip sewing equipment

ActiveCN107190425ASimple structureSewn flatWorkpiece carriersWork-feeding meansEngineeringSewing machine

The invention discloses full-automatic multi-trim-strip sewing equipment. The full-automatic multi-trim-strip sewing equipment comprises a sewing device, wherein the sewing device comprises a multi-needle sewing machine, a trim-strip feeding device, a first work platform, an upper tug assembly and a lower tug assembly. The full-automatic multi-trim-strip sewing equipment is characterized by further comprising a feeding device, and lower tugs of the lower tug assembly are driving wheels. The feeding device comprises a discharging table assembly, a feeding table assembly, pressing foot assemblies, and a pressing foot two-stage driving assembly. A discharging panel of the discharging table assembly is arranged on a discharging shelf in a way of moving front and back, and a feeding table panel of the feeding table assembly is fixedly arranged on a feeding table mounting shelf. The feeding table surface is communicated with a first panel and a discharging panel of the first work platform. The pressing foot assemblies comprise pressure feet. The pressure feet are arranged above the discharging panels, a feeding table panel, and the first panel in a way of moving left and right through the pressing foot two-stage driving assembly, and are used for delivering fabric of to-be-sewed trim-strips located on the discharging panel to the first panel through the feeding table panel after pressing the fabric.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

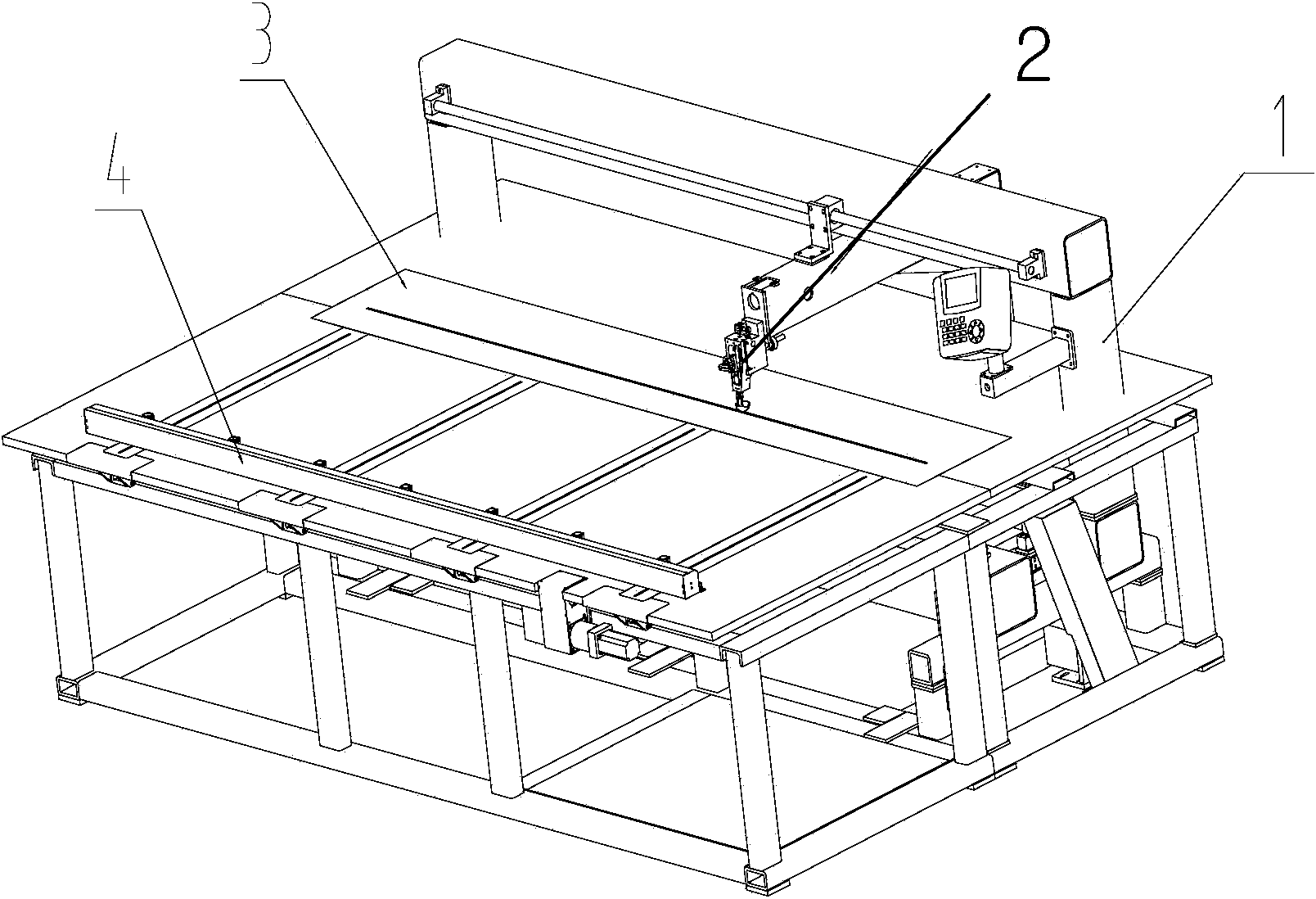

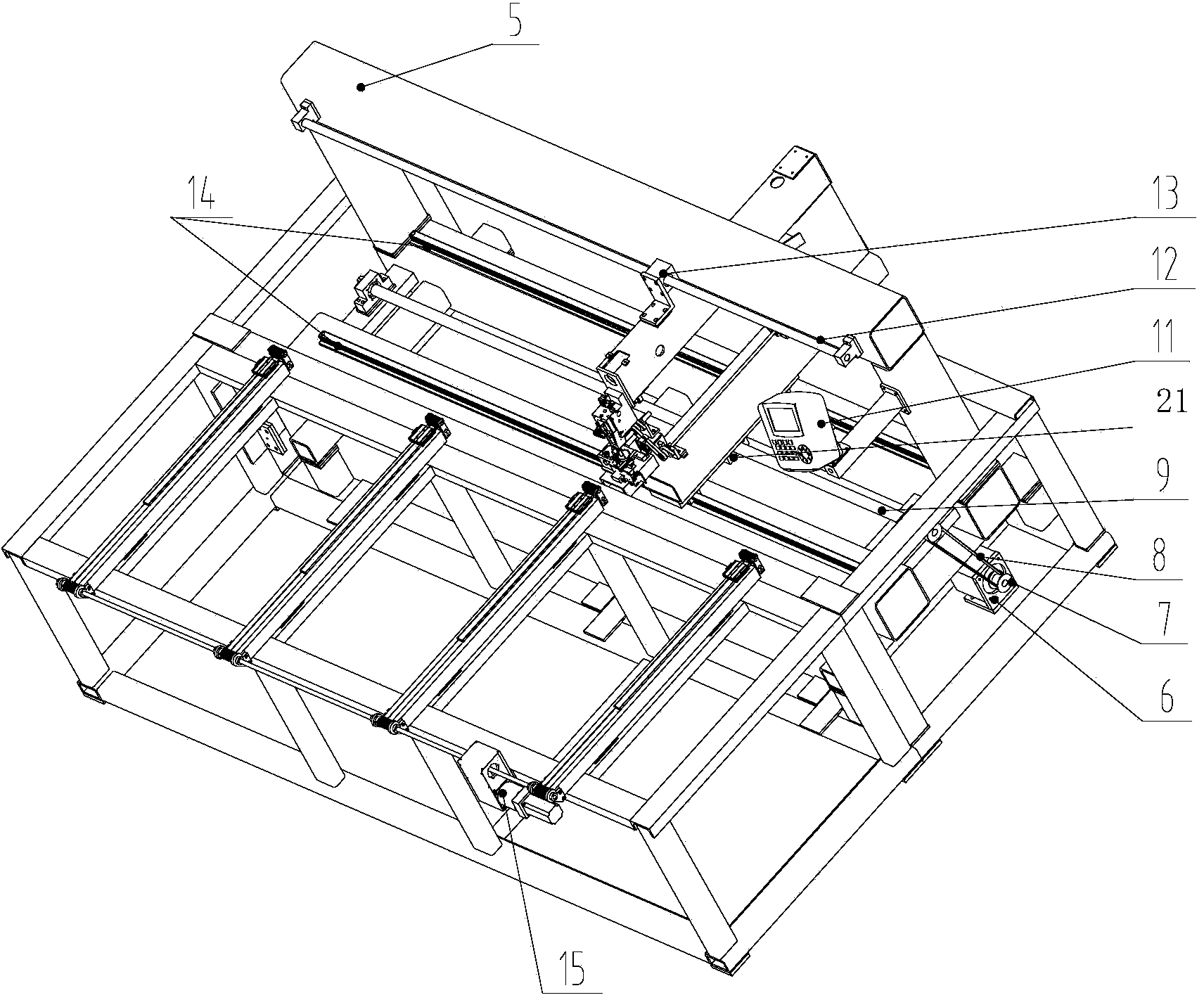

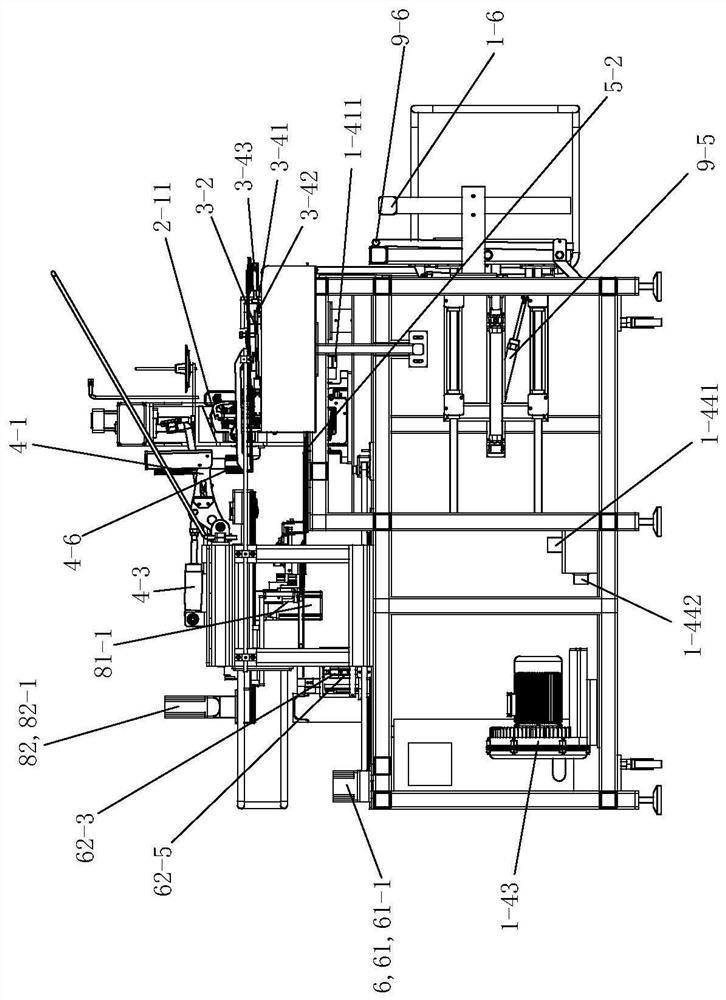

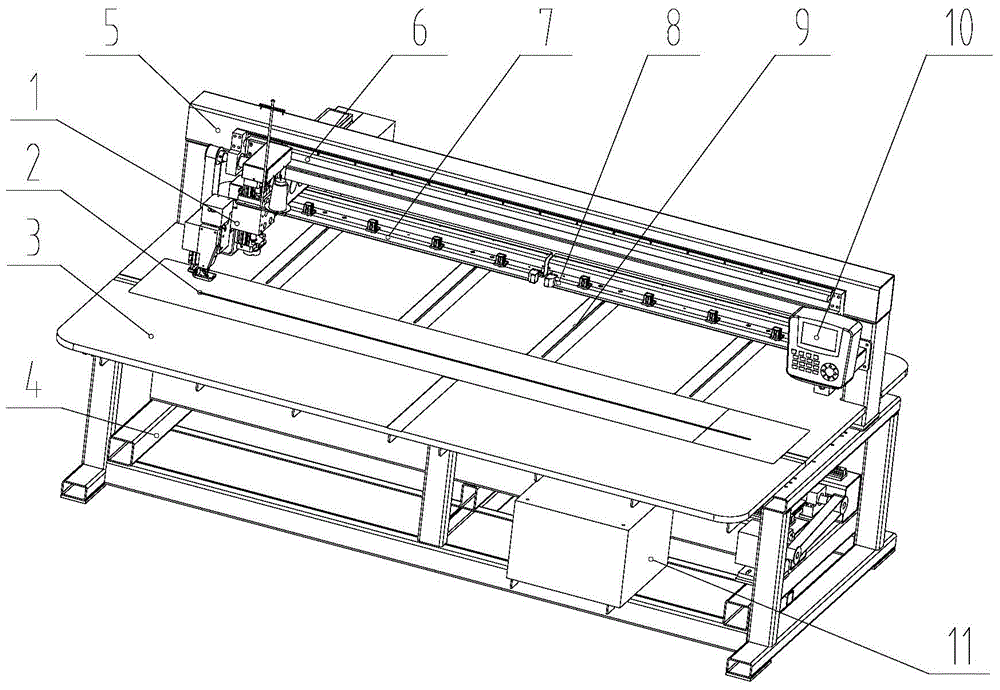

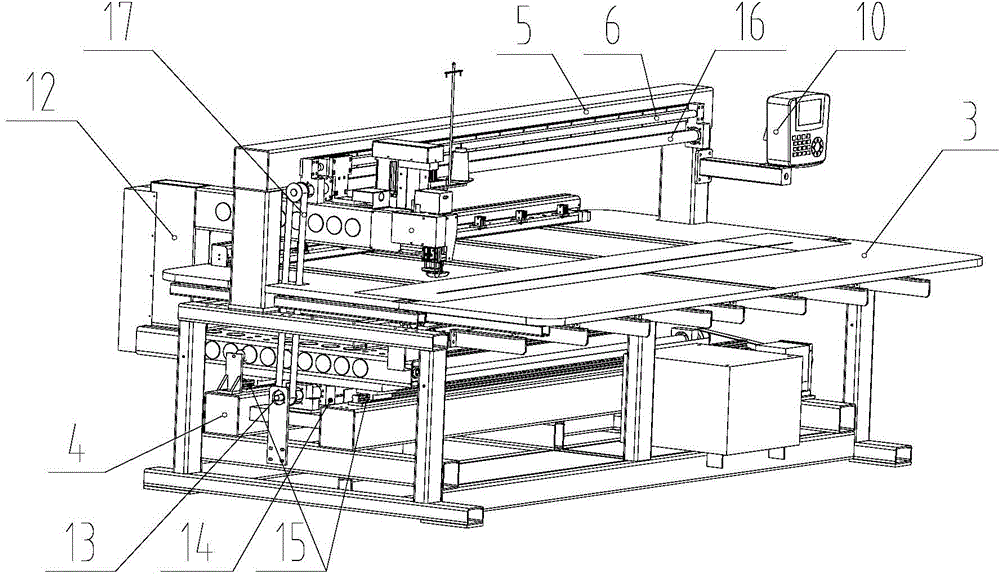

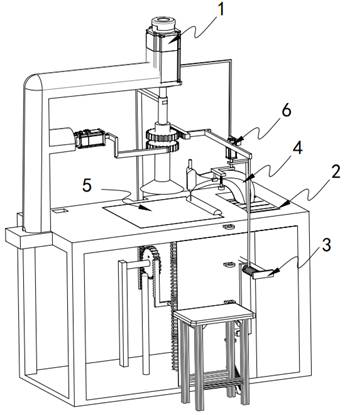

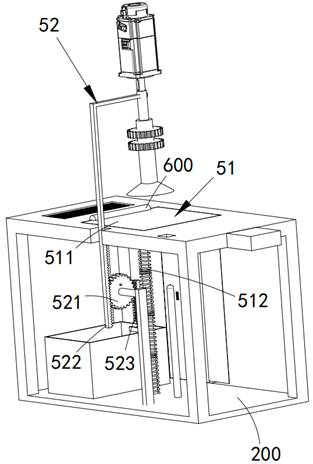

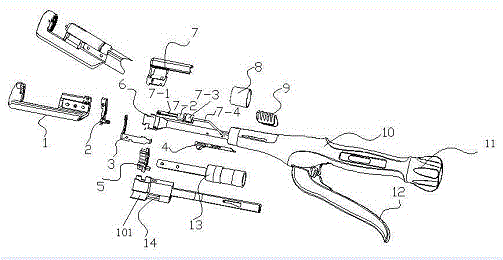

Full-automatic sleeping bag sewing machine

InactiveCN104060404ASmall structure sizeImprove stabilityWork-feeding meansSack sewingCantileverComputer control

The invention discloses a full-automatic sleeping bag sewing machine which comprises a machine frame, a machine head capable of moving in the X direction, a platen, a machine frame cross beam, an automatic sewing frame which is mounted on the platen and can move in the Y direction, and a computer control box mounted on one side of the machine frame cross beam. The platen and the machine frame cross beam are mounted on the machine frame. The machine head is fixedly connected to a cantilever structure composed of a machine head upper horizontal beam, a machine head vertical beam and a machine head lower horizontal beam. The bottom of the machine head lower cross beam is provided with a screw rod nut and two linear guide rail seats. The machine frame is provided with a screw rod which is in transmission connection with the screw rod nut, and the machine frame is further provided with two linear guide rails which are in matched connection with the two linear guide rail seats. The screw rod and the two linear guide rails are all arranged in the X direction, and the end of the screw rod is in transmission connection with an X-direction motor which is fixed on one side of the machine frame. Through the mode, the overall structural size of the machine is small, the length is reduced by a half compared with an existing machine model, and the overall stability of the machine and the sewing precision of the machine are improved.

Owner:上工富怡智能制造(天津)有限公司

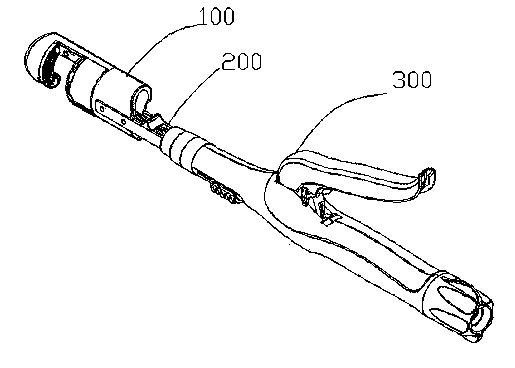

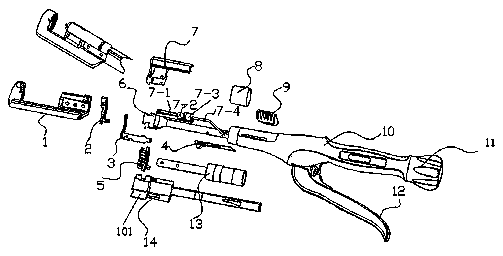

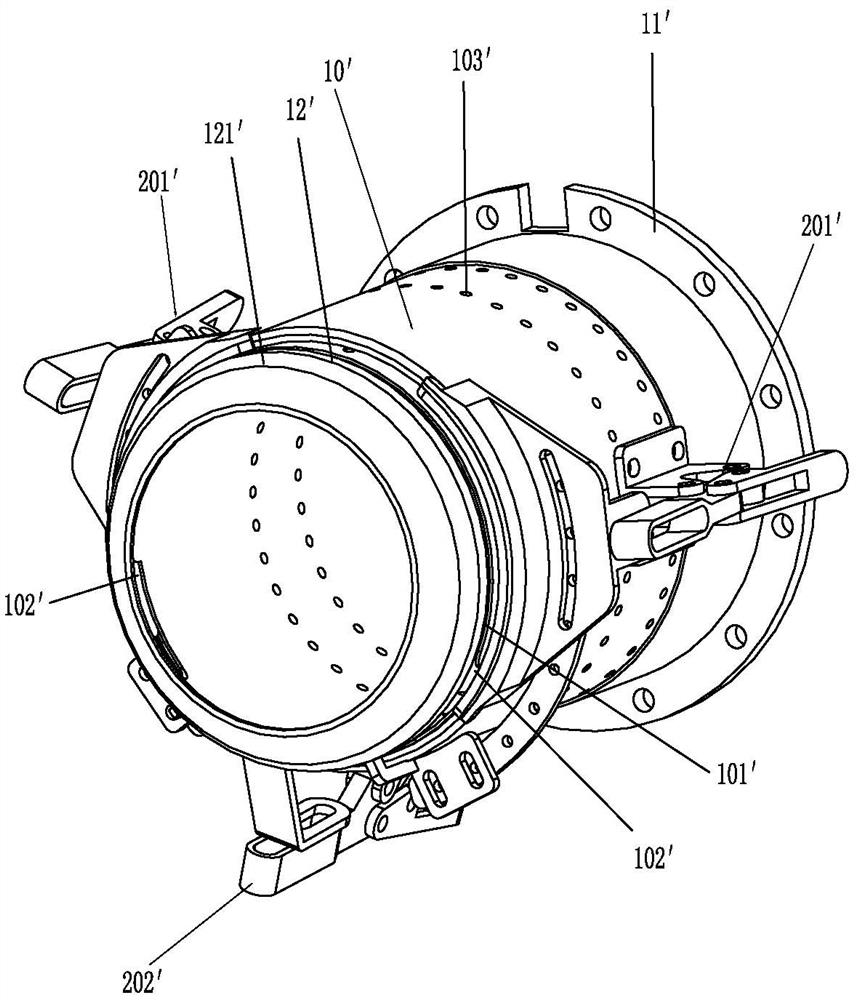

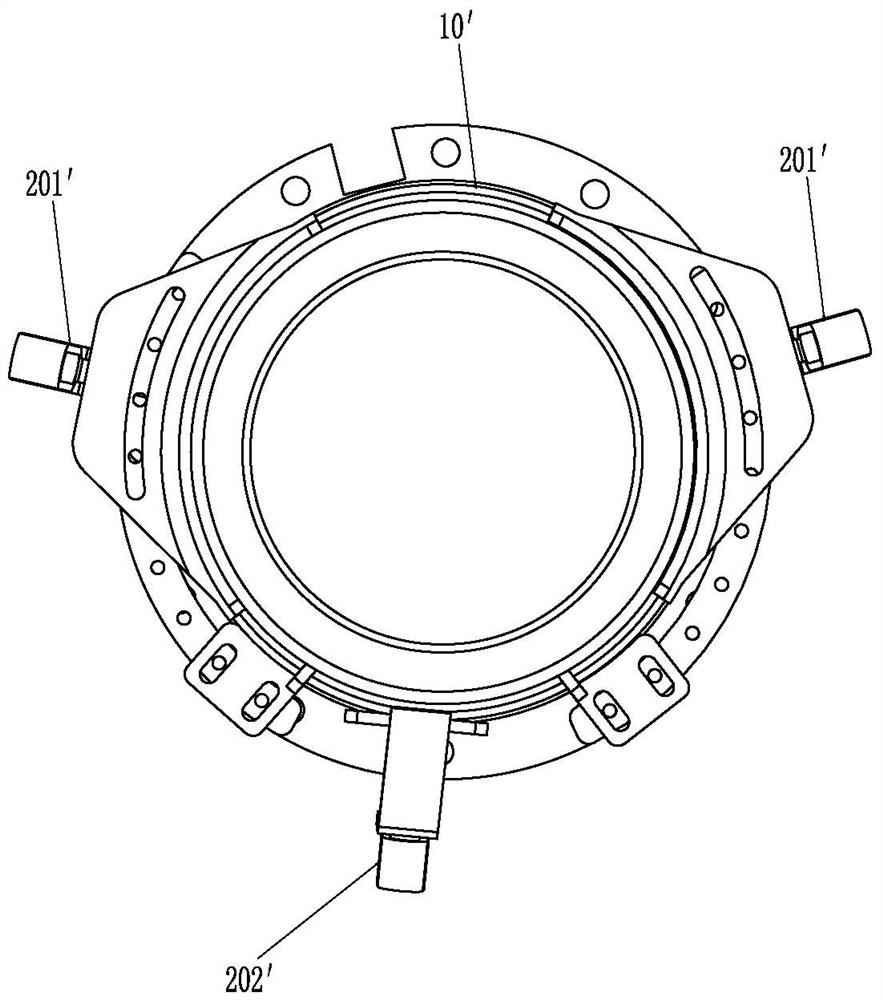

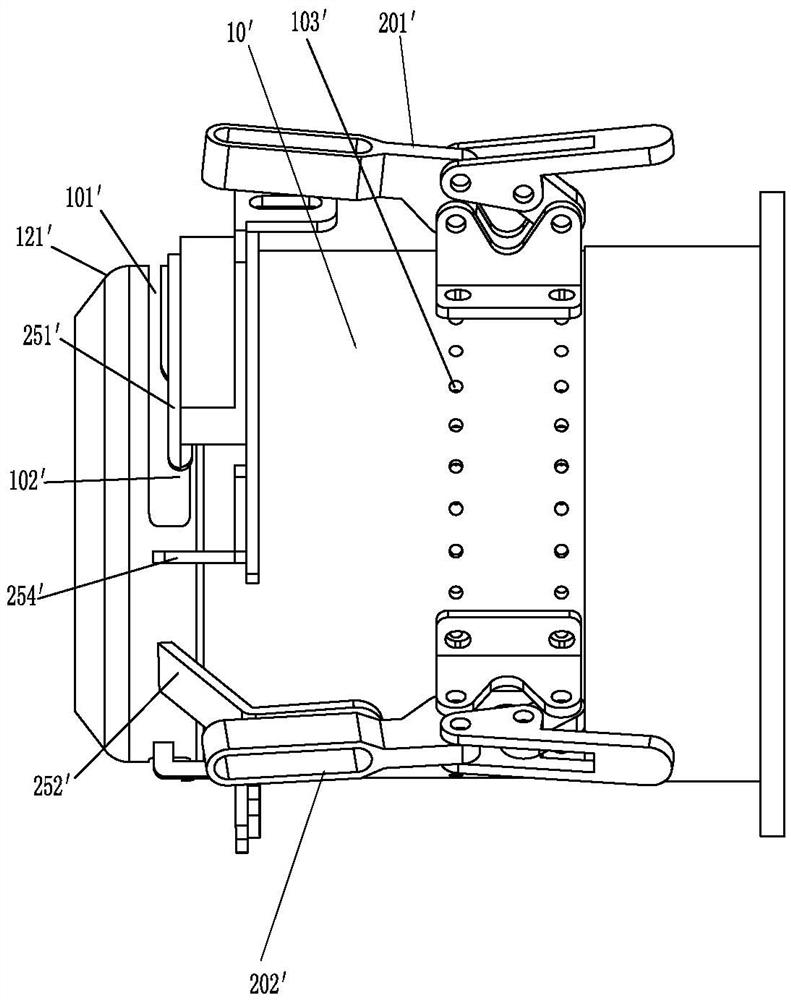

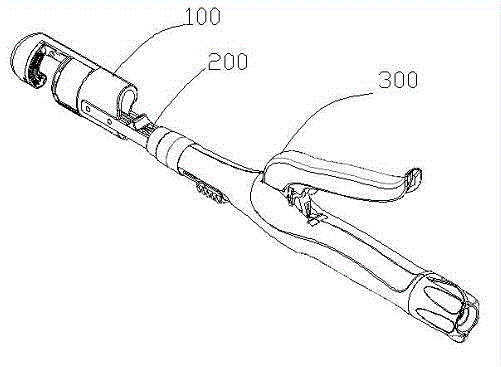

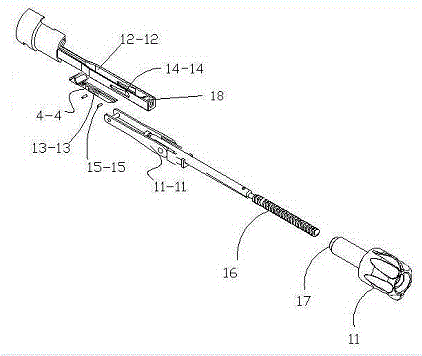

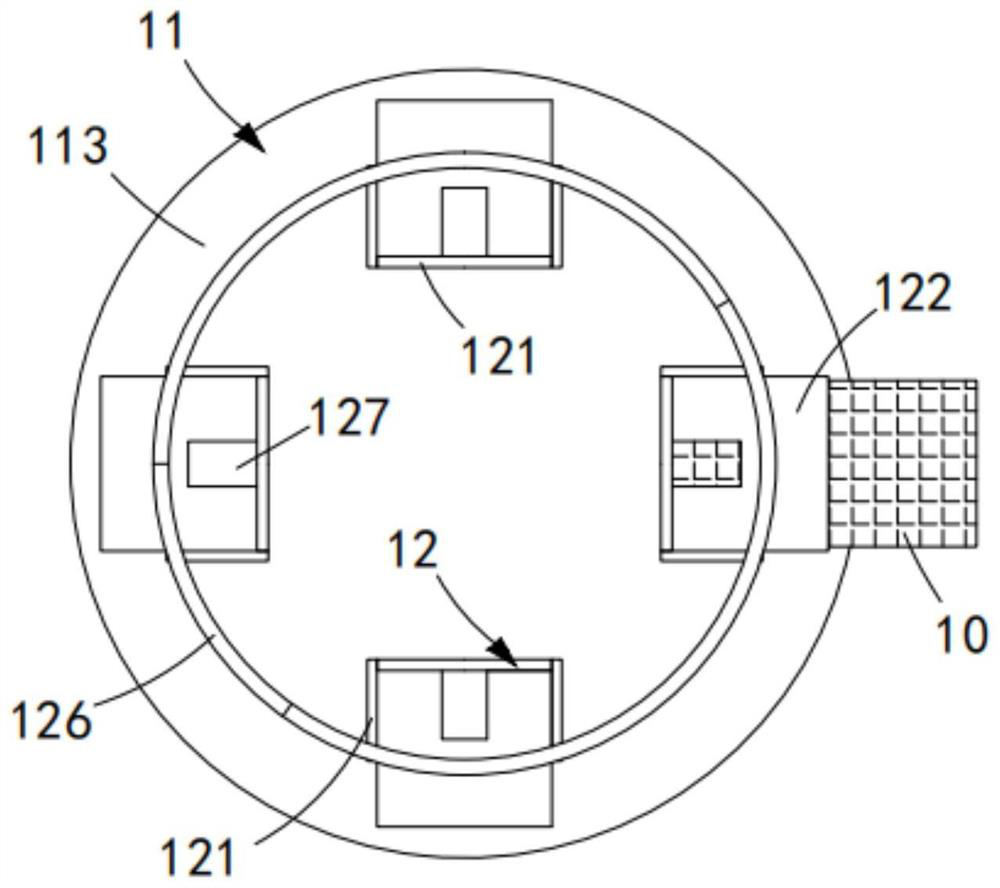

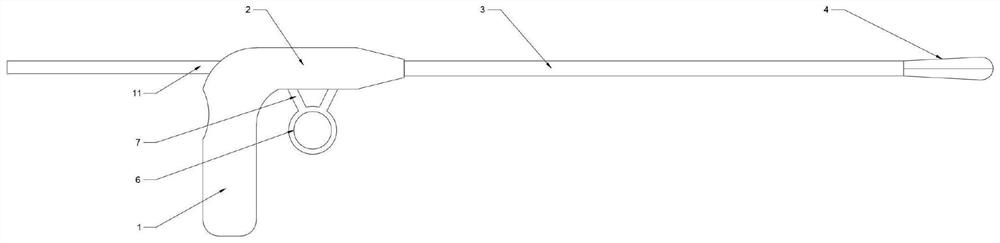

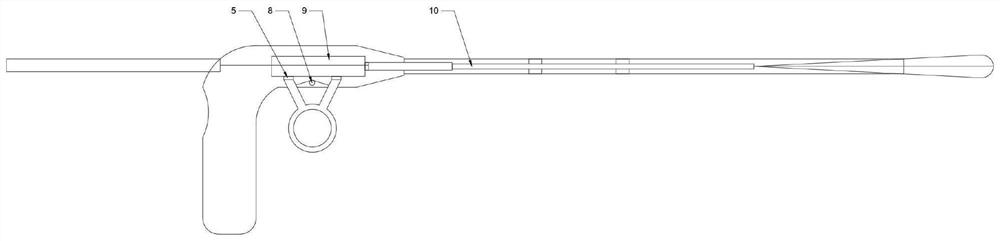

Disposable internal opening cutting and enclosing anastomat

ActiveCN104224259AResolve the bleedingReduce stenosisDiagnosticsSurgical staplesEngineeringBiomedical engineering

The invention relates to the technical field of disposable anastomats, in particular to a disposable internal opening cutting and enclosing anastomat. The disposable internal opening cutting and closing anastomat comprises a cutting molding assembly, a transmission assembly and a gun body provided with a triggering assembly, wherein the cutting molding assembly comprises a nail cabin bracket, a scalpel support ring, a nail pressing seat, a nail pushing device, a nail cabin support and a nail cabin; the nail cabin is clamped in a clamping groove of the nail cabin support through a buckle; the nail cabin support is directly connected with the gun body through the transmission assembly; the head of the nail cabin is circular-arc-shaped or parabolic; nail grooves of the nail cabin are of asymmetrical mode; the transmission assembly comprises a transmission lead screw; the lead screw is a large-screw-pitch left-handed lead screw; the tail end of the lead screw is connected with a corresponding lengthened nut assembly; the lengthened nut assembly and a knob positioned at the tail end of the gun body are molded together by injecting or embedded together; the gun body is a lever type or connecting-rod-type gun body. The disposable internal opening cutting and enclosing anastomat is skillful in design, and has a good application prospect; by adopting the disposable internal opening cutting and enclosing anastomat, a plurality of use problems in the prior art can be solved effectively.

Owner:JIANGSU QIANJING MEDICAL EQUIP

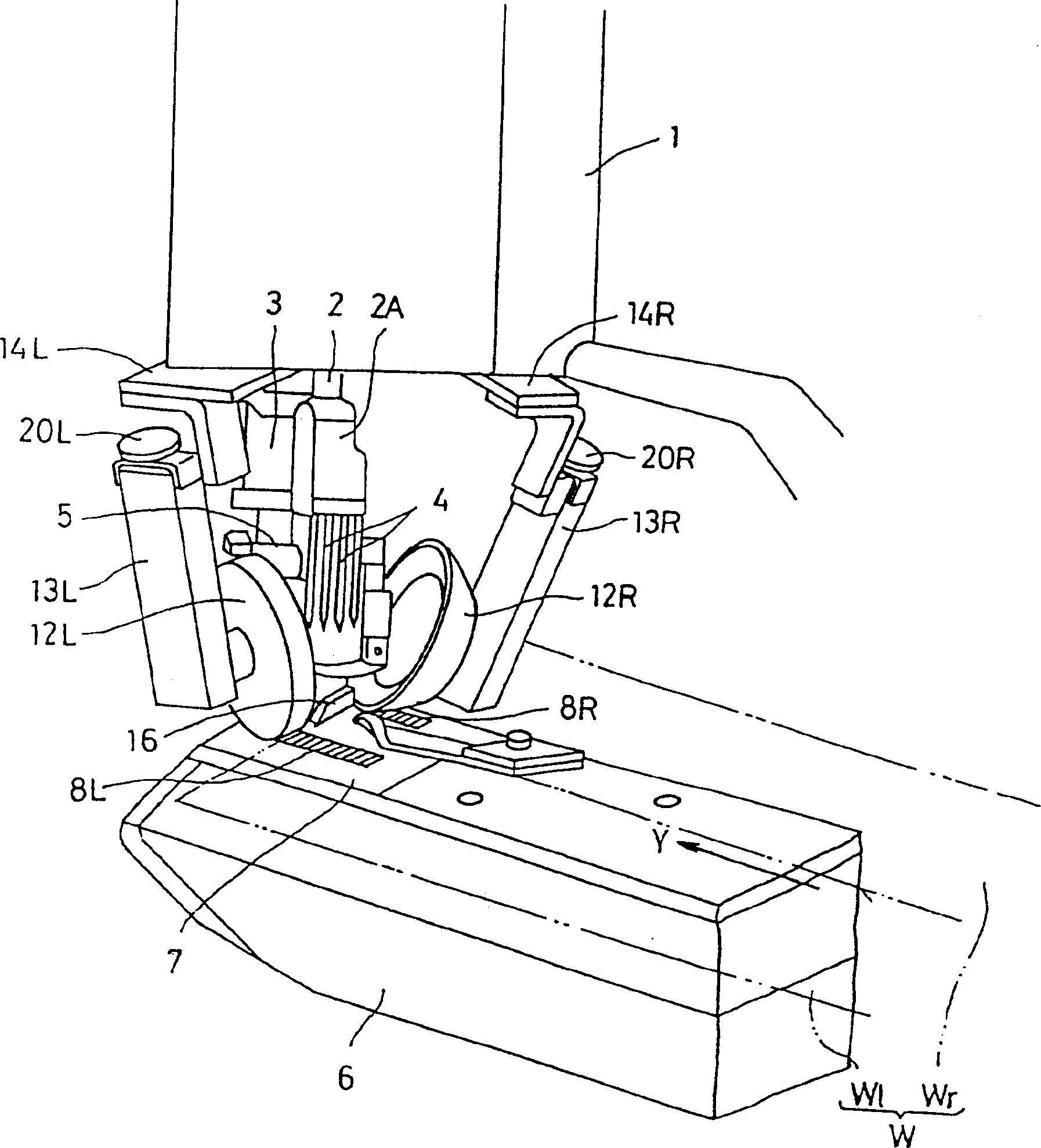

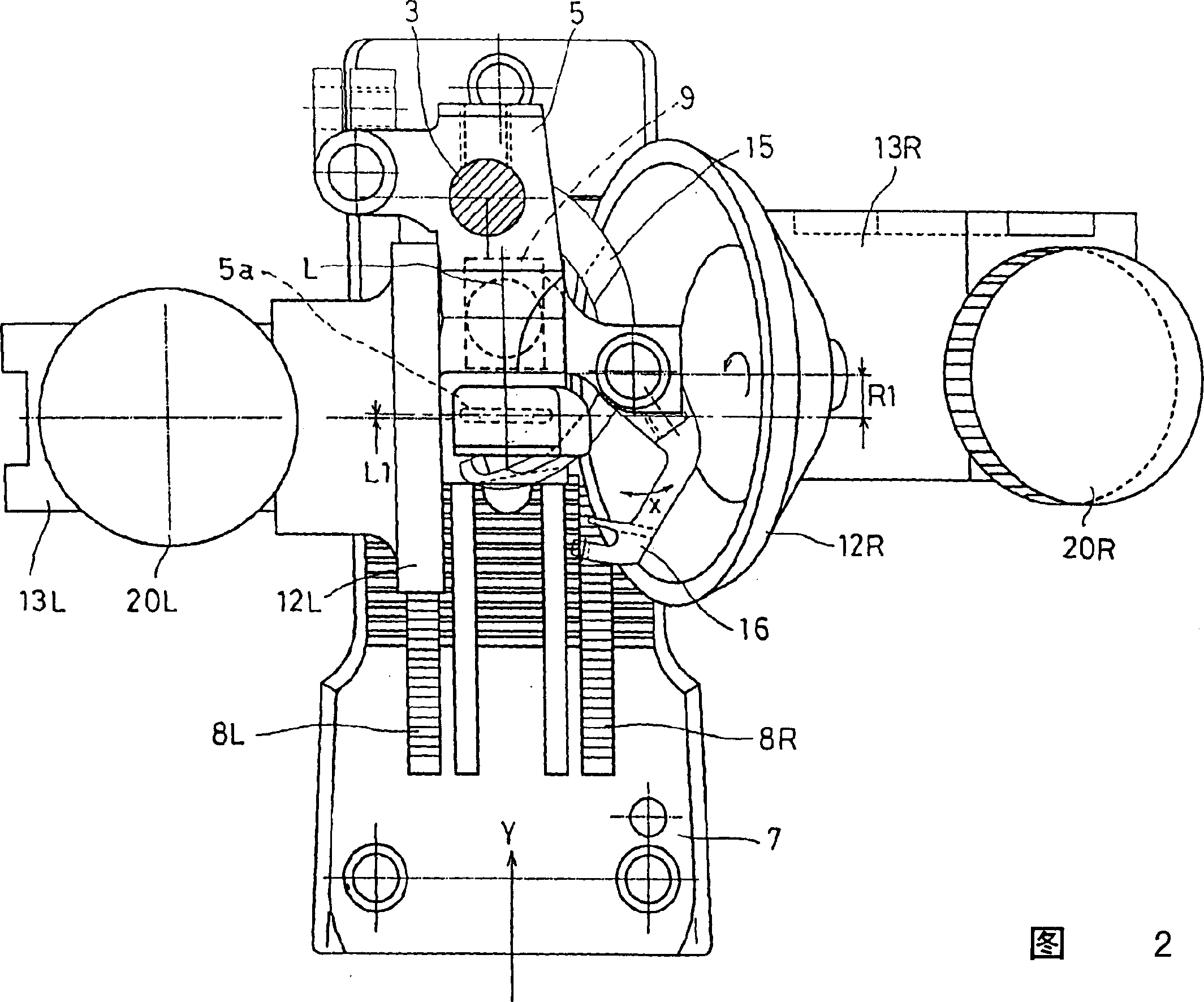

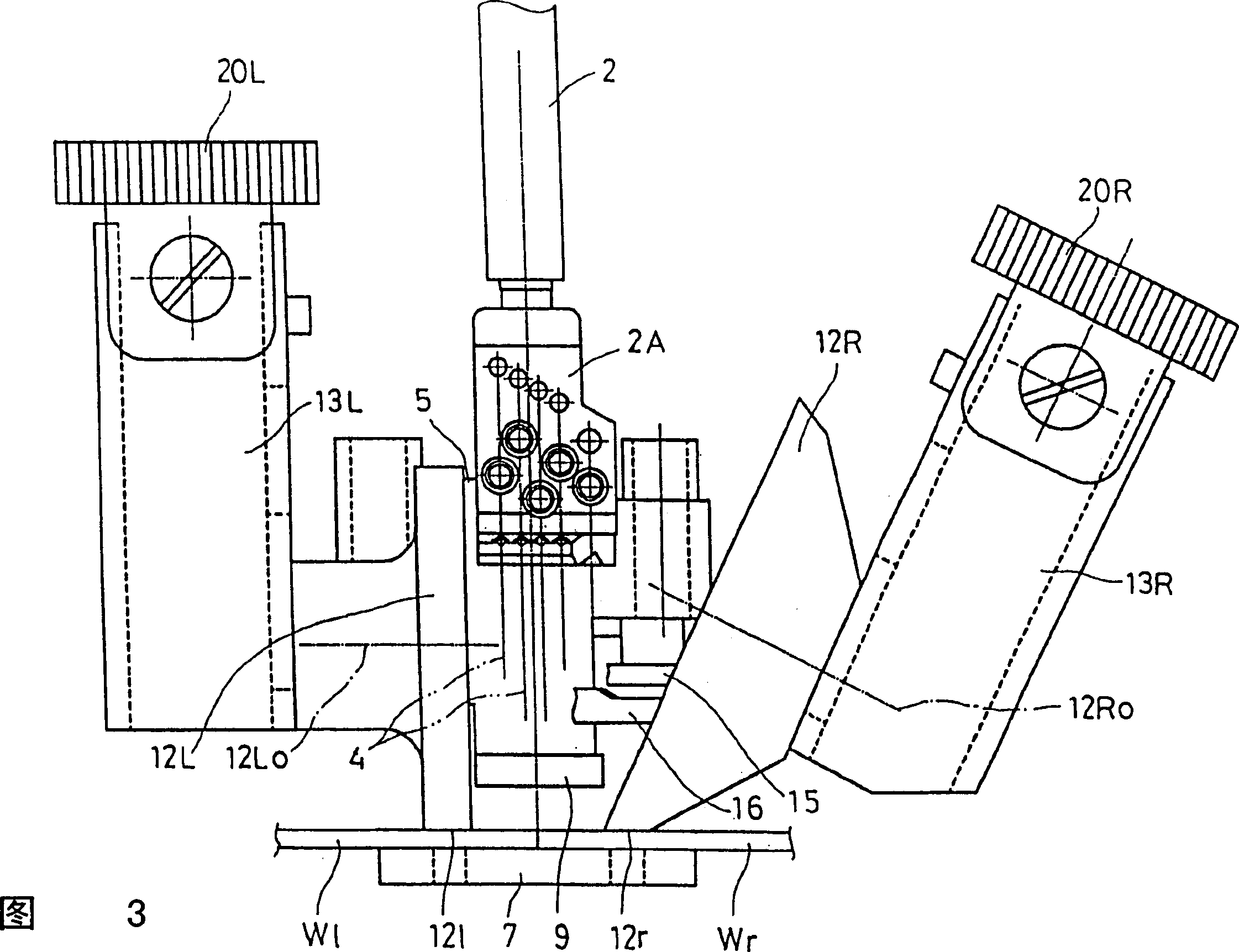

Cloth pressuring device of sewing machine

InactiveCN1397673AAvoid damageReduce frictional resistanceWork-feeding meansPressersEngineeringFeed dogs

In this invention, a small presser foot elastically pressing a fabric on the downstream side of a sewing direction of a needle location hole against moveable feed dogs on the top face side of a needle plate is mounted, a pair of right and left rotors and elastically pressing the fabric against the moveable feed dogs by the peripheral lower ends and are provided, and the straight line distance along the sewing direction between the peripheral lower ends and of the pair of right and left rotors and the pressing portion of the small presser foot is reduced as much as possible to the extent that there is no interference with operation. Accordingly, this invention is able to reliably, smoothly and uniformly feed fabric without necessitating the trouble of applying oil when sewing the less smooth fabric and easily carrying out a curve stitch and a fancy stitch.

Owner:YAMATO SEWING MASCH MFG CO LTD

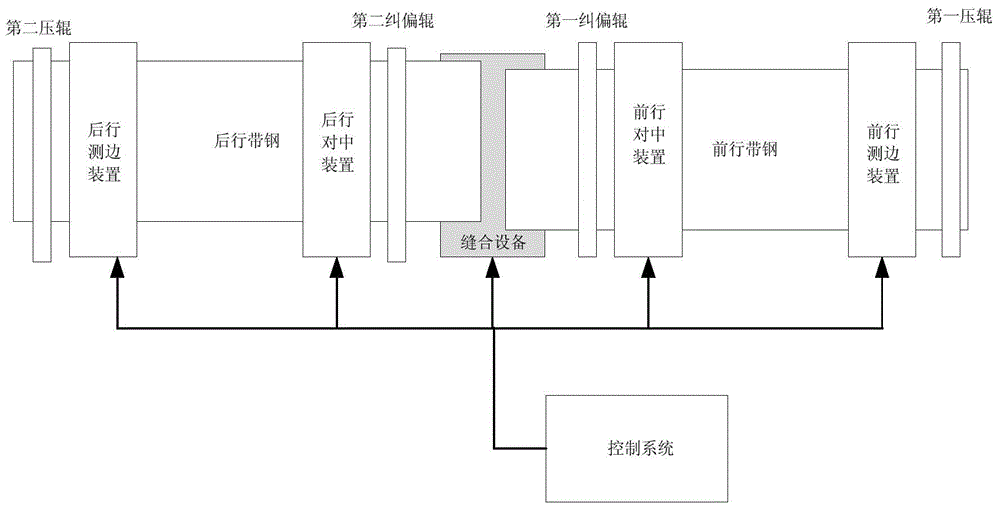

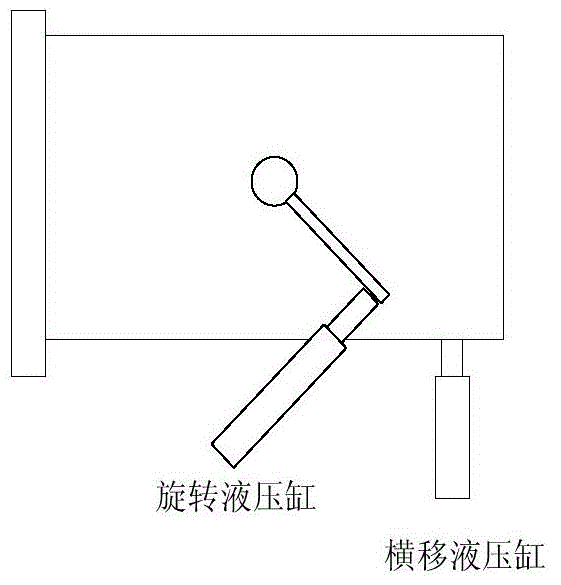

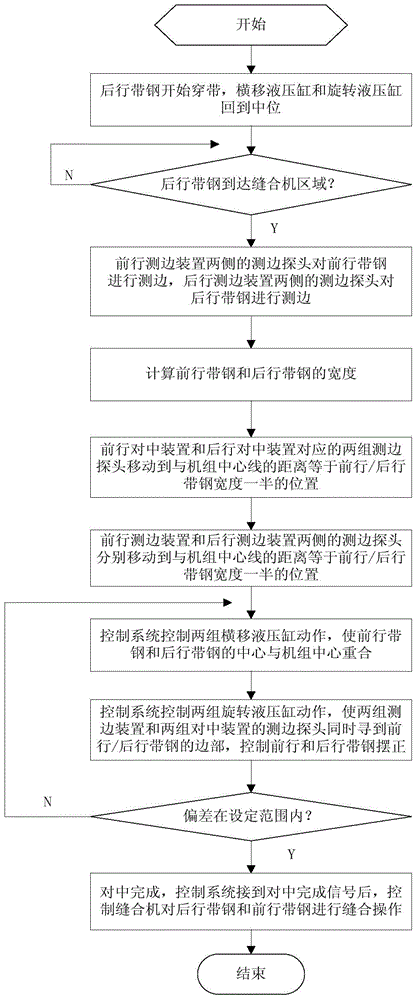

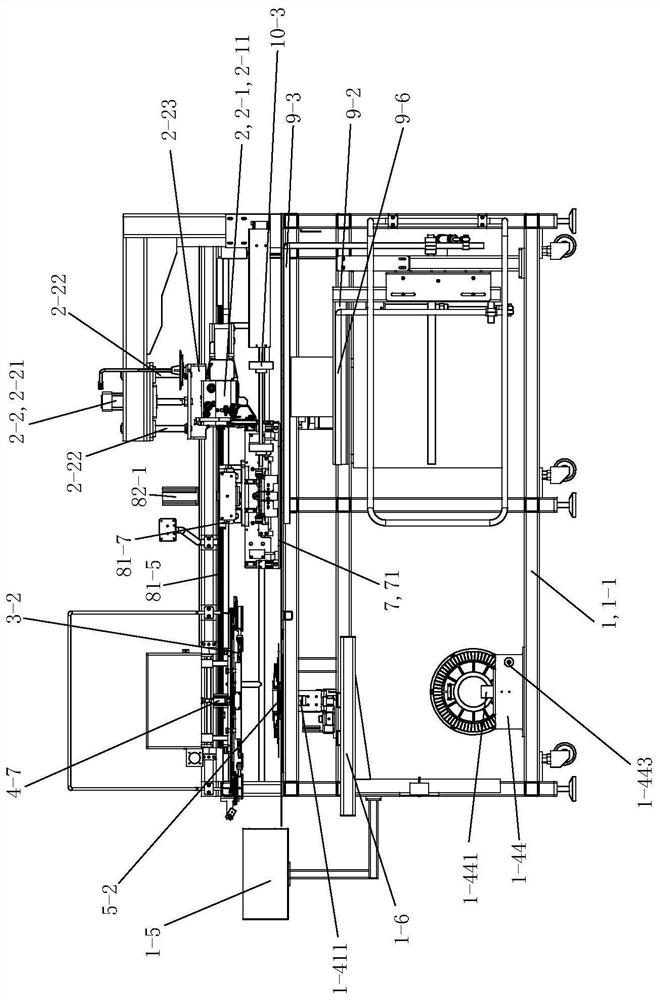

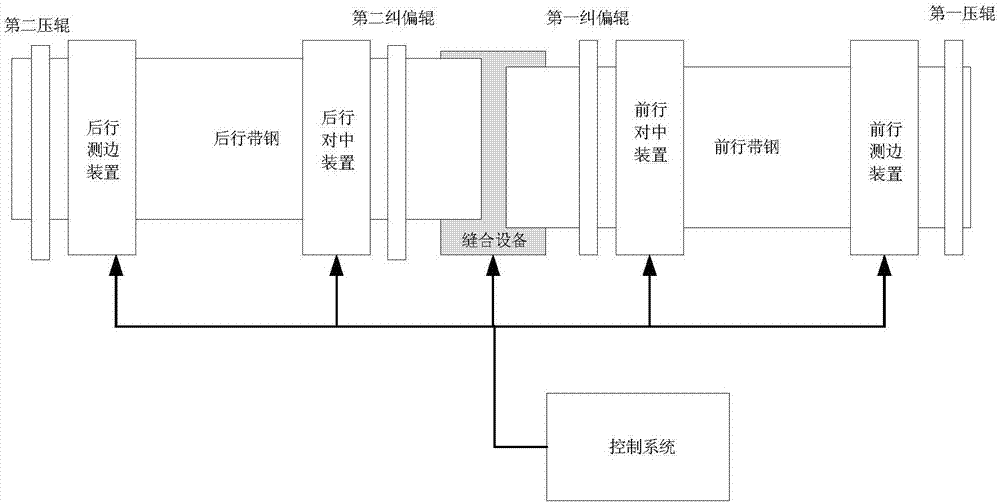

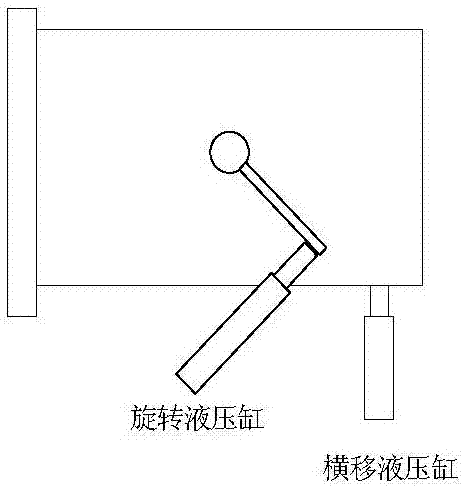

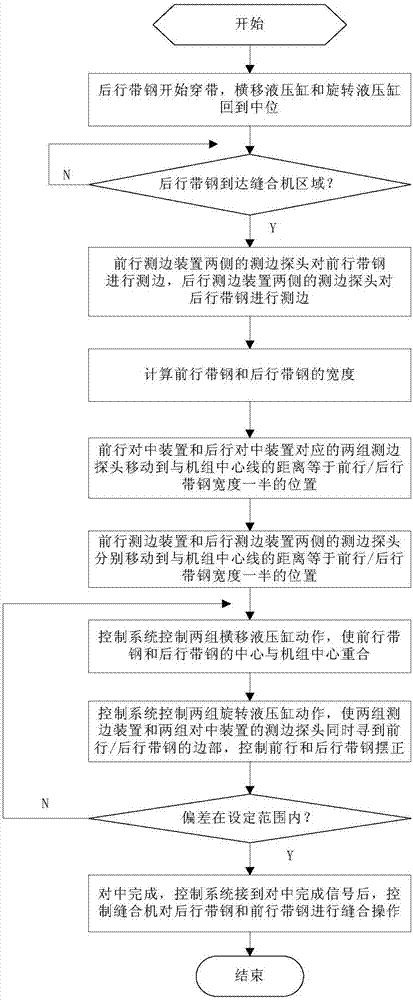

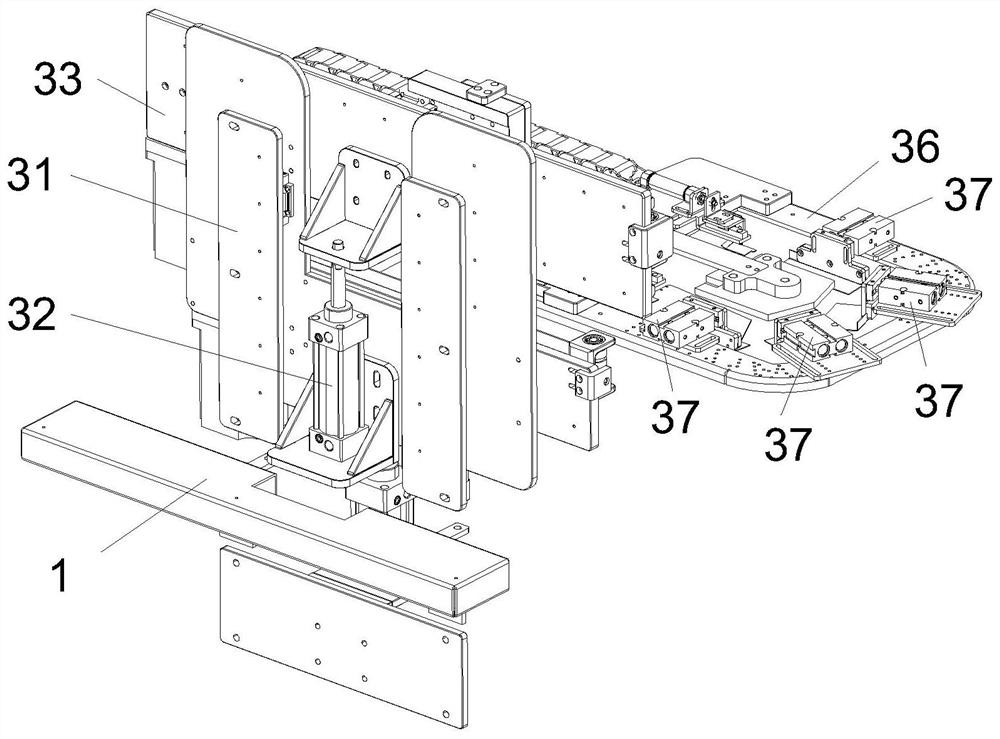

Control method and equipment for suturing and centering thin strip steel for continuous annealing furnace

ActiveCN105618596AReduce the risk of belt breakageImprove sewing precisionMetal-working feeding devicesMetal working apparatusHydraulic cylinderStructural engineering

The invention relates to the technical field of strip steel rolling, in particular to a control method and equipment for suturing and centering thin strip steel for a continuous annealing furnace. According to the control method and equipment, centering devices and side measuring devices are respectively adopted in the front and the back of suturing equipment, the centering devices are mainly used for detecting whether the center position of the strip steel moving forwards and the center position of the strip steel moving backwards are located in the center position of a unit, and the side measuring devices are mainly used for detecting whether the strip steel moving forwards and the strip steel moving backwards are placed right, namely whether the center line of the strip steel is parallel with the center line of the unit; a horizontal-moving hydraulic cylinder and a rotating hydraulic cylinder are respectively installed in front and back of the suturing equipment, the strip steel in front of the suturing equipment and the strip steel in back of the suturing equipment can be placed right and centered through cooperation between a first correction roller and a second correction roller, the suturing accuracy can be improved greatly, the strip breakage risk of the unit is lowered, and production is more smooth. According to the control method and equipment, the technical problems that existing control methods are poor in suturing accuracy and the strip breakage risk exists especially when the strip steel in front and the strip steel in back are different in width are solved.

Owner:BAOSHAN IRON & STEEL CO LTD

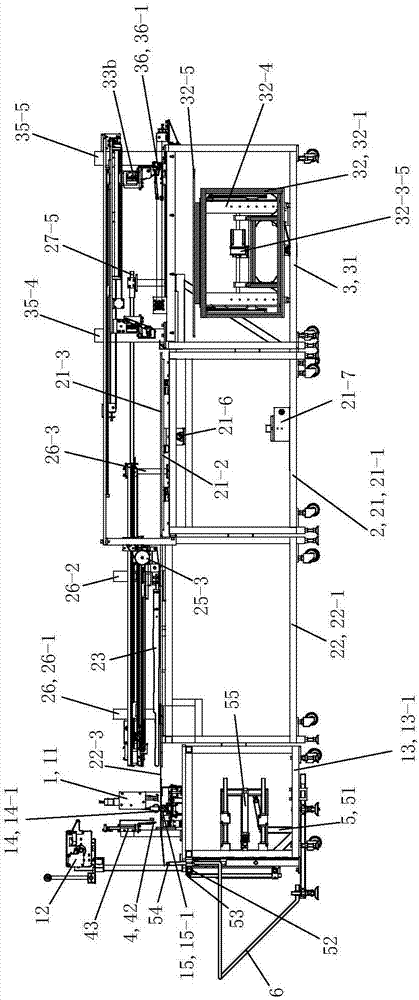

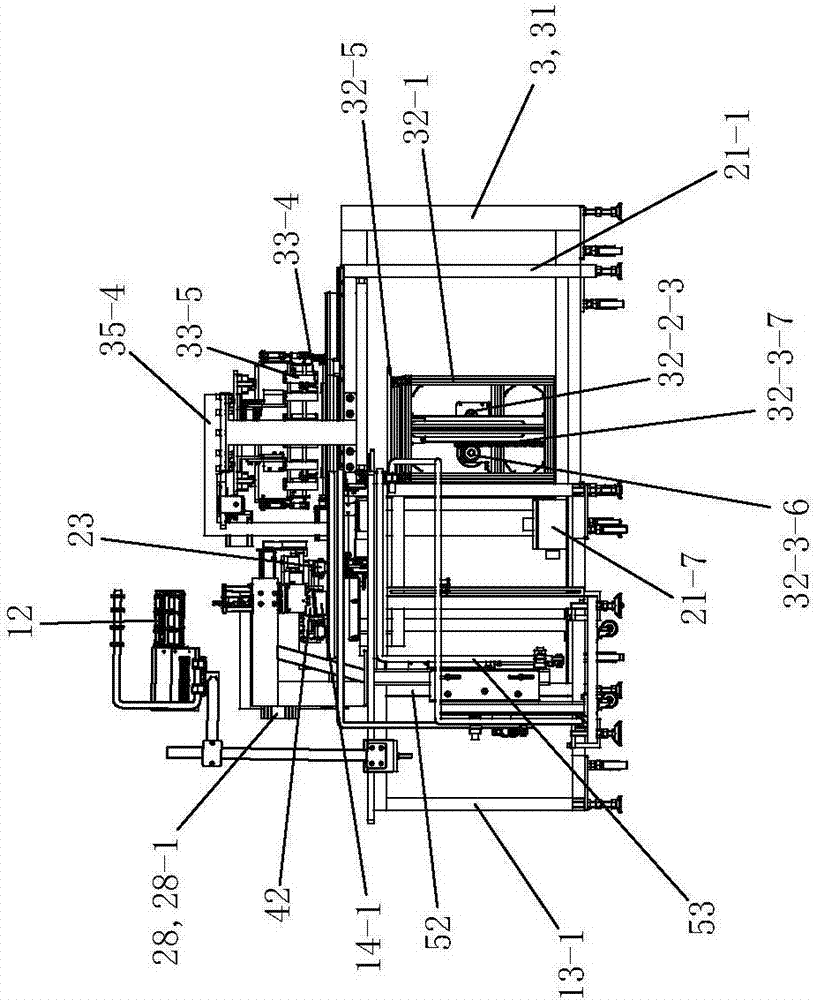

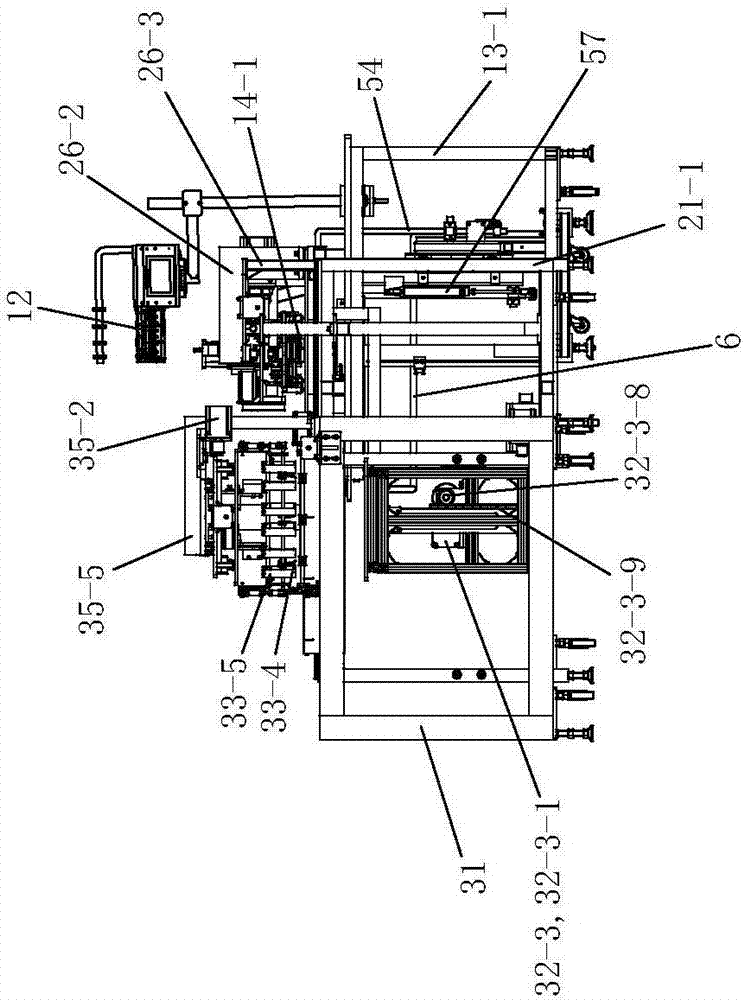

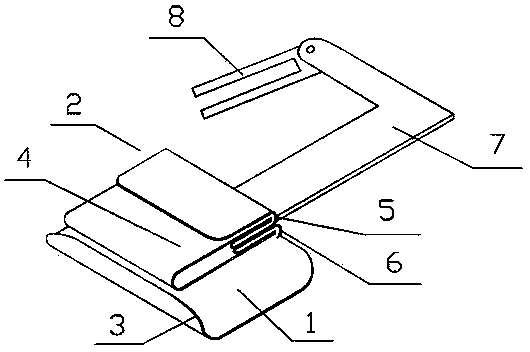

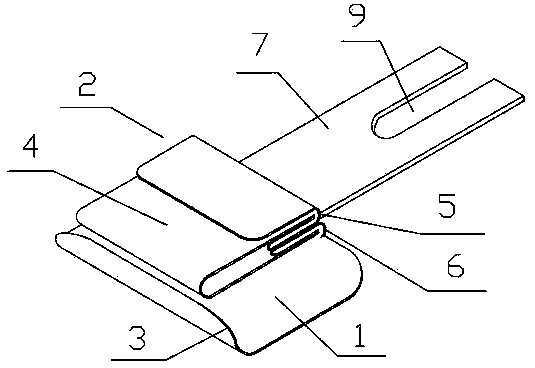

Kangaroo pocket sewing equipment

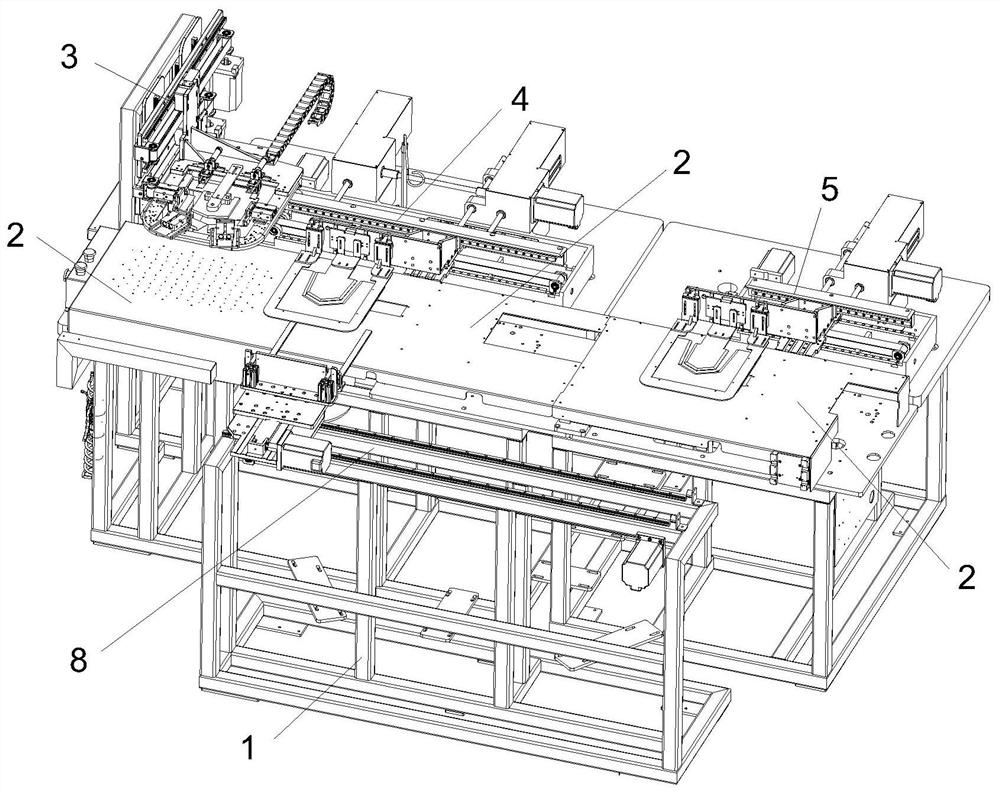

PendingCN111826820ASimple structureHigh degree of automationWork-feeding meansSewing-machine control devicesMechanical engineering

The invention discloses kangaroo pocket sewing equipment. The kangaroo pocket sewing equipment comprises a workbench assembly and a sewing assembly. The workbench assembly comprises a rack and a workbench plate. The workbench plate is horizontally and fixedly arranged on the rack. The sewing assembly is arranged on the right portion of the rack. The kangaroo pocket sewing equipment is characterized by further comprising an edge folding assembly, an edge folding driving device, a pocket-shaped plate assembly, a pocket-shaped plate driving device, a frame pressing device and a frame pressing driving device. The edge folding assembly cooperates with the pocket-shaped plate assembly to fold the edge of pocket cloth. The edge folding driving device drives the edge folding assembly to move up and down, and the pocket-shaped plate driving device drives the pocket-shaped plate assembly to move up and down and back and forth. The frame pressing device is used for conveying the folded pocket cloth and bodice cloth to the sewing assembly for sewing, and the frame pressing driving device drives the frame pressing device to move up and down, front and back and left and right.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

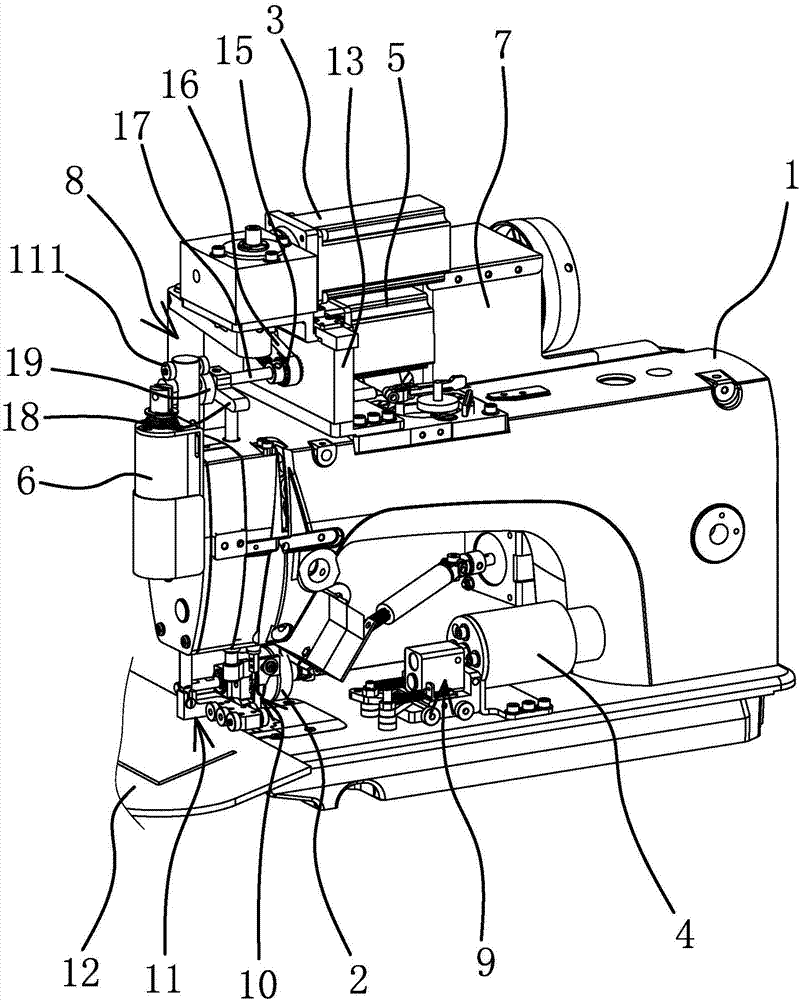

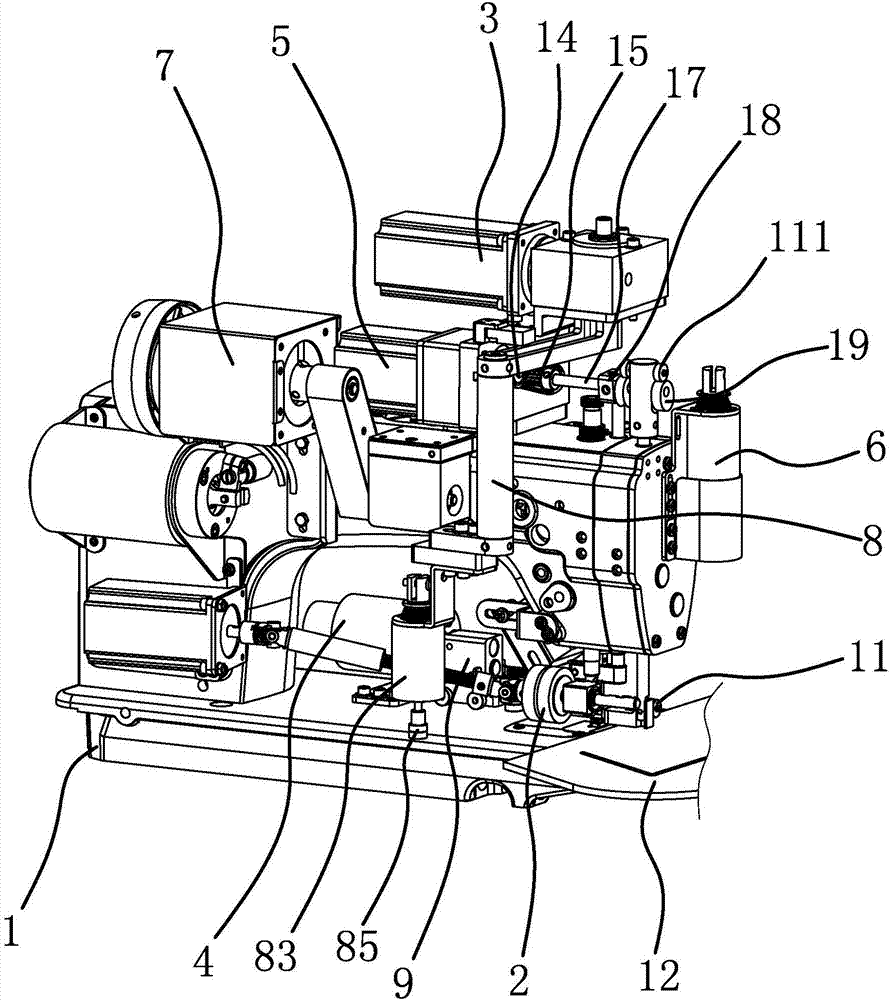

Cutter template sewing machine

ActiveCN107326542AImprove stabilityImprove sewing precisionWorkpiece carriersWork-feeding meansEngineeringSewing machine

The invention provides a cutter template sewing machine, and belongs to the technical field of sewing machines. The cutter template sewing machine solves the problem that existing sewing machines cannot be adopted to process curve stitches and are small in processing range. The cutter template sewing machine includes a machine head, a first driving source, a second driving source, a third driving source, a fourth driving source, a fifth driving source, a lever shifting mechanism, an abutment mechanism, a cutter mechanism and an external presser foot mechanism; a drawing wheel is arranged below the head of the machine head, the machine head is internally provided with a lifting pressing mechanism, and the lifting pressing mechanism is connected with the drawing wheel; the first driving source is connected with the lever shifting mechanism; the second driving source is connected with the abutment mechanism and can drive the abutment mechanism to abut against the side portion of a template; the third driving source is connected with the cutter mechanism and the external presser foot mechanism; the fourth driving source is connected with the cutter mechanism; the fifth driving source is connected with the cutter mechanism. The cutter template sewing machine has the advantages that the template can rotate, and the processing range is widened at the same time.

Owner:台州通宇服装机械科技有限公司

A preparation method of nano-microporous thermal insulation board

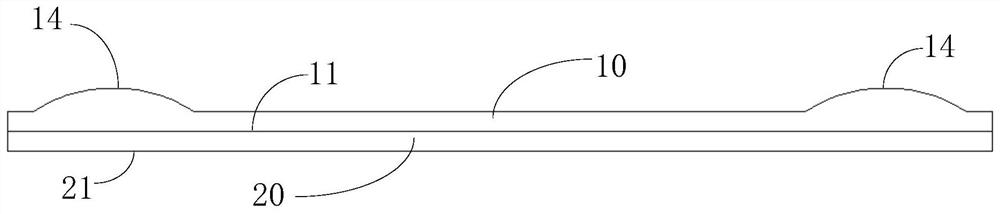

ActiveCN104527199BAvoid breakingEasy to operateLamination ancillary operationsThermal insulationFiberSilicon dioxide

The invention provides a preparation method of a nano microporous heat insulating panel. The preparation method of the nano microporous heat insulating panel comprises the following steps of: mixing nano silica powder, an infrared light shielding agent and an reinforcing agent uniformly, putting the mixture into a three-side stitched fiber cloth bag, and sewing the unstitched side of the fiber cloth bag; flattening and pressing the stitched fiber cloth bag to obtain a blocky panel; demolding and quilting the blocky panel to obtain the nano microporous heat insulating panel. Because the powdery raw materials are wrapped before being pressed and molded, the breakage of the panel can be avoided. In addition, because the fiber cloth bag is sewn simply on a workbench and does not need to be sewn in a mold, and the heat insulating surfaces of all wrapping fiber cloth do need to be divided into sewing sections, the operation is simple, and the efficiency is high. Furthermore, because a quilting machine is controlled by a computer to quilt the blocky panel, the operation is simple, and the blocky panel can be quilted accurately.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

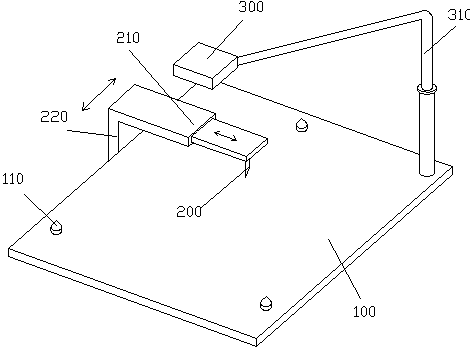

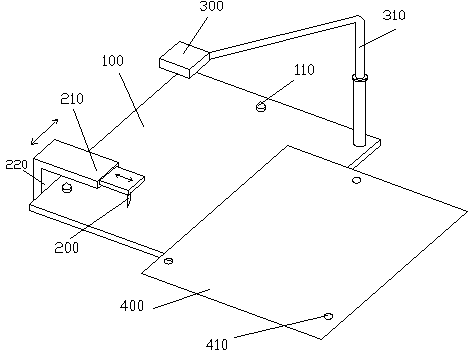

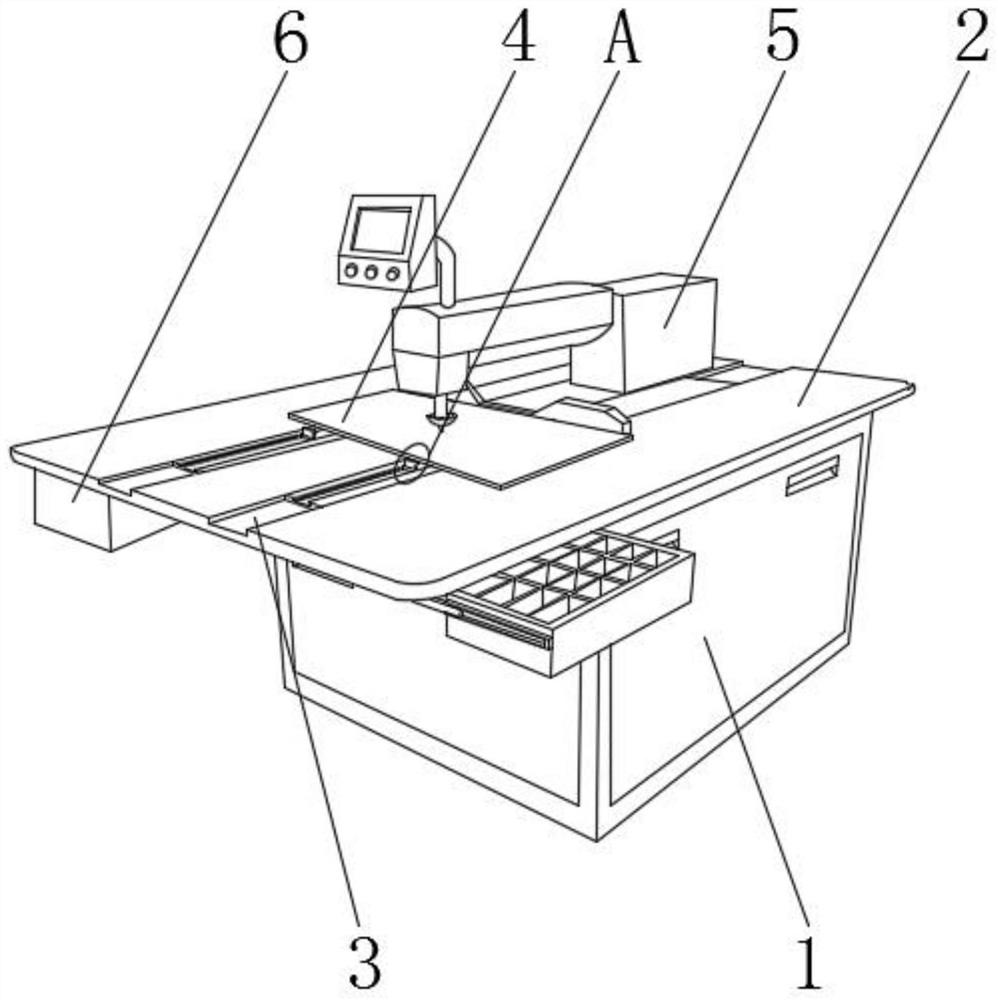

Tracking sewing equipment

InactiveCN103103697AImprove efficiencyGuaranteed stitching qualityProgramme-controlled sewing machinesEngineeringNumerical control

The invention provides tracking sewing equipment. The tracking sewing equipment comprises a sewing platform, wherein a numerical control (NC) two-shaft positioning device is arranged at the upper portion of the sewing platform and is provided with a sewing device and a tracking device, the sewing device faces the sewing platform, the sewing platform is provided with at least two positioning nails which are used for positioning a transparent hard film covered on the sewing platform, and the transparent hard film is provided with positioning holes corresponding to the positioning nails and traces clothes to be sewn arranged on the sewing platform through a tracing pen. According to the tracking sewing equipment, the tracking device is used for controlling the NC two-shaft positioning device to be matched with the sewing device to sew the clothes, compared with the traditional manual sewing method, the sewing efficiency is largely improved, and sewing quality is effectively guaranteed as sewing accuracy is improved.

Owner:WUJIANG LANRUITE TEXTILE

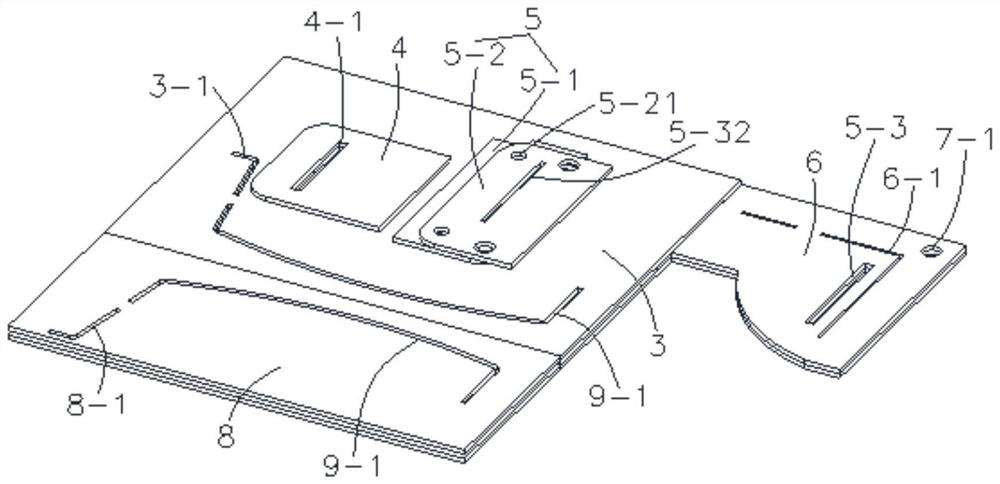

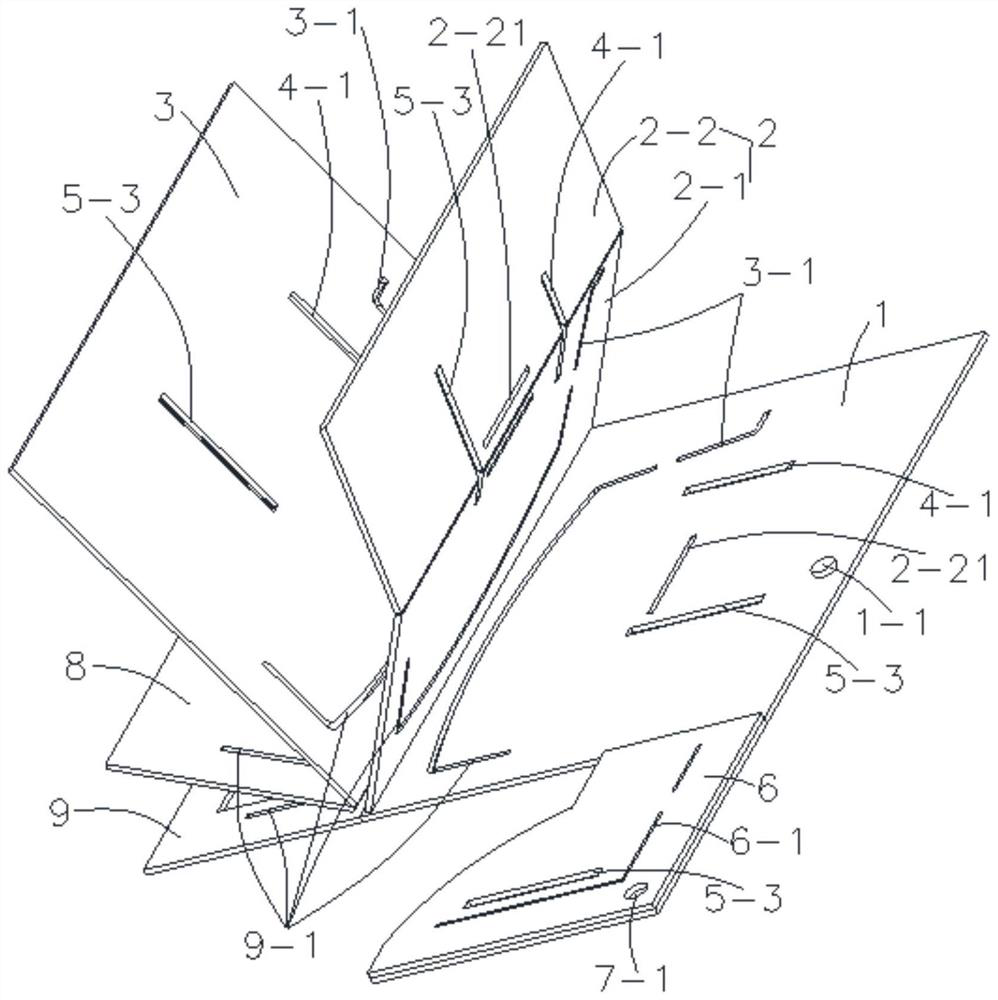

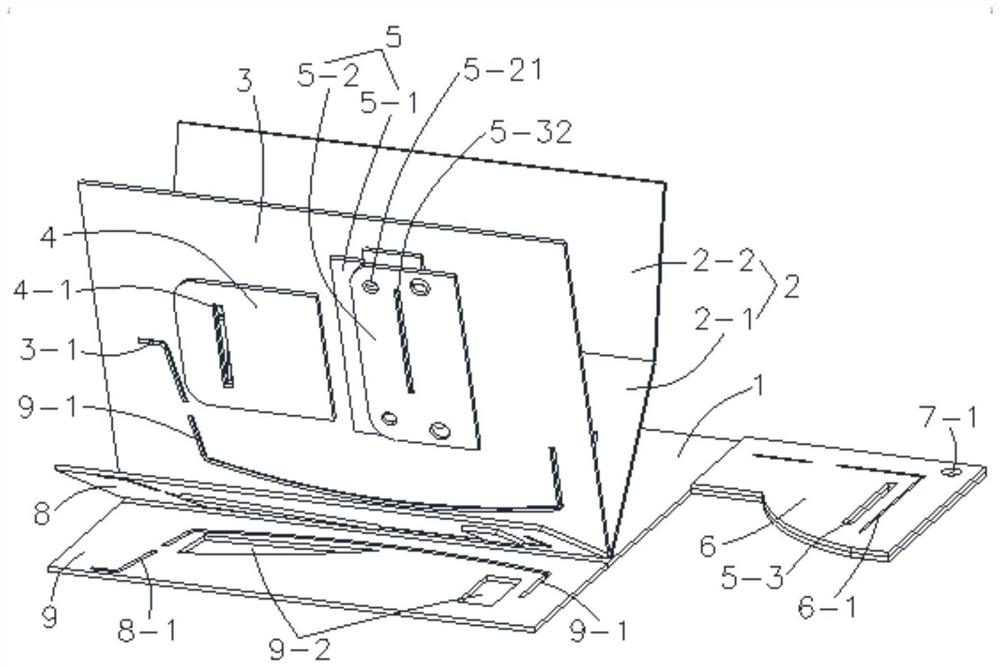

Combined template for sewing front piece of western-style clothes

PendingCN114836907AThe overall structure is simple and reliableSimple and reliable layoutWork-feeding meansStructural engineeringMechanical engineering

The invention belongs to the technical field of garment molds, and particularly relates to a suit front piece sewing combined template which comprises a main bottom plate, a chest dart plate and an inserted line bottom plate which are sequentially and movably arranged from bottom to top, the chest dart plate comprises a chest dart bottom plate and a chest dart cover plate, and the chest dart bottom plate and the chest dart cover plate are movably connected; the chest dart plate is formed when the chest dart cover plate and the chest dart bottom plate are unfolded, and a chest inserted line cover plate and a waist inserted line cover plate are sequentially and movably arranged above the inserted line bottom plate; the chest dart cover plate, the chest dart bottom plate and the main bottom plate are sequentially provided with chest dart line grooves in a penetrating mode, the chest embedded line cover plate, the embedded line bottom plate, the chest dart plate and the main bottom plate are sequentially provided with chest pocket embedded line grooves in a penetrating mode, and the waist embedded line cover plate, the embedded line bottom plate, the chest dart plate and the main bottom plate are sequentially provided with waist pocket embedded line grooves in a penetrating mode. The combined template has the advantages that sewing of the breast dart, the breast pocket inserted lines and the waist pocket inserted lines and splicing sewing of the front face and the front piece are ingeniously achieved on the combined template, operation is convenient and fast, production efficiency is improved, and production cost is reduced.

Owner:常州华利达服装集团有限公司

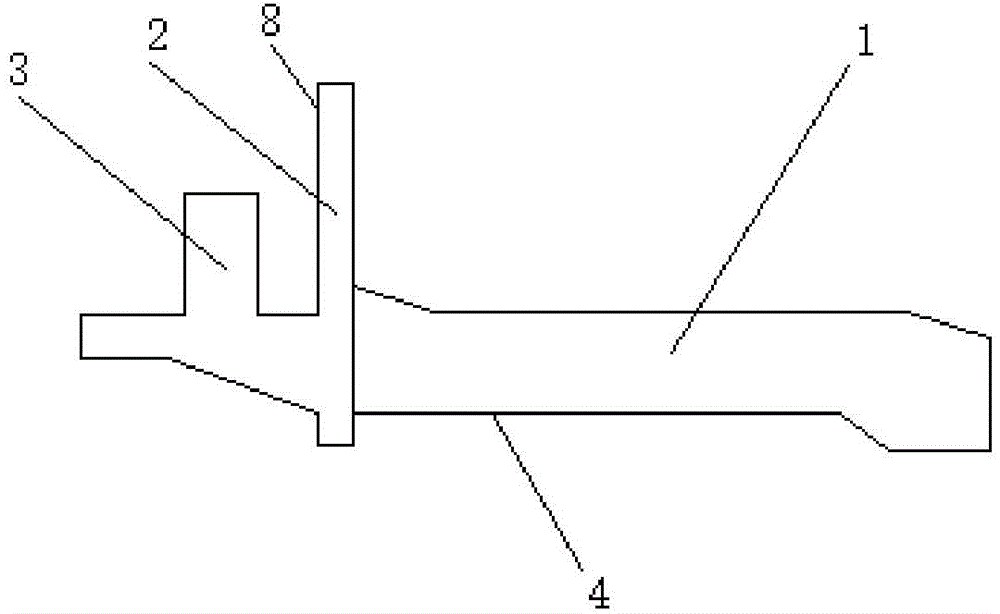

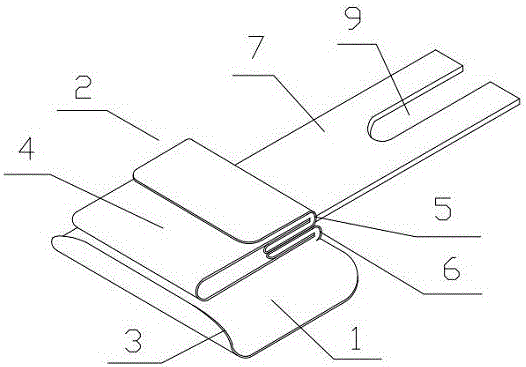

Cloth strip hemming auxiliary device

The invention discloses a cloth strip hemming auxiliary device and relates to the technical field of garment production. The main body of the device is a straight metal board which is trapezoid, the two sides of the trapezoid straight metal board are curved to be in the shape of a hook towards the same side, the shorter end of the straight metal board is connected with an installation board, and two strip-shaped sewing ports are formed in the installation board. The device has the advantages that the structure is simple, the design is novel, the hemming sewing points of a cloth strip are effectively guided by means of the trapezoid clamping board, sewing accuracy is high, production efficiency is high, using is convenient, practicality is high, and promotion is convenient to achieve.

Owner:蚌埠嘉怡景服装有限公司

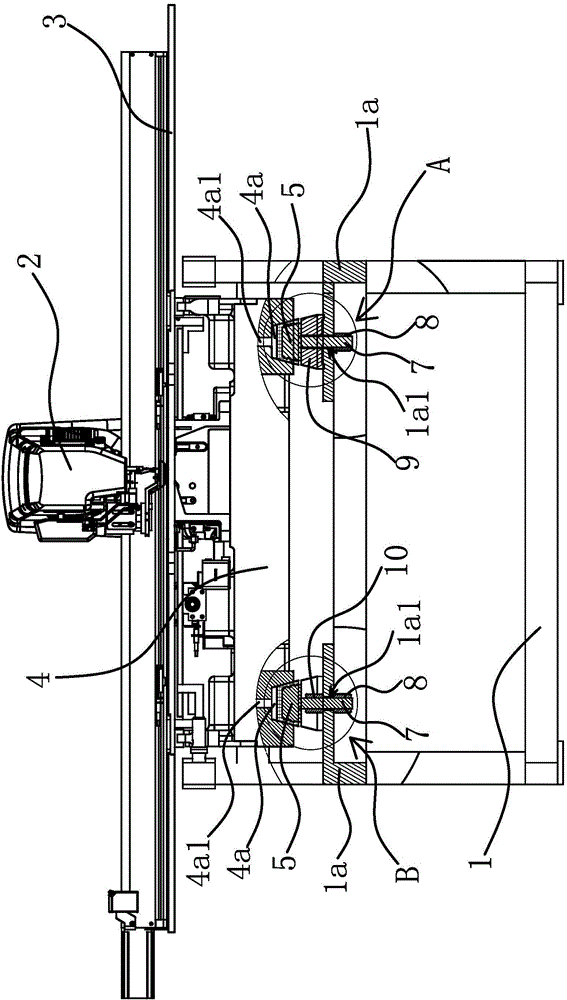

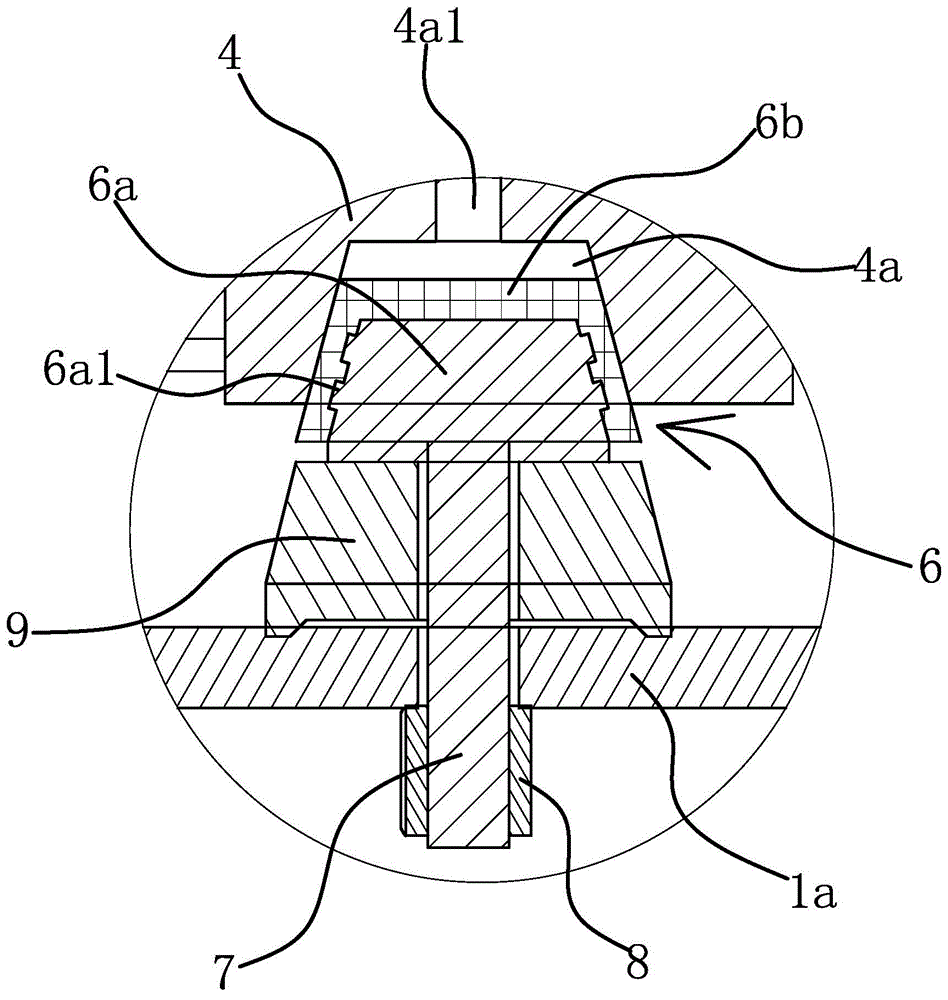

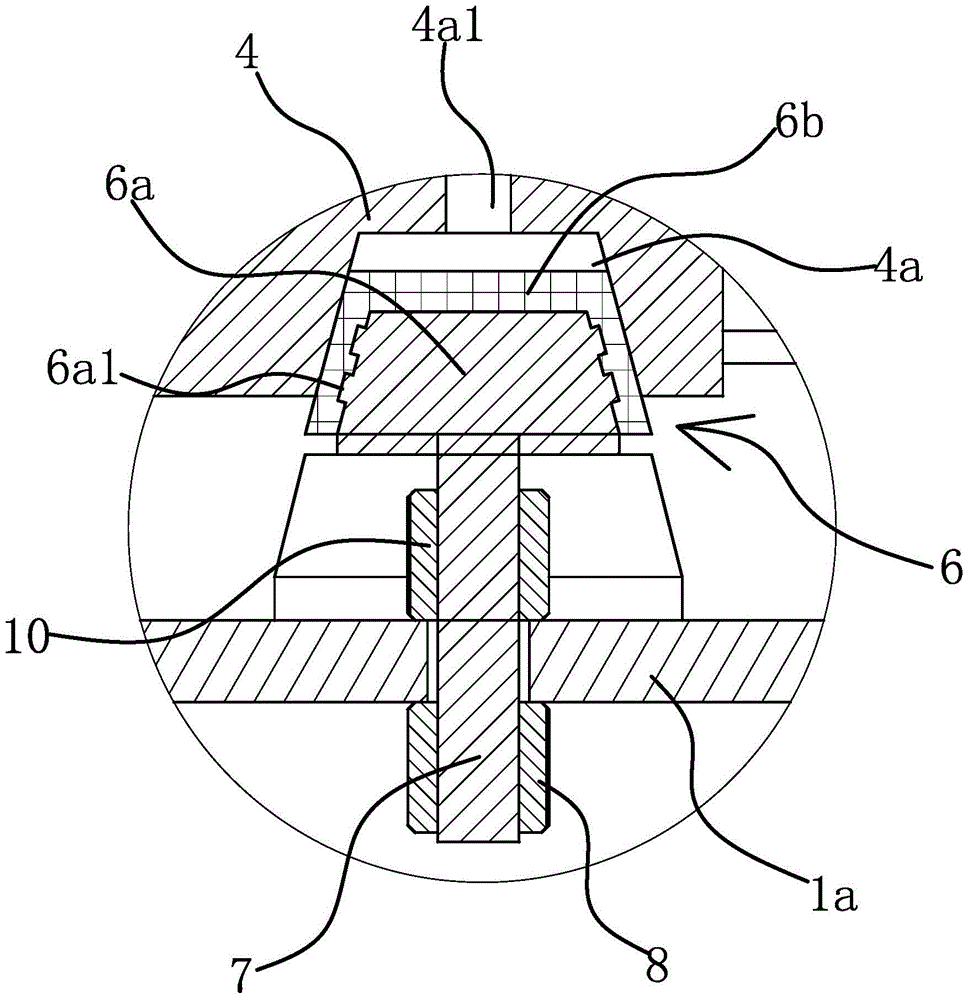

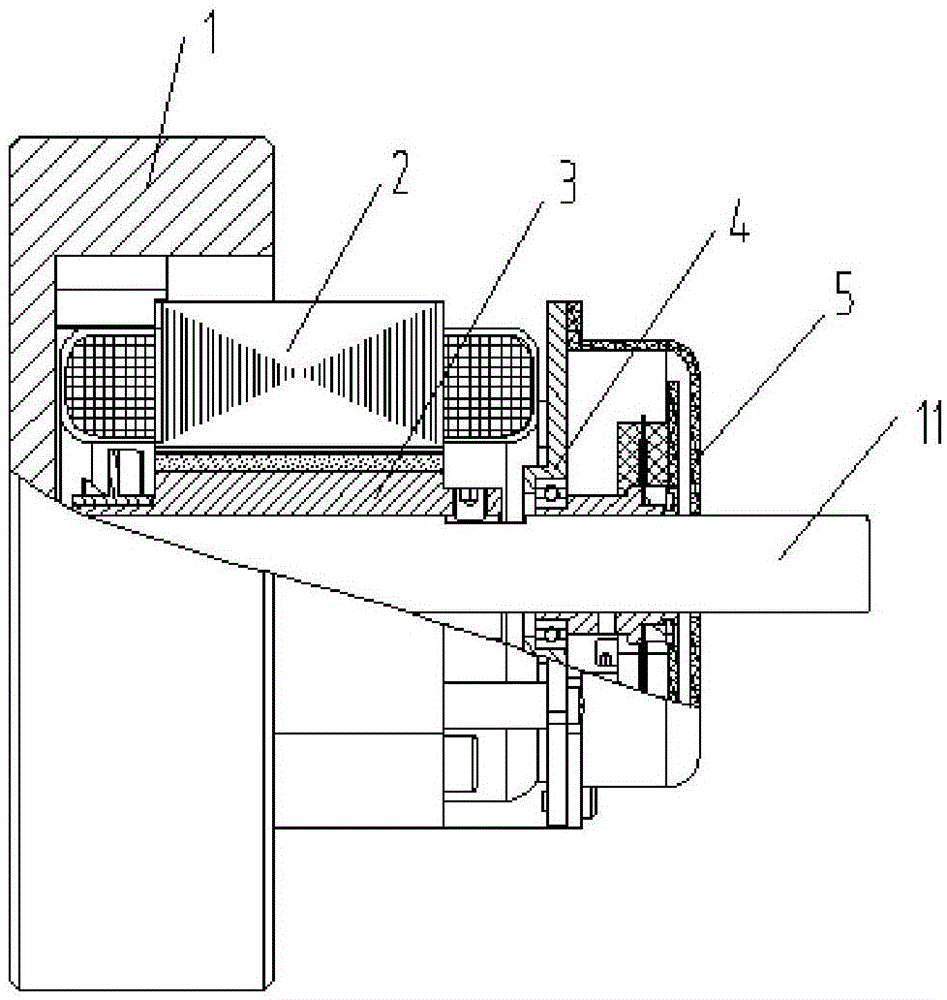

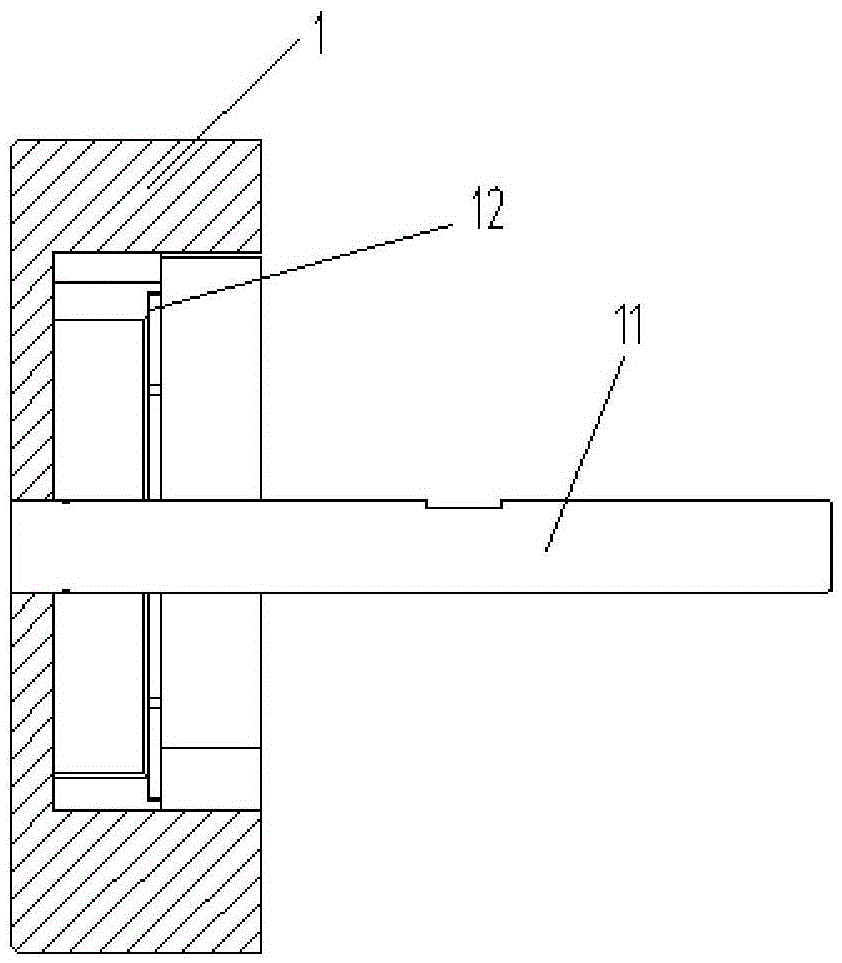

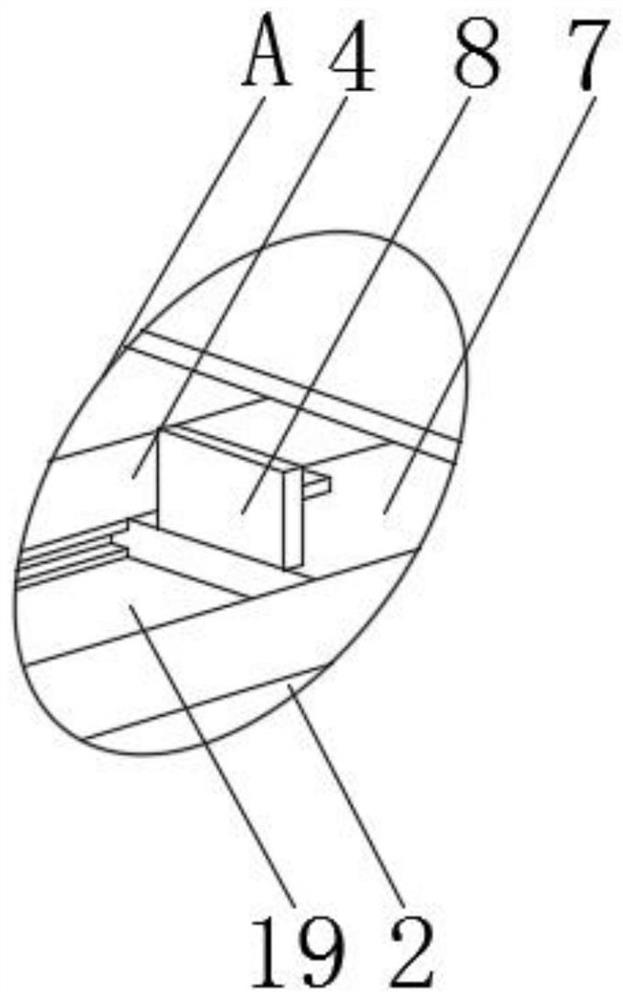

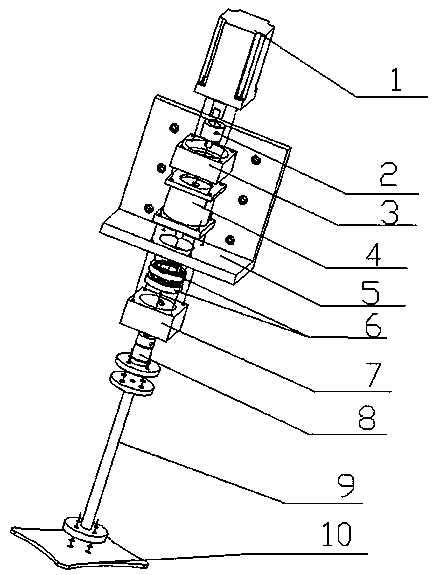

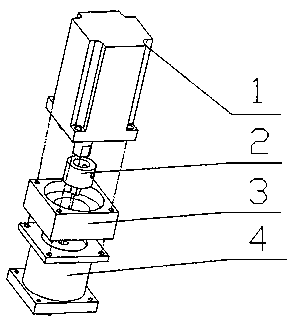

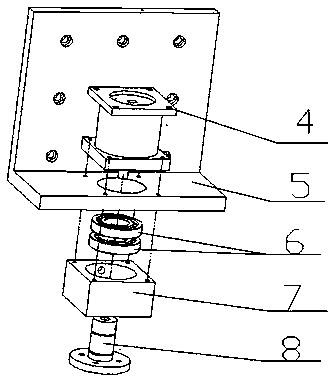

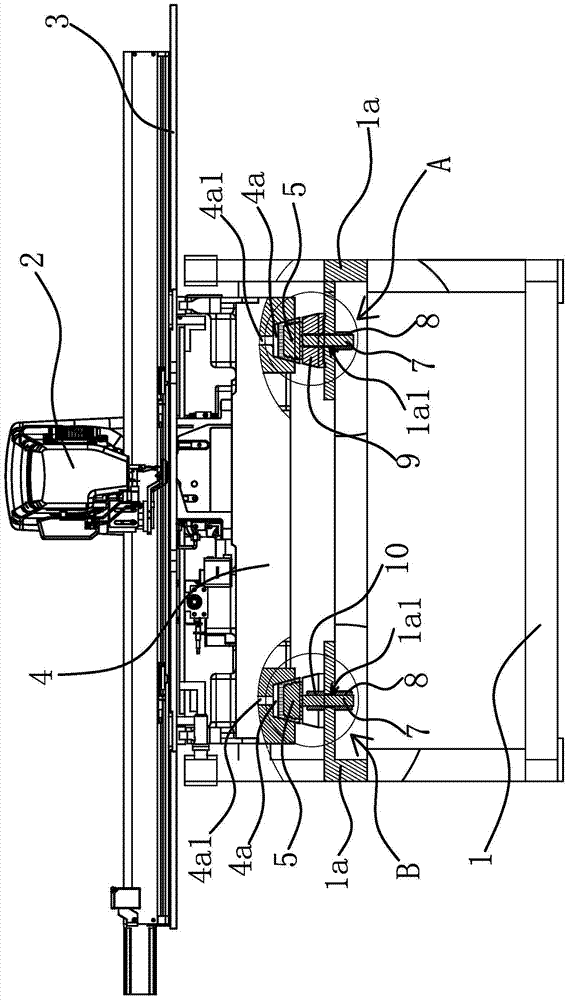

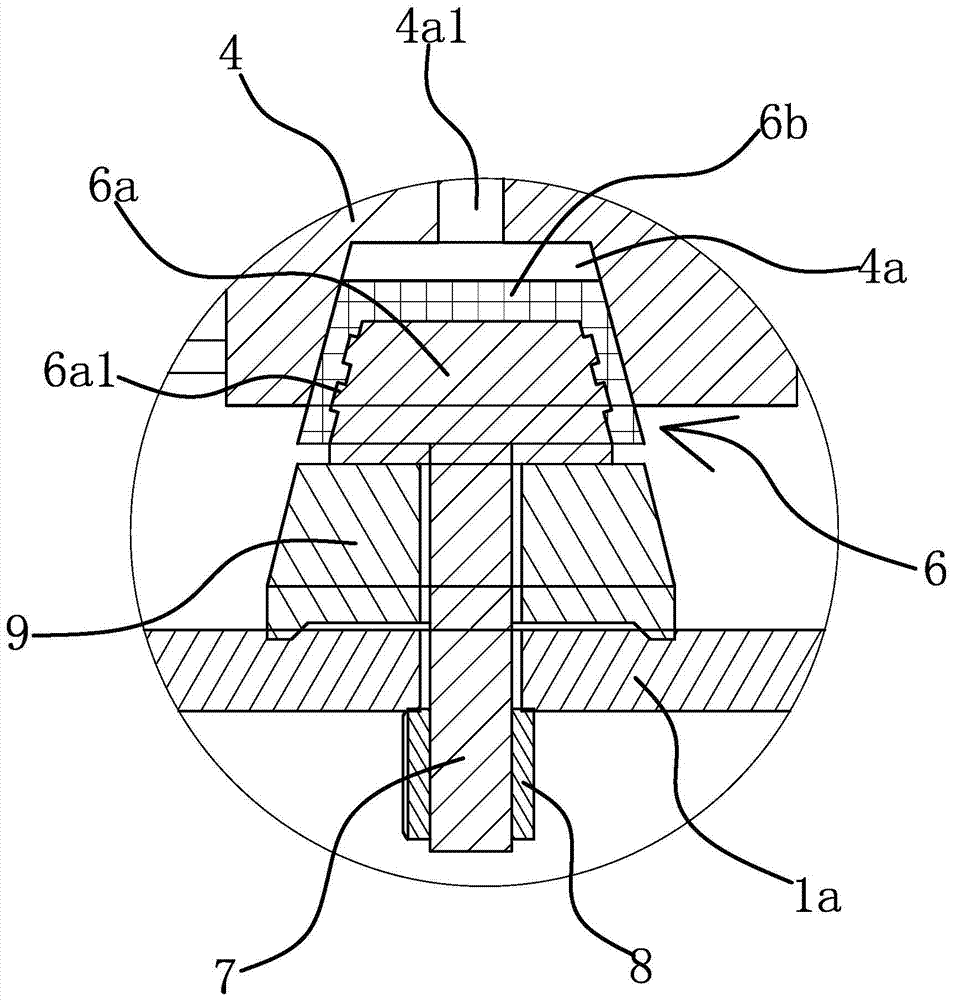

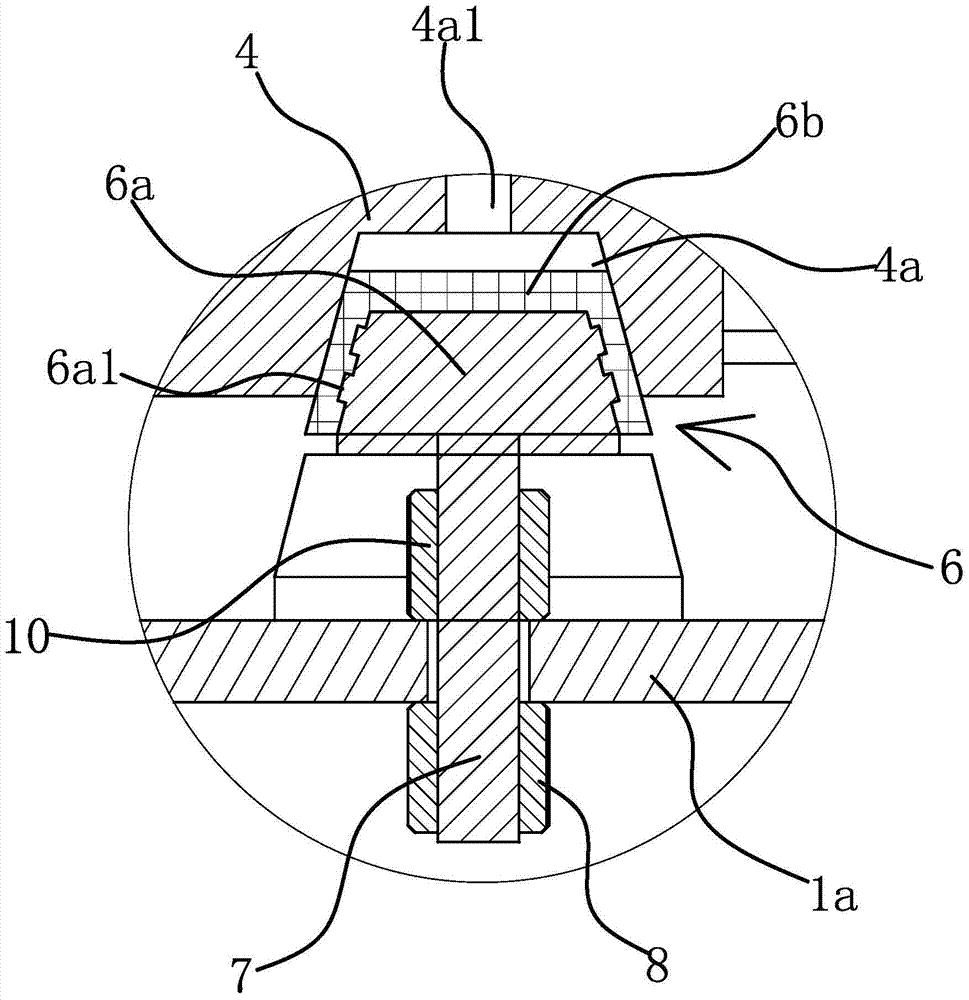

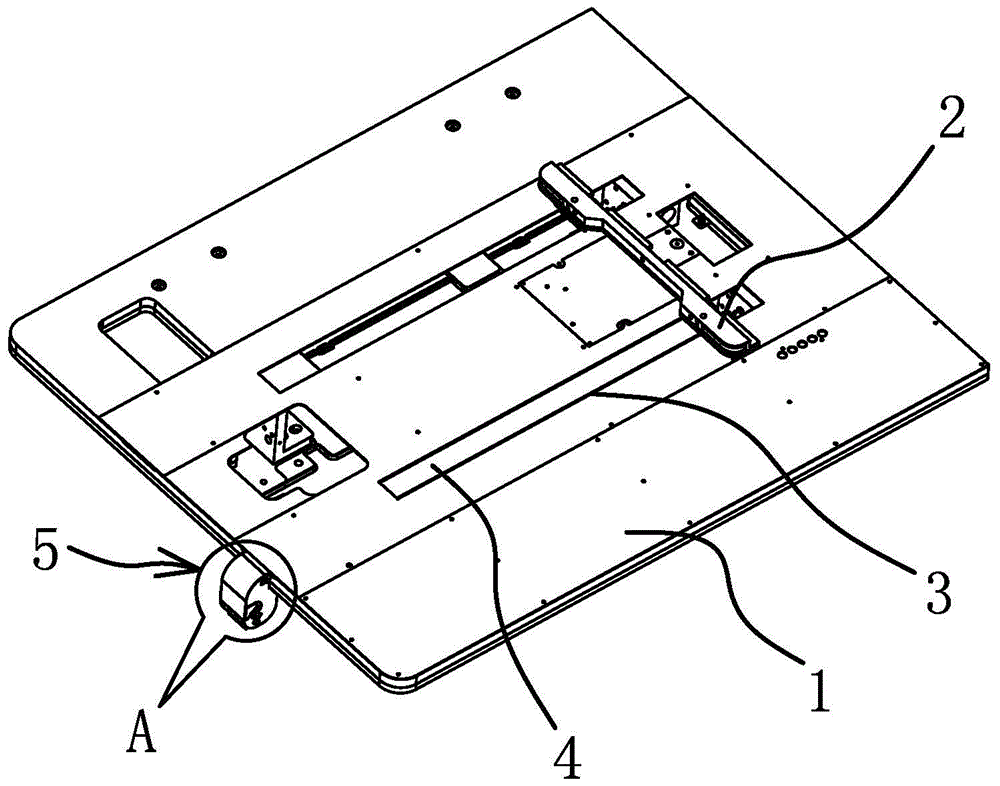

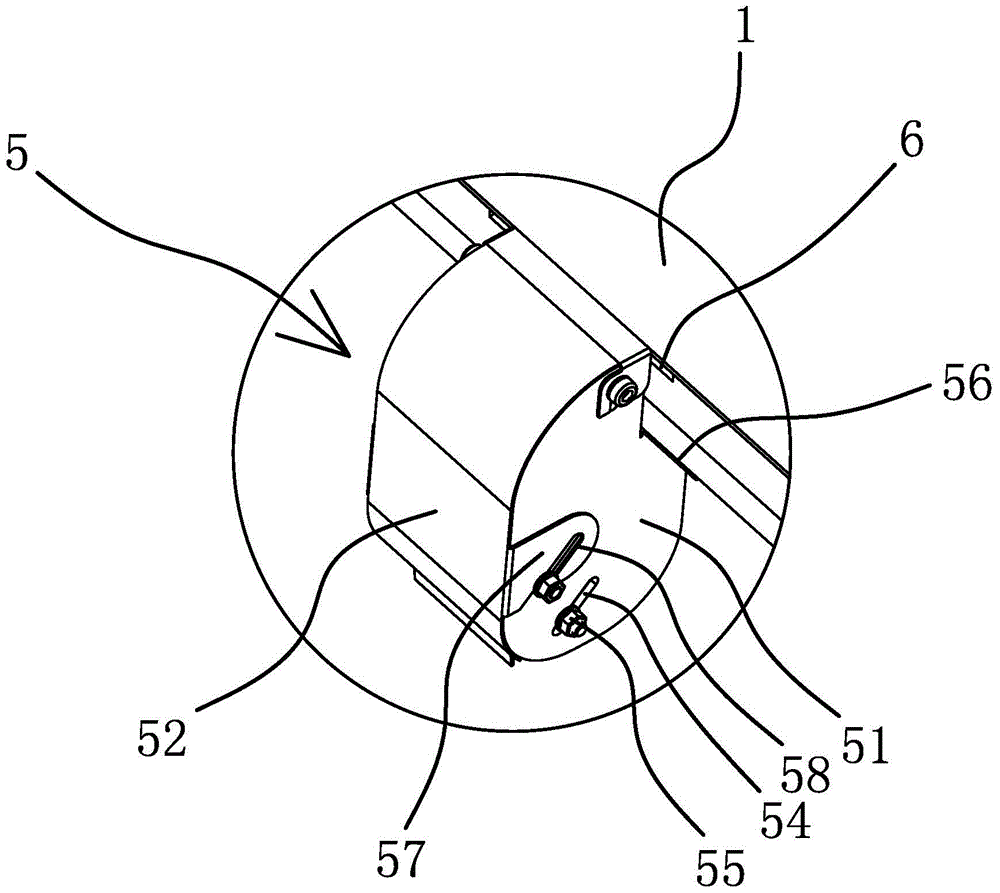

Head mounting structure for template sewing machine

ActiveCN104674474AEasy to replaceImprove sewing precisionSewing-machine elementsEngineeringMachining process

The invention provides a head mounting structure for a template sewing machine, and belongs to the technical field of sewing machines. The problem of noise produced by the vibration of a working bedplate and a rack of a conventional template sewing machine is solved. The head mounting structure for the template sewing machine comprises a base in a rack, wherein a head is fixedly arranged on the base, and extends from the upper surface of a working bedplate; a support part positioned below the base is arranged on the rack; a plurality of support cushion blocks are arranged between the base and the support part; each support cushion block is positioned on the support part, and elastically contacts with the base. According to the head mounting structure for the template sewing machine, the head is fixedly arranged on the base, and then the base is arranged on the rack through the support cushion blocks to realize floating connection between the head and the rack, so that the working bedplate of the template sewing machine is more stable in a machining process, and the sewing accuracy of the template sewing machine is improved.

Owner:浙江耐拓机电科技有限公司

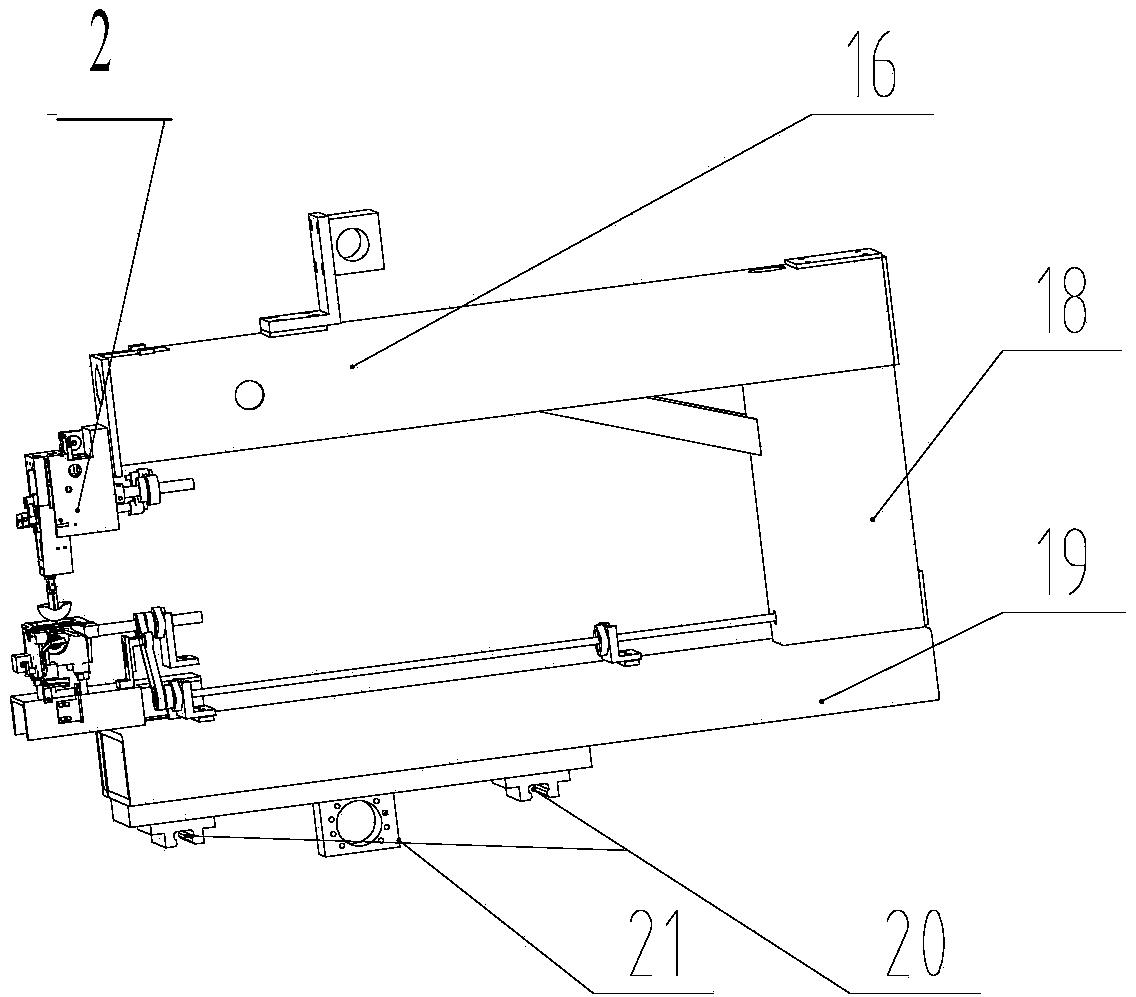

Dual-lead-screw synchronous drive zero-latency full-automatic single-end sewing machine

InactiveCN106149208ARun lightSmooth runningWork-feeding meansSewing-machine control devicesControl engineeringEngineering

The invention discloses a dual-lead-screw synchronous drive zero-latency full-automatic single-end sewing machine which comprises a bridge-type frame rack, a platen located below a rack crossbeam in the middle of the rack, a rack crossbeam X-direction guide rail, a Y-direction working set A located on the tabletop, a Y-direction working set B, a Y-direction driving device, a machine head assembly, an X-direction lower transmission lead screw, an X-direction transmission lead nut, an X-direction sliding guide rail, an X-direction upper transmission lead screw and a synchronous belt. The rack crossbeam X-direction guide rail and the X-direction upper transmission lead screw are installed on the rack crossbeam in the X direction. The synchronous belt is located on one side of the rack to be connected with the X-direction upper transmission lead screw and the X-direction lower transmission lead screw, and synchronous rotation of the X-direction upper transmission lead screw and the X-direction transmission lead screw is ensured. The dual-lead-screw synchronous drive zero-latency full-automatic single-end sewing machine is operated slightly in the X direction, stable and reliable in operation, good in rotating shuttle and machine head synchronism, strong in generality, free of vibration, high in sewing precision, and low in installation and maintenance difficulty.

Owner:上工富怡智能制造(天津)有限公司

A control method and equipment for seaming centering of thin strip steel in continuous annealing furnace

ActiveCN105618596BReduce the risk of belt breakageImprove sewing precisionMetal-working feeding devicesMetal working apparatusStrip steelEngineering

Owner:BAOSHAN IRON & STEEL CO LTD

A sewing method for sleeve and shoulder joints

ActiveCN110373821BGuaranteed sewing qualityAvoid unclosedSewing apparatusCross connectionEngineering

Owner:GUANGDONG JIN YUE LAI AUTOMATION EQUIP CO LTD +1

Automatic edge sealing device for imitated rattan plaited chair cushion

ActiveCN114134650ANeat and beautiful seamsAvoid deformationWorkpiece carriersWork-feeding meansEngineeringChair cushion

The invention relates to an automatic edge sealing device for a rattan-imitated chair cushion, and the device comprises a control mechanism which comprises a pressing assembly and a rotating assembly; the cutting mechanism comprises a slitting assembly and a first transmission assembly; a sewing mechanism; the discharging mechanism comprises a lifting assembly arranged on the operation table, a second transmission assembly which is in synchronous transmission with the downward pressing assembly and is used for driving the lifting assembly to move in the vertical direction, and a limiting assembly which is installed on the operation table and is used for controlling the lifting assembly to automatically rotate for discharging; the cutting-off mechanism is used for automatically cutting off the edge sealing strips of the group of bolsters subjected to edge sealing; the rattan chair bolster sewing machine solves the technical problems that in the rattan chair bolster production process, the peripheral hems of the bolster are manually sewn, the edge cutting work of hemming strips and the rotation work of the bolster need to be completed with one hand, misoperation is prone to occurring, the speed is low, and the production efficiency is low.

Owner:ANHUI DAIJIA CRAFT CO LTD

Middle seat of sewing machine

InactiveCN106149228AHigh transmission precisionImprove sewing precisionSewing-machine control devicesDesign technologyEngineering

The invention discloses a middle seat of a sewing machine, and belongs to the technical field of design of sewing machine parts. The middle seat comprises a mounting plate, a shell and a clamping seat, wherein the whole middle seat of the sewing machine is obtained by casting; the clamping seat is located on the left side of the mounting plate, and a gap is reserved between the clamping seat and the mounting plate; the shell is located on the right side of the mounting plate; the clamping seat, the mounting plate and the shell form a whole; the upper surface of the shell is a casting surface and does not need to be machined; both the bottom surface and the side surface of the shell are combination surfaces, so that the precision requirement is high, and the bottom surface and the side surface need to be milled and formed on a milling machine. According to the middle seat of the sewing machine, the transmission precision of the sewing machine can be improved favorably, and the phenomenon that the sewing machine is blocked by impurities, such as thread ends and shreds, entering the sewing machine in a sewing process is effectively prevented; an enough space for accommodating transmission parts is reserved in the shell, and no interference with other components of the sewing machine is avoided; all the parts in the shell have enough high shape and position precision.

Owner:CHIZHOU TAISHENG SEWING MACHINERY TECH CO LTD

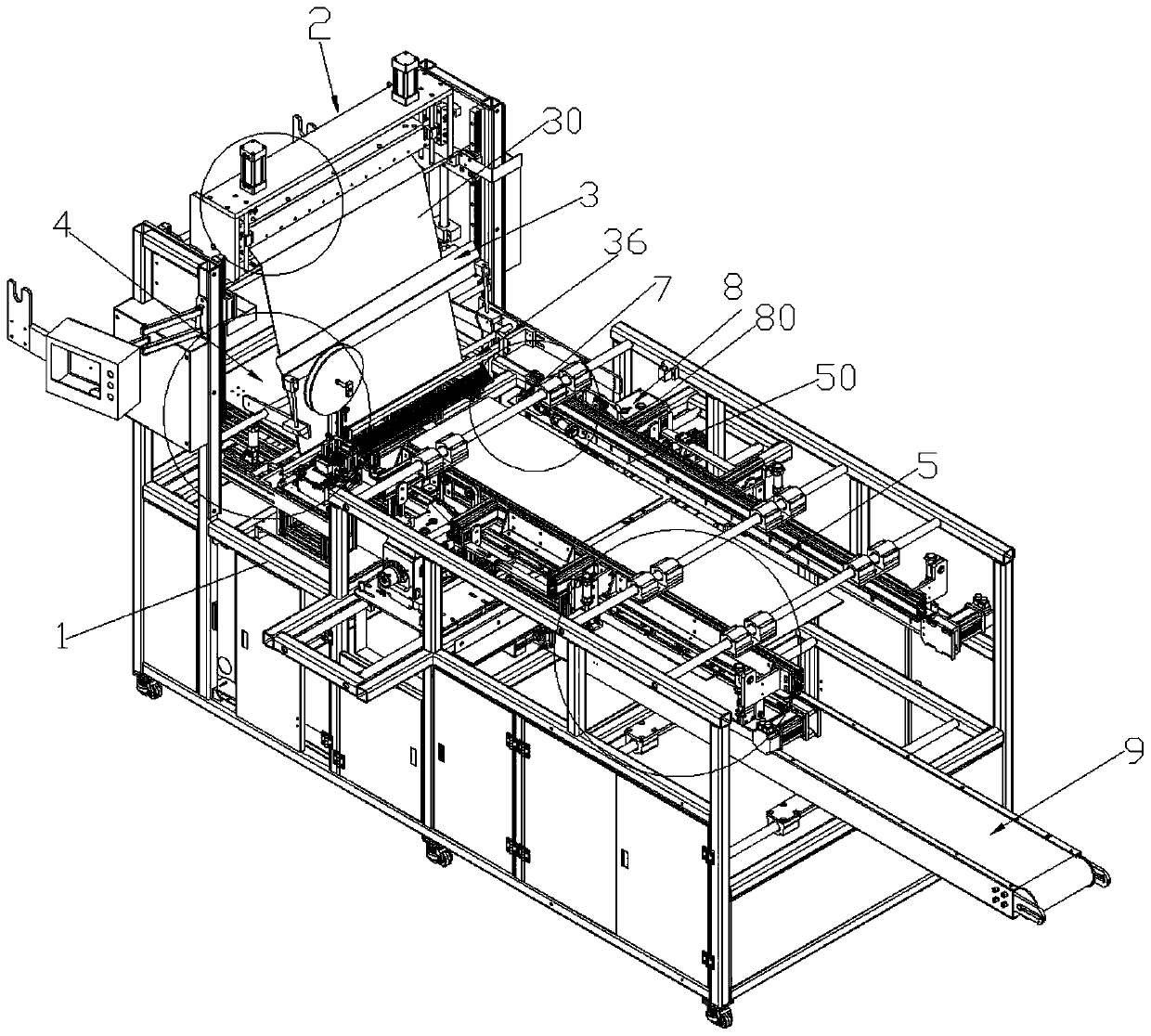

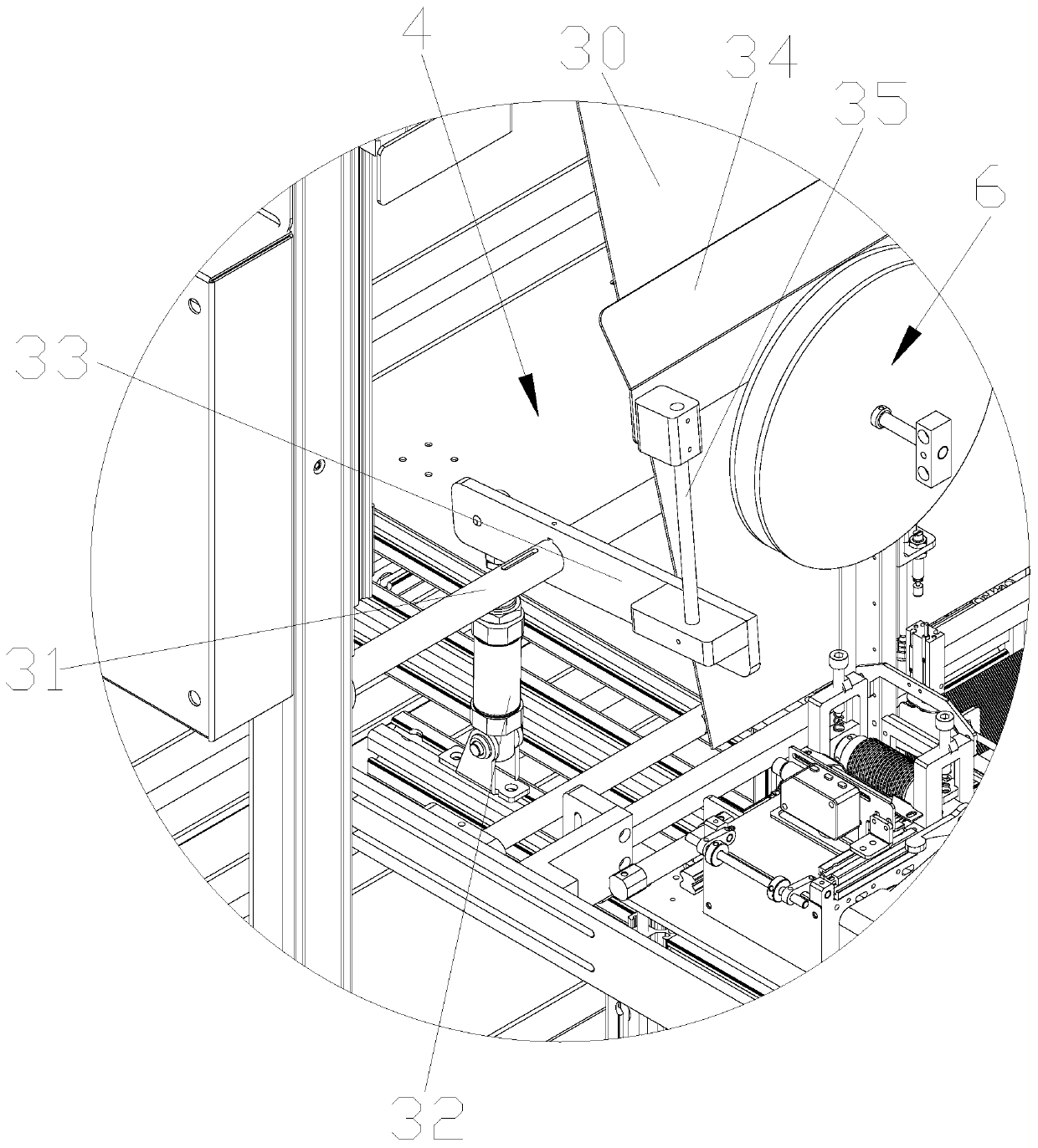

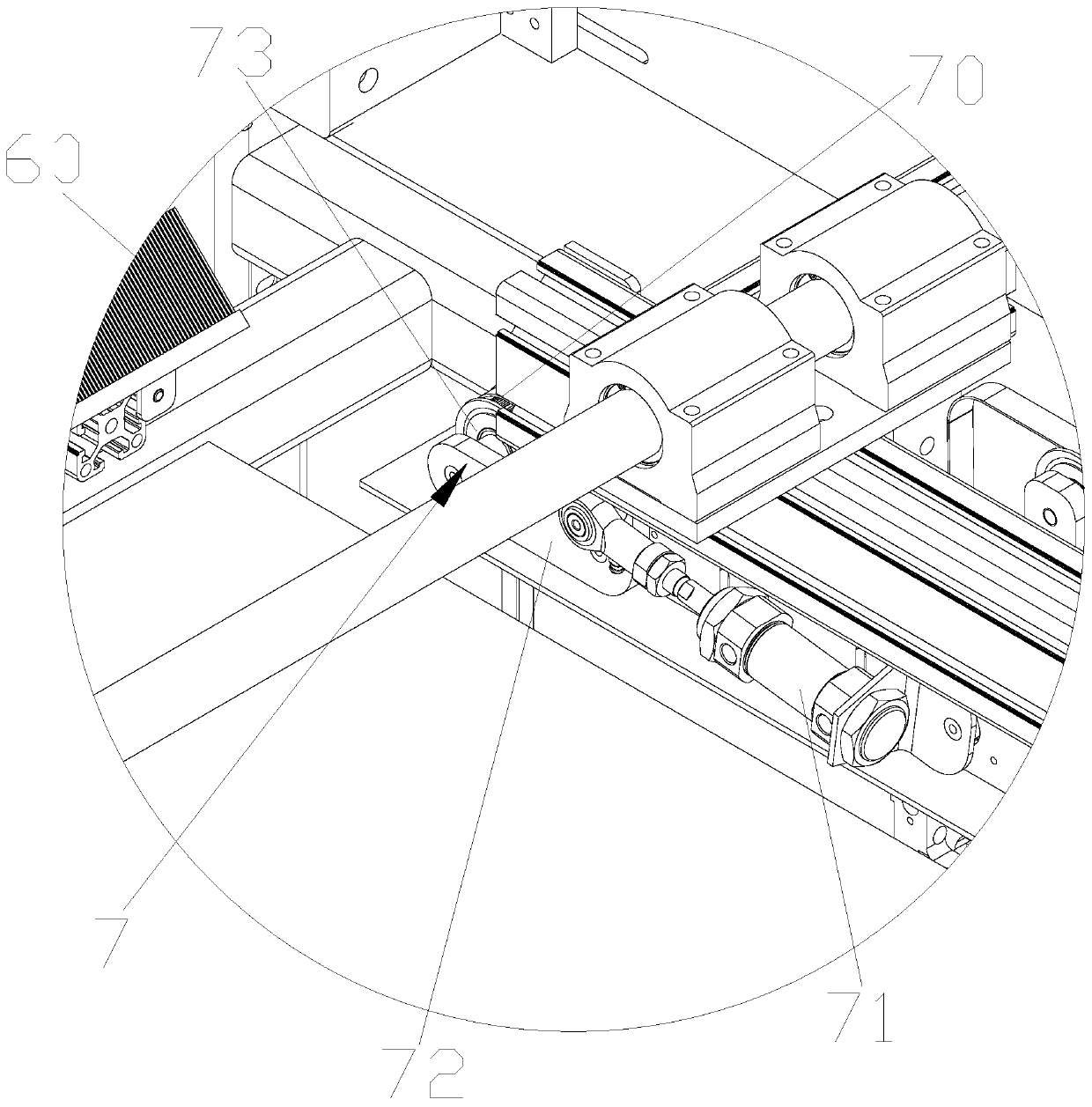

Full-automatic pocket machine

PendingCN110230154ACompact structureIncrease productivityWorkpiece carriersWork-feeding meansEngineeringConveyor belt

The invention relates to a full-automatic pocket machine. A pressing assembly is arranged at the back end of a cloth cutting assembly; a cloth folding assembly positioned below the cloth cutting assembly is arranged at the front end of the pressing assembly; a conveying platform is arranged at the back end of the pressing assembly; a feeding machine is arranged at the front end of the conveying platform; two oppositely arranged cloth conveying mechanisms are arranged on the conveying platform; a sewing machine assembly positioned on one sides of the cloth conveying mechanisms is arranged on the conveying platform; the conveying platform consists of a first conveying platform and a second conveying platform which are sequentially arranged; the second conveying platform consists of two rotating plates rotatably arranged on the machine frame; a synchronous wheel conveyor belt is arranged below the conveying platform. The full-automatic pocket machine is compact in structure; the full-automatic pocket machine can automatically complete cutting and opposite folding of cloth as well as sewing of the two sides of the cloth after oppositely folding and finally conveys out the cloth throughthe synchronous wheel conveyor belt; a whole process is automatically completed through a machine, so that the production efficiency is high and the sewing precision is high; meanwhile, a small number of workers are used, so that the production cost is reduced; batch production and processing requirements are met.

Owner:SUZHOU TRANSPARENT TECH CO LTD

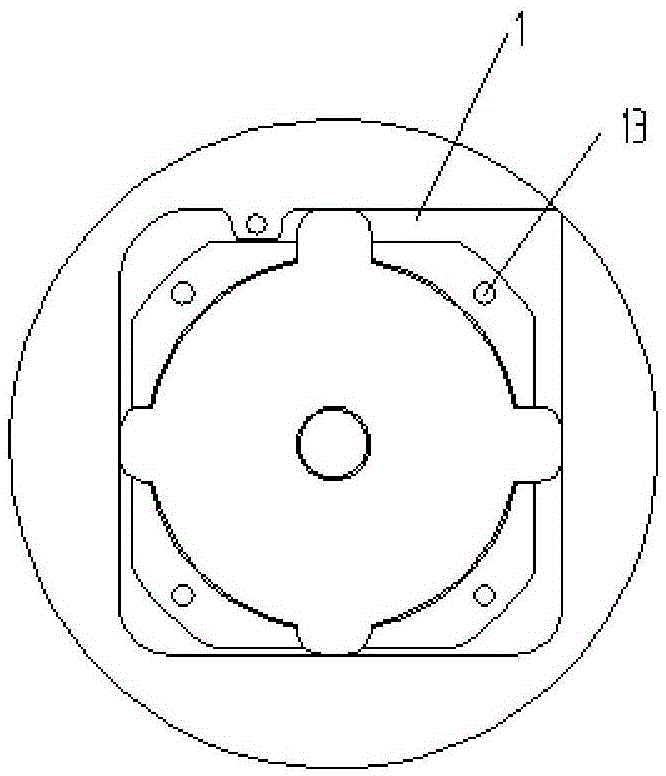

Motor of stator and rotor split type for sewing machine

ActiveCN105099008AReduce axial sizeReduce load inertiaMagnetic circuit rotating partsMagnetic circuit stationary partsGratingEngineering

The invention discloses a motor of a stator and rotor split type for a sewing machine, and the motor is connected with the head of the sewing machine. The motor comprises a stator, a rotor, an integrated coder, and a rear cover, wherein the rotor is a hollow shaft. The rotor, the integrated coder and the rear cover are sequentially fixed on a sewing machine main shaft in the head of the sewing machine in a coaxial and sleeved manner. The stator is fixedly connected with the head of the sewing machine. The integrated coder is connected with a needle rod of the sewing machine, and can control the angle of the needle rod of the sewing machine. A coder seat is provided with a coder installation column with adjustable height. An optical grating assembly comprises an optical grating support, an optical grating sheet, an optical grating pressure ring, and a clamping spring, wherein the optical grating support is coaxially disposed on the sewing machine main shaft in a sleeved manner, and can be rotated and fixed. After the above structure is employed, the motor is small in axial size, can save the space, is small in load inertia, and is high in sewing speed. The stator or the rotor can serve as an independent part of the sewing machine, and the motor is small in temperature rise, and is low in noise. Meanwhile, the angle of the needle rod of the sewing machine can be controlled according to the needs, and the motor is convenient in operation, and is high in sewing precision.

Owner:JIANGSUSNGQI GROUP

Disposable internal incision and closure stapler

ActiveCN104224259BEasy to holdPrecise movement controlDiagnosticsSurgical staplesBiomedical engineeringLeft handed

The invention relates to the technical field of disposable anastomats, in particular to a disposable internal opening cutting and enclosing anastomat. The disposable internal opening cutting and closing anastomat comprises a cutting molding assembly, a transmission assembly and a gun body provided with a triggering assembly, wherein the cutting molding assembly comprises a nail cabin bracket, a scalpel support ring, a nail pressing seat, a nail pushing device, a nail cabin support and a nail cabin; the nail cabin is clamped in a clamping groove of the nail cabin support through a buckle; the nail cabin support is directly connected with the gun body through the transmission assembly; the head of the nail cabin is circular-arc-shaped or parabolic; nail grooves of the nail cabin are of asymmetrical mode; the transmission assembly comprises a transmission lead screw; the lead screw is a large-screw-pitch left-handed lead screw; the tail end of the lead screw is connected with a corresponding lengthened nut assembly; the lengthened nut assembly and a knob positioned at the tail end of the gun body are molded together by injecting or embedded together; the gun body is a lever type or connecting-rod-type gun body. The disposable internal opening cutting and enclosing anastomat is skillful in design, and has a good application prospect; by adopting the disposable internal opening cutting and enclosing anastomat, a plurality of use problems in the prior art can be solved effectively.

Owner:JIANGSU QIANJING MEDICAL EQUIP

An automatic bag sticking machine

ActiveCN113308806BHigh degree of automationEasy to controlWork-feeding meansPressersControl systemSoftware engineering

Owner:WENZHOU GUTAI MACHINERY TECH CO LTD

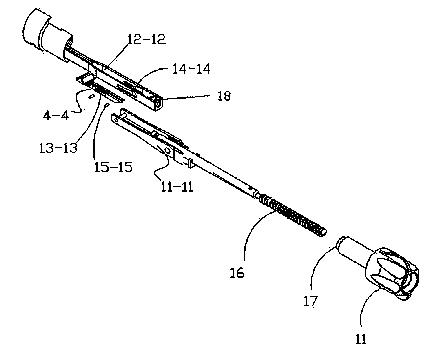

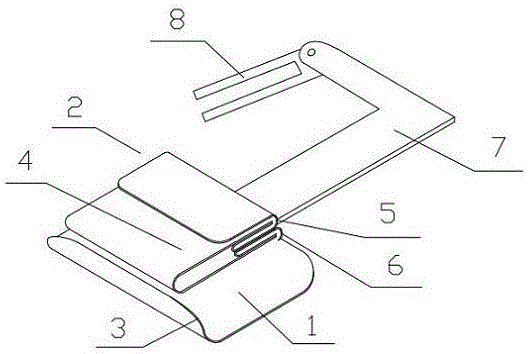

Special needle for hernia surgery under laparoscope

The invention discloses a special needle for a hernia surgery under a laparoscope. The special needle comprises a grip, wherein an air cylinder mounting cavity is formed in the grip; a needle tube is arranged at the end part of the air cylinder mounting cavity; a claw hook is arranged in the needle tube; an air cylinder is arranged in the air cylinder mounting cavity; a controller is arranged on the air cylinder; a switch is arranged on the controller of the air cylinder; a trigger is arranged on the switch; control rods are arranged on the two sides of the trigger respectively; the trigger is fixed to a fixed column; a pushing rod is arranged on the air rod of the air cylinder; and the claw hook is fixed to the end, away from the air cylinder, of the pushing rod. Compared with the prior art, the special needle has the advantages that suturing by human hands or traditional surgical tools can be replaced along with small wounds and high suturing precision; the distance during operation can be accurately grasped by means of a graduated scale; the full-mechanical structure is very convenient to use, can stretch and retract, and is unlike traditional manual stretching and retracting; and the stability can be greatly improved by matching with a fixed support. The special needle has a good market prospect.

Owner:宁德市闽东医院

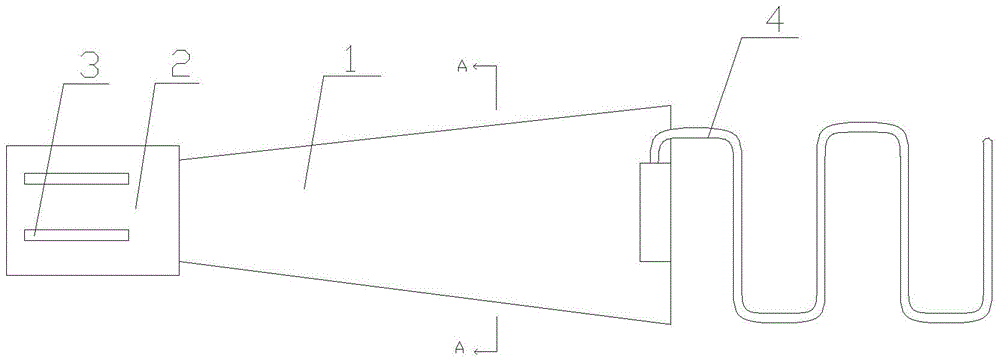

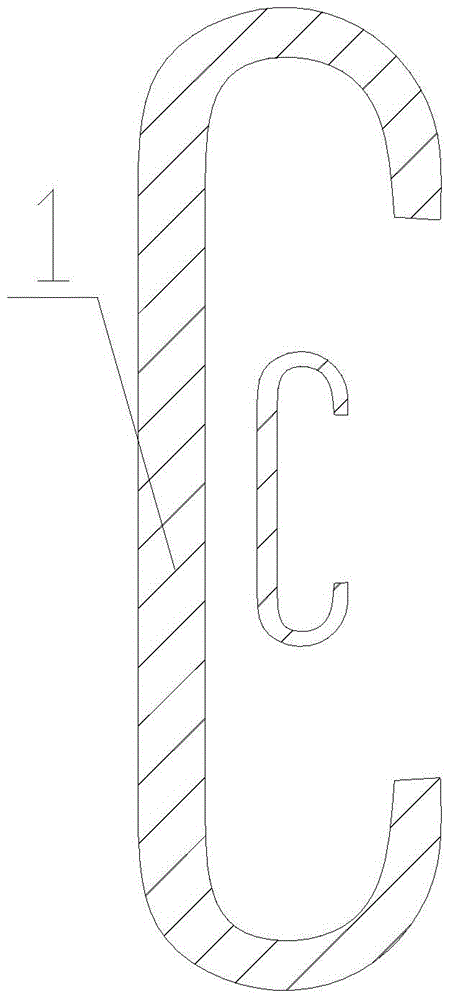

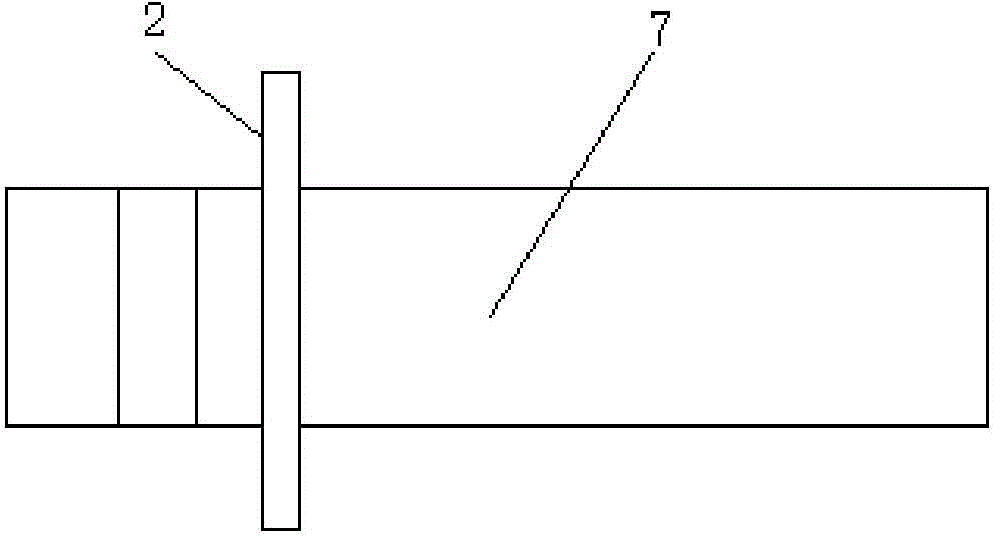

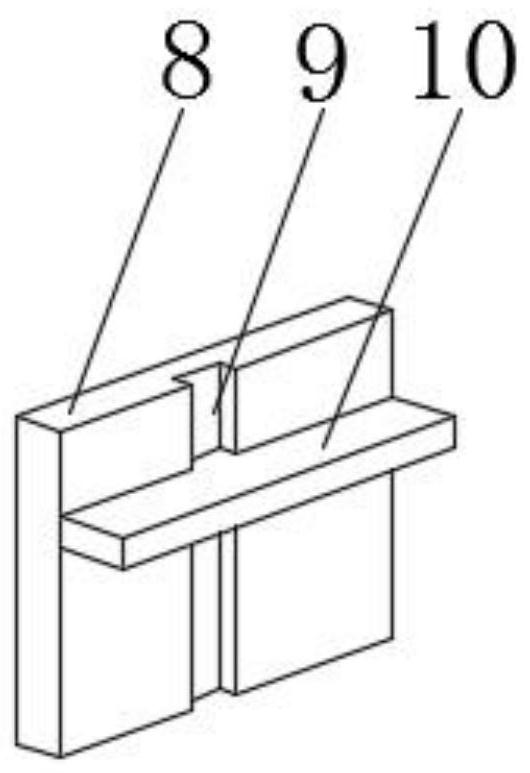

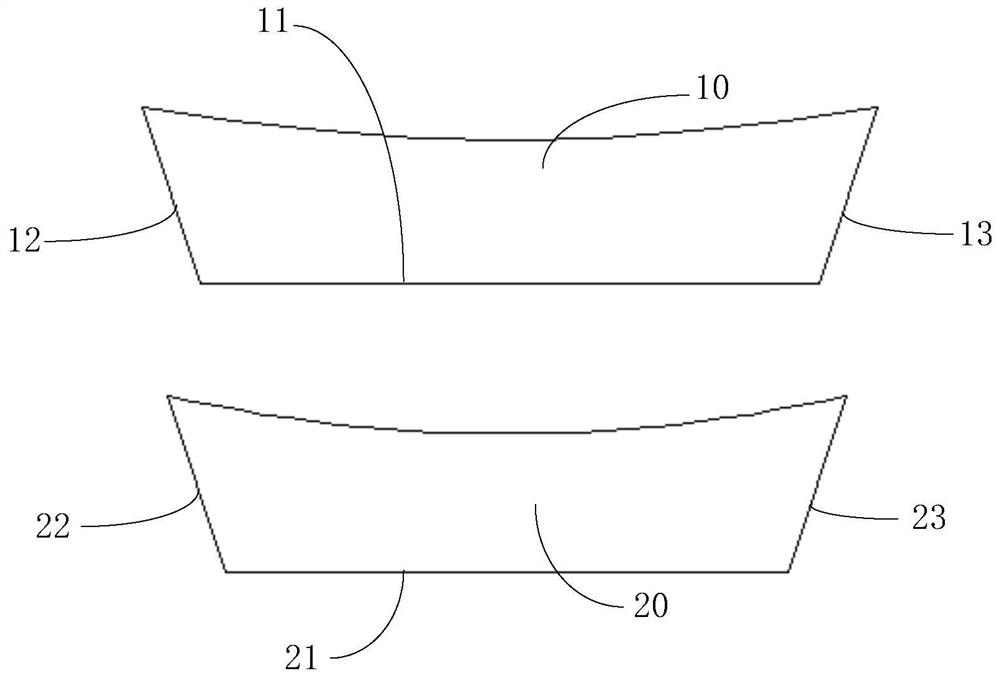

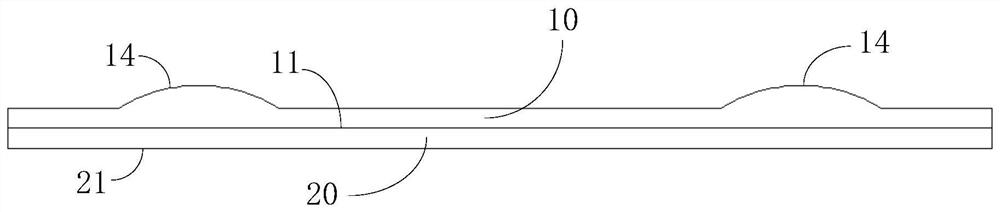

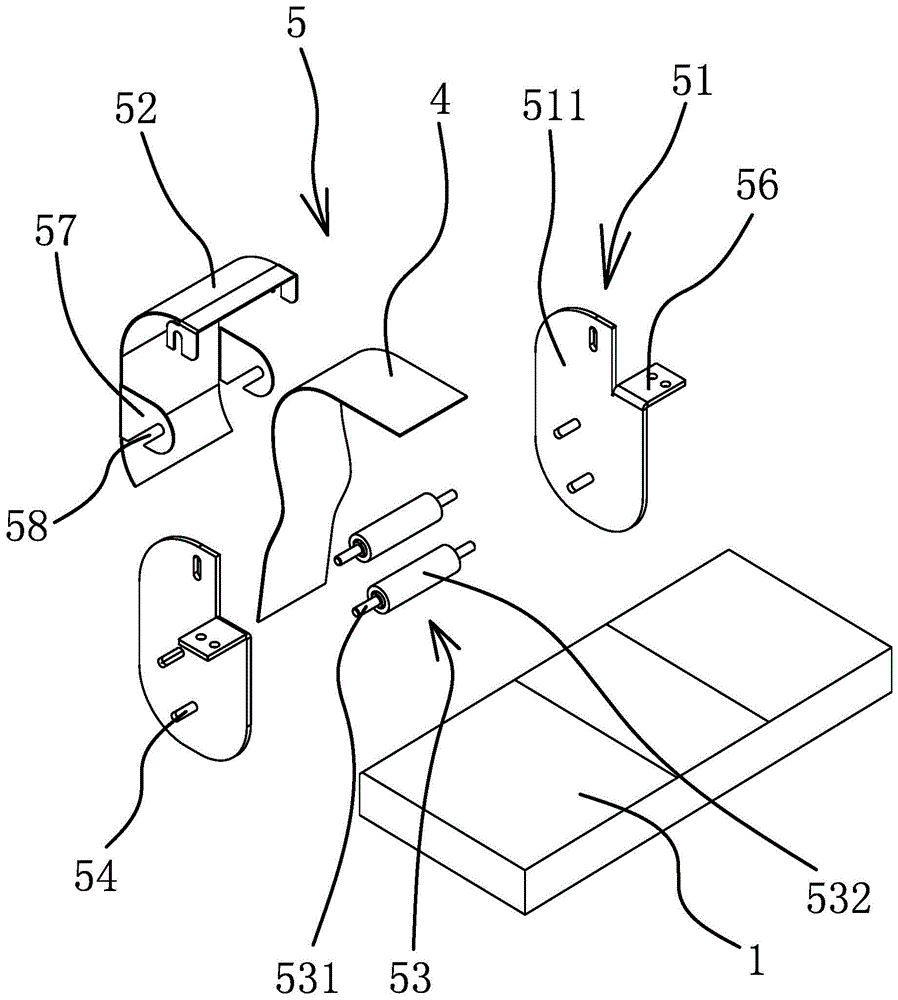

A mold for sewing back belts

The invention discloses a mold for sewing a back waist band, and relates to the technical field of sewing machines. The mold comprises a first guiding piece and a second guiding piece, the first guiding piece comprises a base plate, a semi-U-type hook with a rightward opening is arranged on the left side of the base plate, the second guiding piece comprises a support, the upper face of the support is provided with an upper U-type hook with a leftward opening, the lower face of the support is provided with a lower U-type hook with a leftward opening, and a lower half U-type hook body of the lower U-type hook is fixed on the base plate. The mold is simple in structure and low in manufacturing cost, the steps of ironing, seam reversing, seam allowance and the like are omitted, an open thread is directly sewed, the sewing quality can be guaranteed, the sewing speed is greatly quickened, and the work efficiency is greatly improved.

Owner:JIHUA 3534 CLOTHING

A garment template machine

ActiveCN109468760BEasy to storeEasy to retractWork-feeding meansMechanical engineeringWork productivity

The invention discloses a clothing manufacturing template machine which comprises a template machine base. A working table is fixed to the outer surface of the top end of the template machine base through bolts. Guide grooves are formed in the positions, close to the two sides, of the outer surface of the top end of the working table respectively. A movable plate is movably installed on the innersurface of each guide groove. A control box is fixed to the position, close to the center, of the outer surface of the top end of the working table through bolts. By means of the clothing manufacturing template machine, tools can be more conveniently stored; meanwhile, a placement box can be stored, and the space is prevented from being occupied; the placement box can be more freely and rapidly moved, the activity range of workers is enlarged, the clothing manufacturing template machine can be more conveniently used by workers, and work efficiency is improved; a template shell can be better fixed, it is avoided that the template shell and inner clothing slide relatively during sewing, the sewing precision is better improved, and better use prospects are achieved.

Owner:阜阳鑫合服饰有限公司

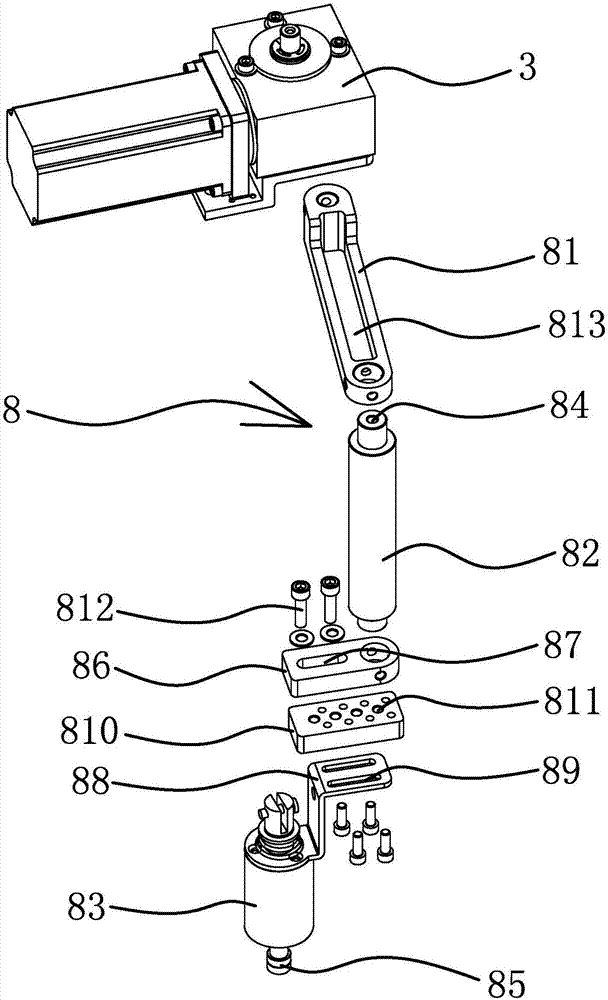

Cloth pressing and rotating mechanism of full-automatic sewing unit

PendingCN111041719ASimple mechanical structureGuaranteed uptimePressersInterference fitPillow block bearing

The invention relates to the technical field of sewing equipment, in particular to a cloth pressing and rotating mechanism of a full-automatic sewing unit. The purpose is to solve the problems of lowefficiency and poor precision of manual control of rotary sewing in the prior art. According to the technical scheme, the mechanism comprises a speed reducer mounting seat; a speed reducer and a motorseat are arranged on the upper surface of the speed reducer mounting seat in sequence from bottom to top; a motor is connected to the motor seat; a shaft sleeve is in the step column shape; the largediameter end of the shaft sleeve is fixedly arranged on a shaft of the motor; the small diameter end of the shaft sleeve is arranged in the motor seat and is in transition fit with a gear sleeve of the speed reducer; the lower surface of the speed reducer mounting seat is connected with a bearing seat; a bearing is in interference fit with the interior of the bearing seat; a connecting sleeve isin interference fit with the bearing and is fixed on the shaft of the speed reducer; a connecting rod is fixed to the lower surface of the connecting sleeve; and a cloth pressing plate is fixedly arranged at the bottom of the connecting rod.

Owner:XIAN TYPICAL IND

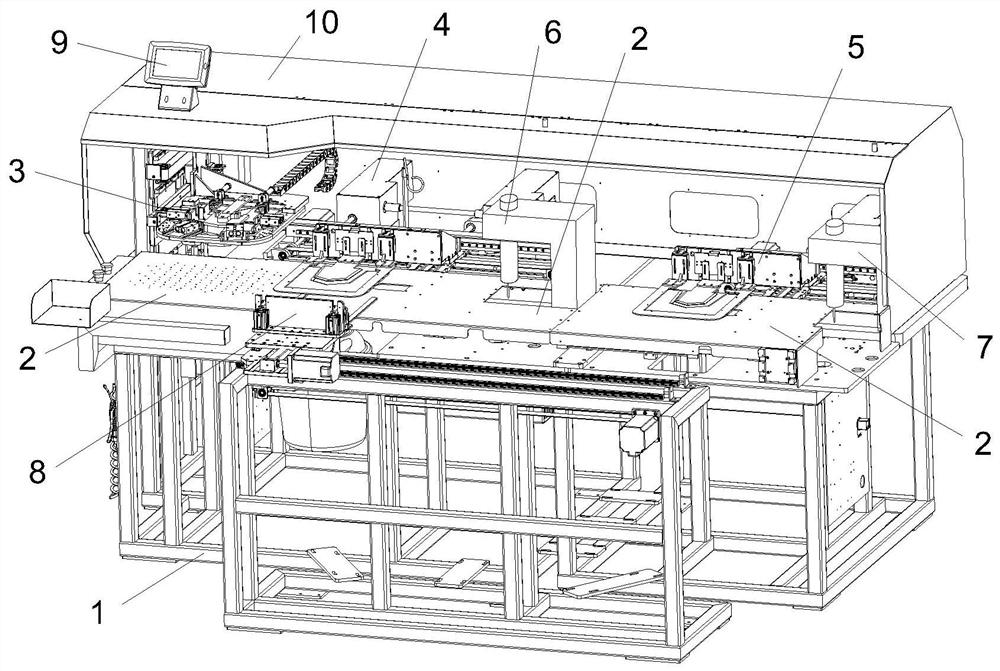

Double-head pocket patching machine

PendingCN111809318AImprove sewing precisionHigh degree of automationWork-feeding meansNumerical controlEngineering

The invention discloses a double-head pocket patching machine, and relates to the field of sewing equipment. The machine comprises a rack, wherein a sewing working plane is fixedly installed on the rack, a pocket feeding device, a first sewing transportation device and a second sewing transportation device are fixedly installed on the rack in sequence from left to right, the upper surface of a sewing working plane is provided with a first sewing machine and a second sewing machine, the first sewing machine is arranged between the first sewing transportation device and the second sewing transportation device, and the second sewing machine is arranged on the right side of the second sewing transportation device; the front part of the pocket feeding device, the front part of the first sewingtransportation device, and the front part of the second sewing transportation device are all arranged above the sewing working plane, the front side of the rack is fixedly provided with a material conveying device, and the rear portion of the material conveying is arranged above the sewing working plane; and a numerical control panel used for correspondingly controlling the pocket feeding device,the first sewing transportation device, the second sewing transportation device, the first sewing machine, the second sewing machine and the material conveying are further fixedly installed on the rack.

Owner:东莞乾清自动化缝纫设备有限公司

Collar pressing die, collar sewing equipment and collar sewing method

PendingCN112806652AImprove sewing precisionReduce work intensityGarmentsClothes making applicancesMechanical engineeringIndustrial engineering

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Head installation structure of a template sewing machine

ActiveCN104674474BEasy to replaceImprove sewing precisionSewing-machine elementsEngineeringMachining process

The invention provides a head mounting structure for a template sewing machine, and belongs to the technical field of sewing machines. The problem of noise produced by the vibration of a working bedplate and a rack of a conventional template sewing machine is solved. The head mounting structure for the template sewing machine comprises a base in a rack, wherein a head is fixedly arranged on the base, and extends from the upper surface of a working bedplate; a support part positioned below the base is arranged on the rack; a plurality of support cushion blocks are arranged between the base and the support part; each support cushion block is positioned on the support part, and elastically contacts with the base. According to the head mounting structure for the template sewing machine, the head is fixedly arranged on the base, and then the base is arranged on the rack through the support cushion blocks to realize floating connection between the head and the rack, so that the working bedplate of the template sewing machine is more stable in a machining process, and the sewing accuracy of the template sewing machine is improved.

Owner:浙江耐拓机电科技有限公司

Mold for sewing back waist band

The invention discloses a mold for sewing a back waist band, and relates to the technical field of sewing machines. The mold comprises a first guiding piece and a second guiding piece, the first guiding piece comprises a base plate, a semi-U-type hook with a rightward opening is arranged on the left side of the base plate, the second guiding piece comprises a support, the upper face of the support is provided with an upper U-type hook with a leftward opening, the lower face of the support is provided with a lower U-type hook with a leftward opening, and a lower half U-type hook body of the lower U-type hook is fixed on the base plate. The mold is simple in structure and low in manufacturing cost, the steps of ironing, seam reversing, seam allowance and the like are omitted, an open thread is directly sewed, the sewing quality can be guaranteed, the sewing speed is greatly quickened, and the work efficiency is greatly improved.

Owner:JIHUA 3534 CLOTHING

A dust-proof device for a sewing machine

ActiveCN104562485BImpede normal functioningExtended service lifePortable coversEngineeringSewing machine

The invention provides a dustproof device for a sewing machine, belongs to the technical field of manufacturing of sewing machines, and aims at solving the problem of large space for the dustproof device and easy collision of the existing sewing machine. The dustproof device for the sewing machine is characterized in that the sewing machine comprises a workbench panel and a die plate transmission assembly; an elongated guide hole which passes through the workbench panel is formed in the workbench panel; the die plate transmission assembly can move along the guide hole; the dustproof device comprises a dustproof plate and a reversing structure; the reversing structure is fixedly connected to one side of the workbench panel; the dustproof plate is positioned in the guide hole, and the width of the dustproof plate is matched with that of the guide hole; one end of the dustproof plate is fixedly connected with the die plate transmission assembly and while the other end of the dustproof plate passes through the reversing structure; the moving direction of the dustproof plate can be changed by the reversing structure. The dustproof device for the sewing machine has the advantages of being good in dustproof effect and small in space used.

Owner:ZHEJIANG ZOJE SEWING MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com