An automatic bag sticking machine

A pocketing machine, automatic technology, applied in the direction of the cloth pressing mechanism, cloth feeding mechanism, sewing machine components, etc., can solve the problems of the unloading board hitting other equipment, mechanical damage, etc., and achieves the degree of automation and is easy to control and reduce Bearing capacity and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

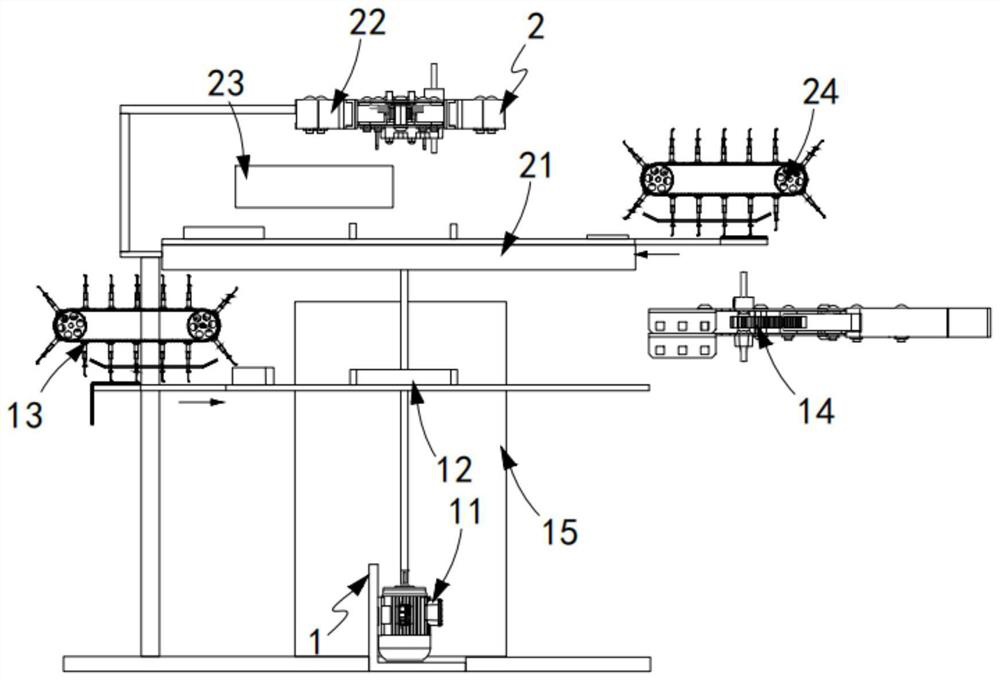

[0048] like figure 1 As shown, an automatic bag patching machine, comprising:

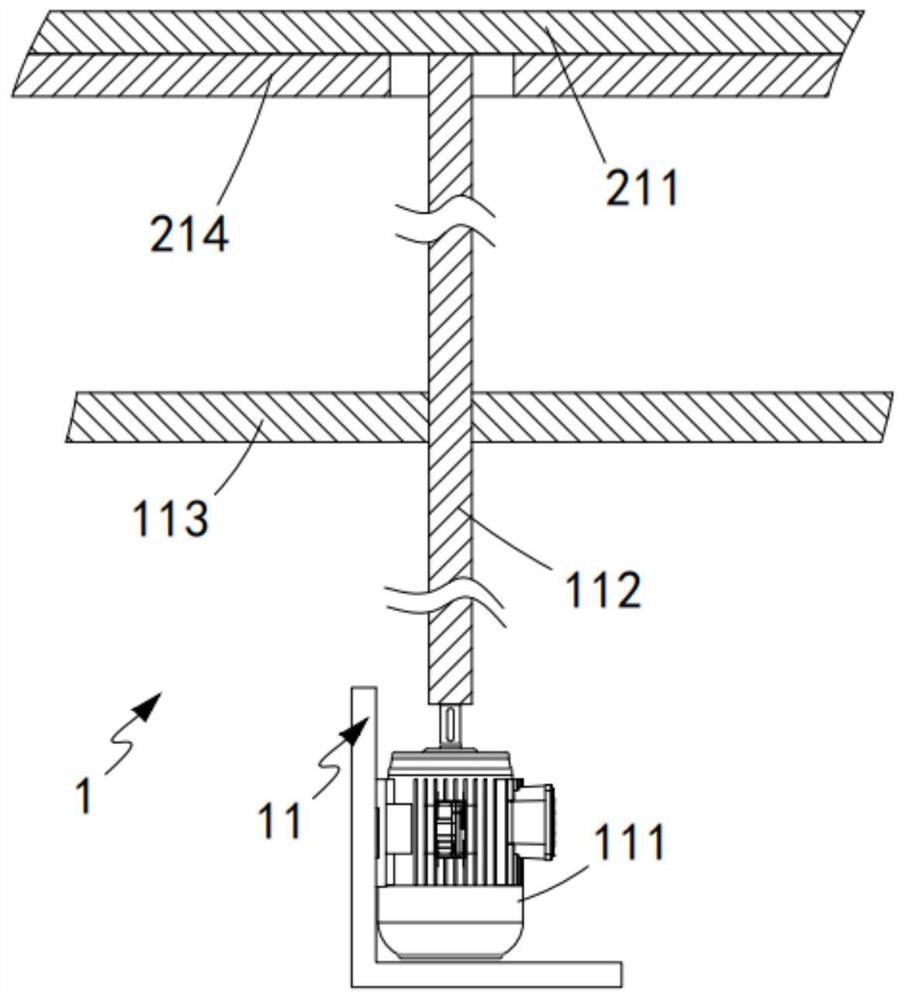

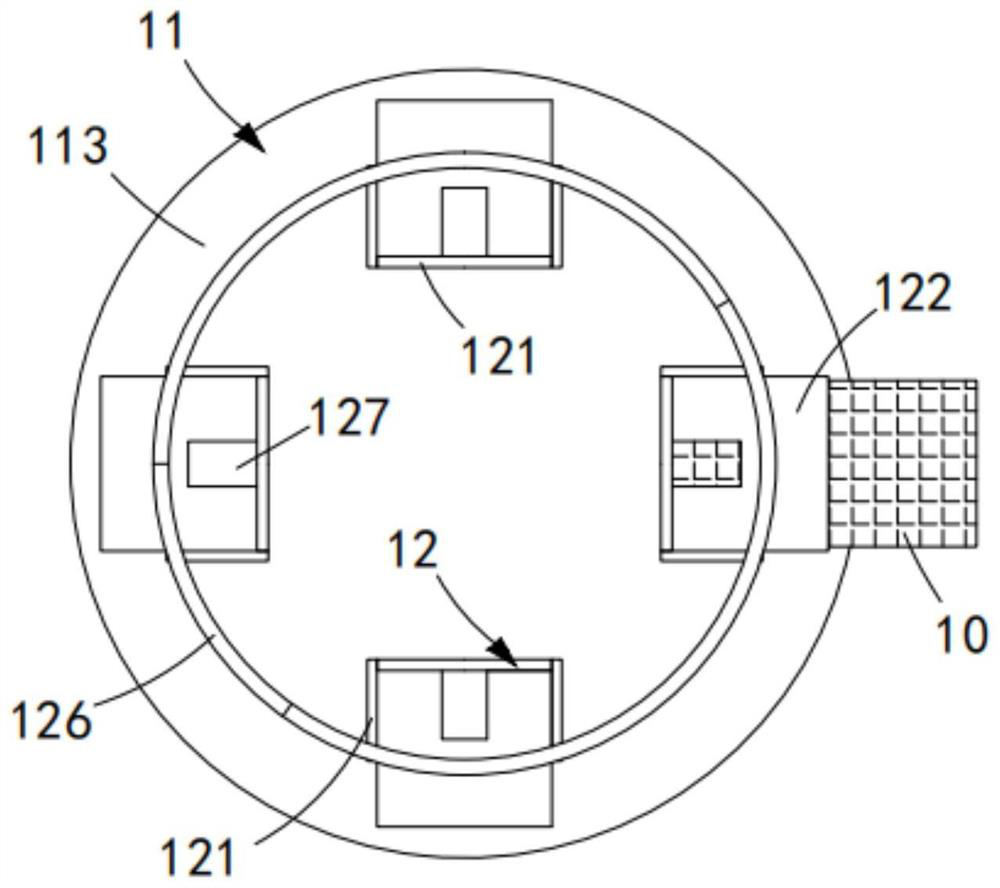

[0049] A station switching mechanism 1, the station switching mechanism 1 includes a drive assembly 11 and a first bearing that is arranged in several groups at equal intervals along the circumferential direction of the drive assembly 11 and performs intermittent circular rotation under the drive of the drive assembly 11 Assembly 12, the drive assembly 11 is sequentially provided with a feeding station 101, a bag receiving station 102, a bag sticking station 103 and an output station 104 along its circumferential direction;

[0050] The hemming mechanism 2 is arranged above the station switching mechanism 1 , and the hemming mechanism 2 includes a second bearing assembly 21 and a hemming assembly 22 arranged on the second bearing assembly 21 and a transfer assembly 23 arranged on the second carrying assembly 21, the second carrying assembly 21 is sequentially provided with a hemming station 201, a...

Embodiment 2

[0098] like Figure 16 to Figure 17 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

[0099] further, as Figure 16 to Figure 17 As shown, the output assembly 15 includes a lead-out track 151 and a collection box 152 arranged below the output end of the lead-out track 151, and the lead-out track 151 and the trouser leg 10 hang down on the drive assembly 11 part of the fitting arrangement;

[0100] The lead-out rail 151 is located between the pocket placement station 103 and the output station 104 , and the distance from the lead-out rail 151 to the center of the drive assembly 11 increases.

[0101] In this embodiment, the work of automatically pulling out the rear trouser legs of the patch pocket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com