Full-automatic sleeping bag sewing machine

A sewing machine, fully automatic technology, applied in the field of sewing machines, can solve the problems that the machine vibration will become larger, the width and mechanical structure will be large, and the sewing speed cannot be improved, and the effect of improving stability and small overall structure size can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

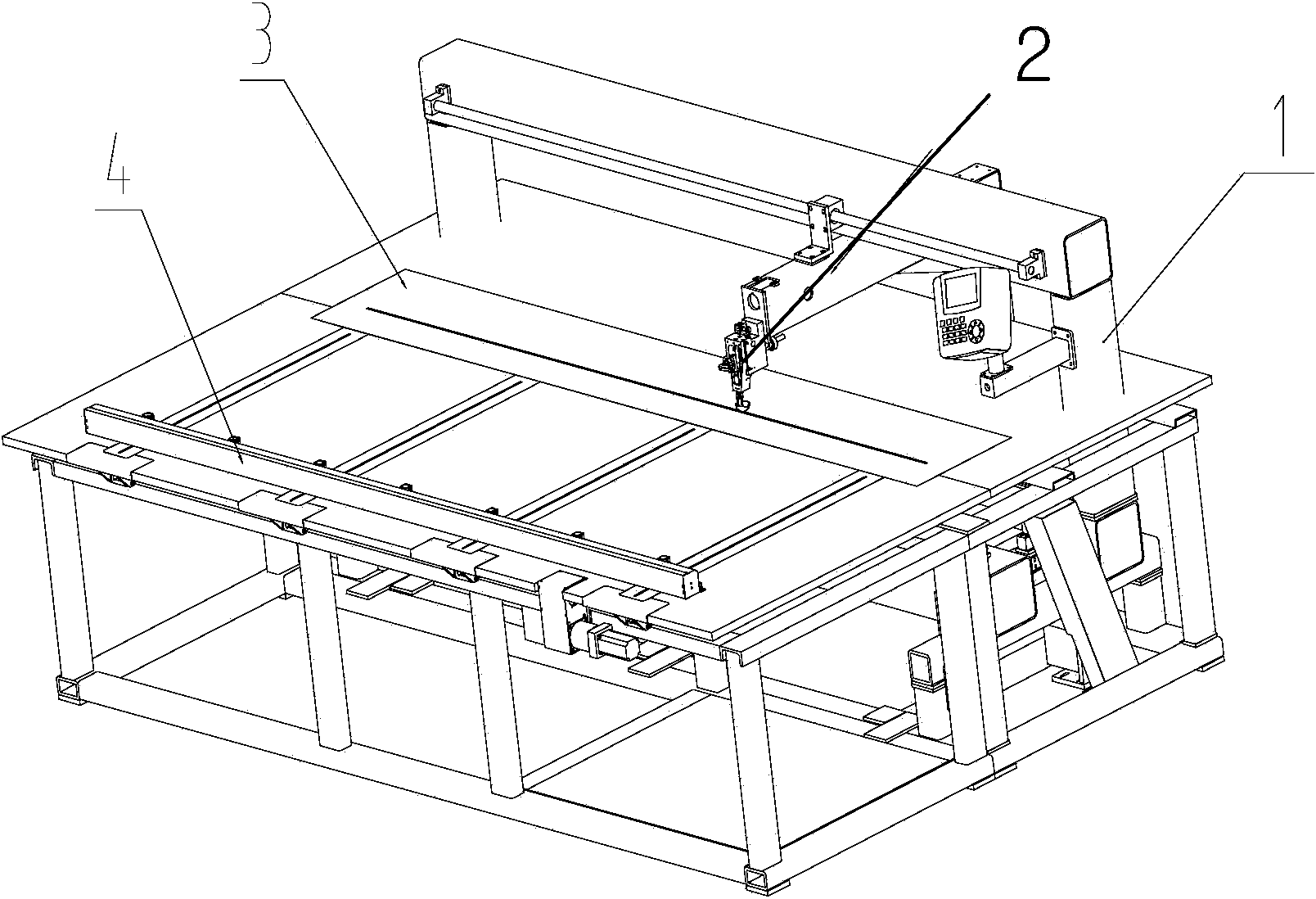

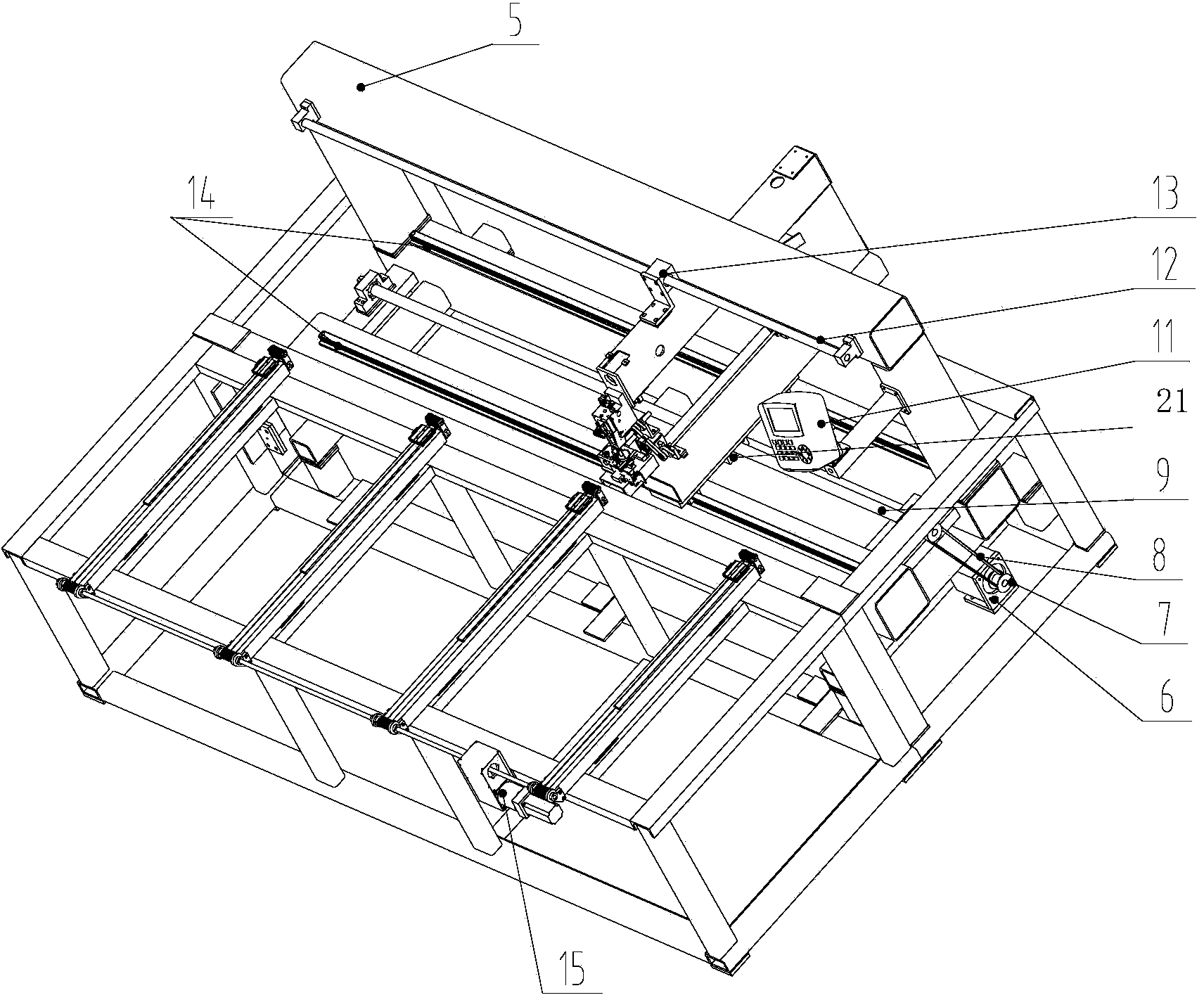

[0016] see Figure 1 to Figure 4 , the fully automatic sleeping bag sewing machine of the present invention comprises a frame 1, a machine head 2 capable of moving in the X direction, a platen 3 mounted on the frame 1 and a frame beam 5, a machine head mounted on the platen 3 and capable of moving in the Y direction. Automatic sewing frame 4 and the computer control box 11 that are installed on frame beam 5 one sides.

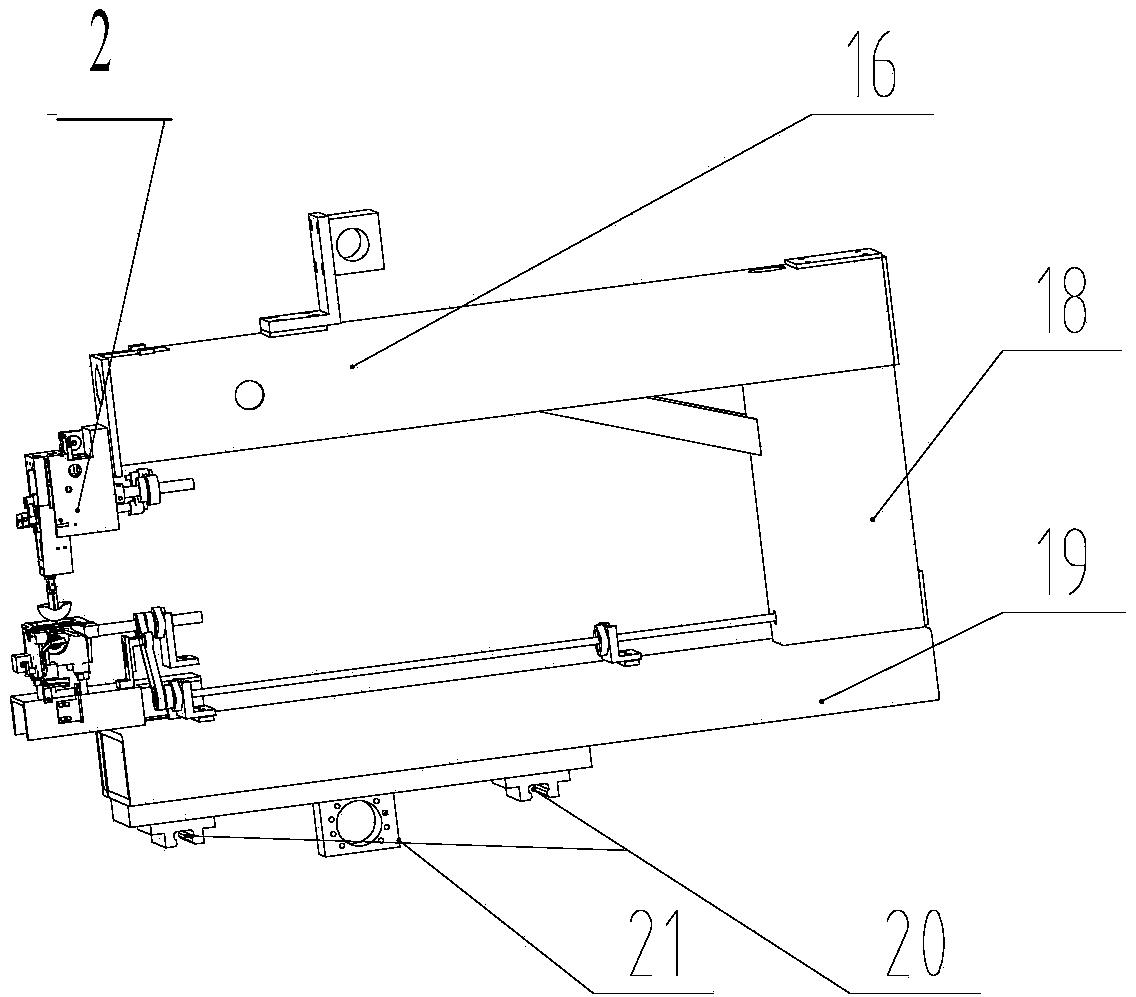

[0017] The machine head 2 is fixedly connected on the "]" shaped cantilever structure formed by the upper beam 16, the vertical beam 18 and the lower beam 19 of the machine head, and the bottom of the lower beam 19 of the machine head is provided with a screw nut 21 and two linear guide rail seats 20, the frame 1 is provided with a lead screw 9 that is connected to the screw nut 21, and the frame 1 is also provided with two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com