Cloth pressuring device of sewing machine

A cloth pressing device and sewing machine technology, which is applied in the direction of sewing machine components, cloth pressing mechanism, sewing equipment, etc., can solve the problems of inability to convey cloth, reduce operating efficiency, and uneven left and right deviation of cloth, so as to prevent needle pitch confusion and prevent damaged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

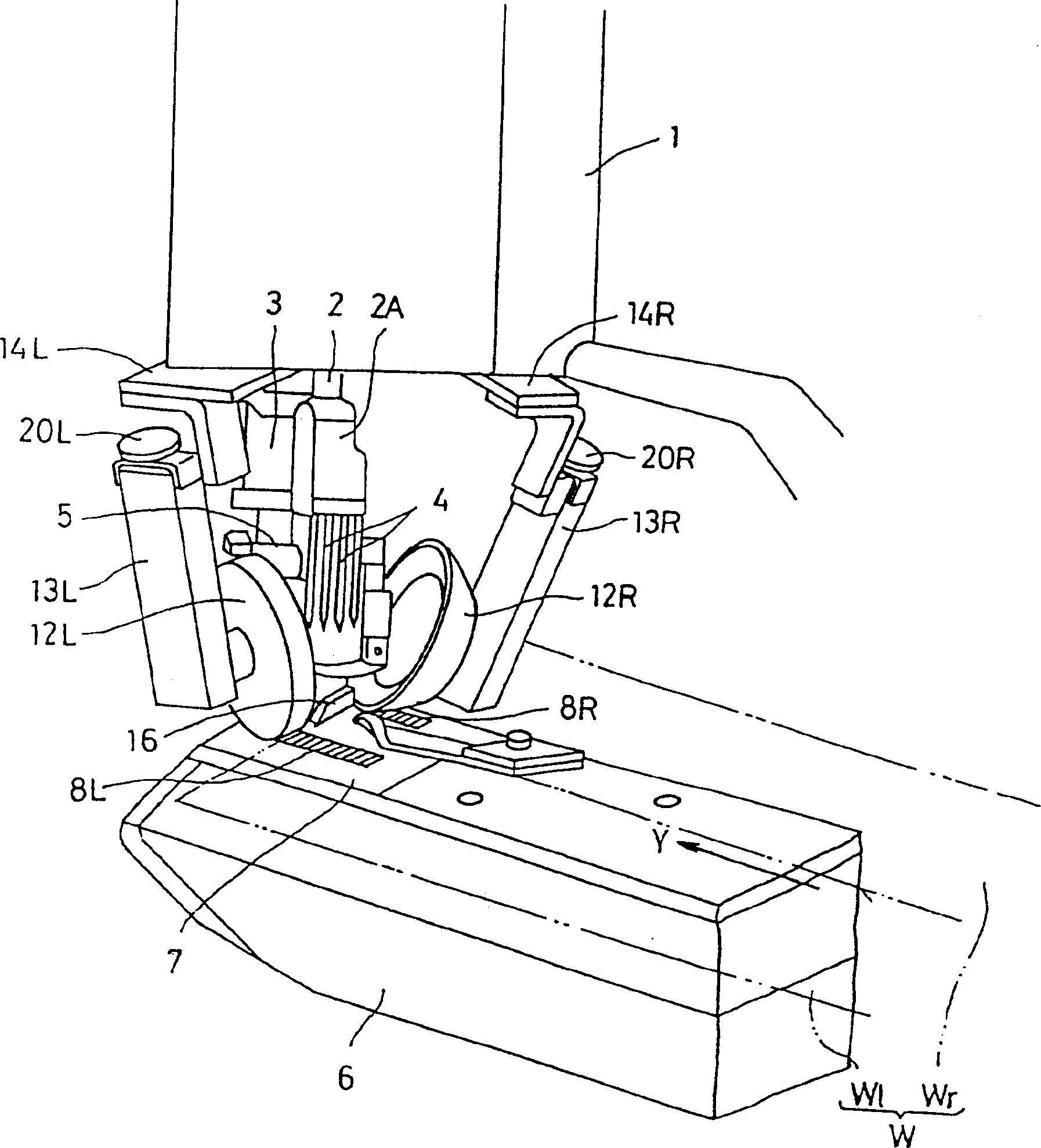

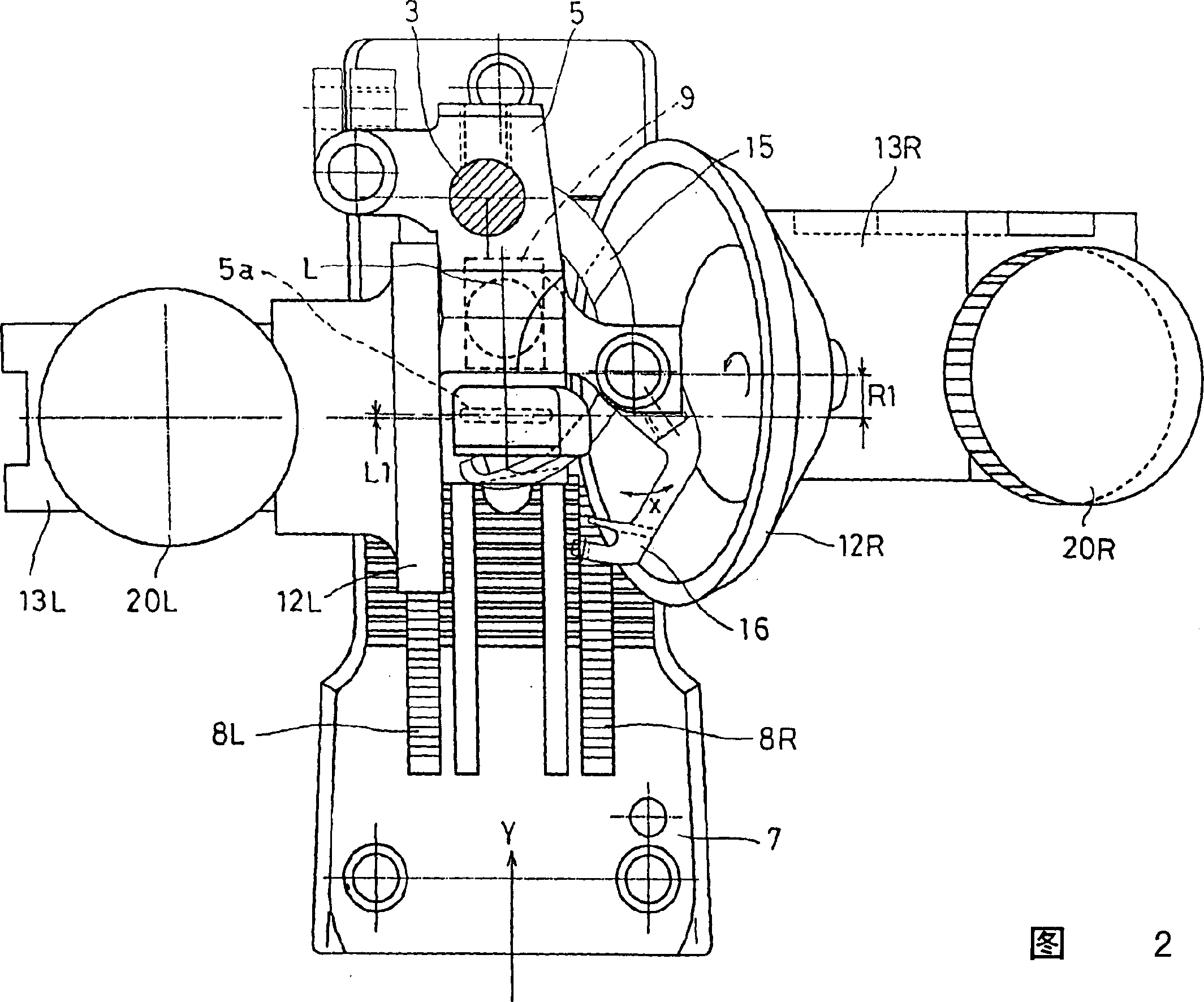

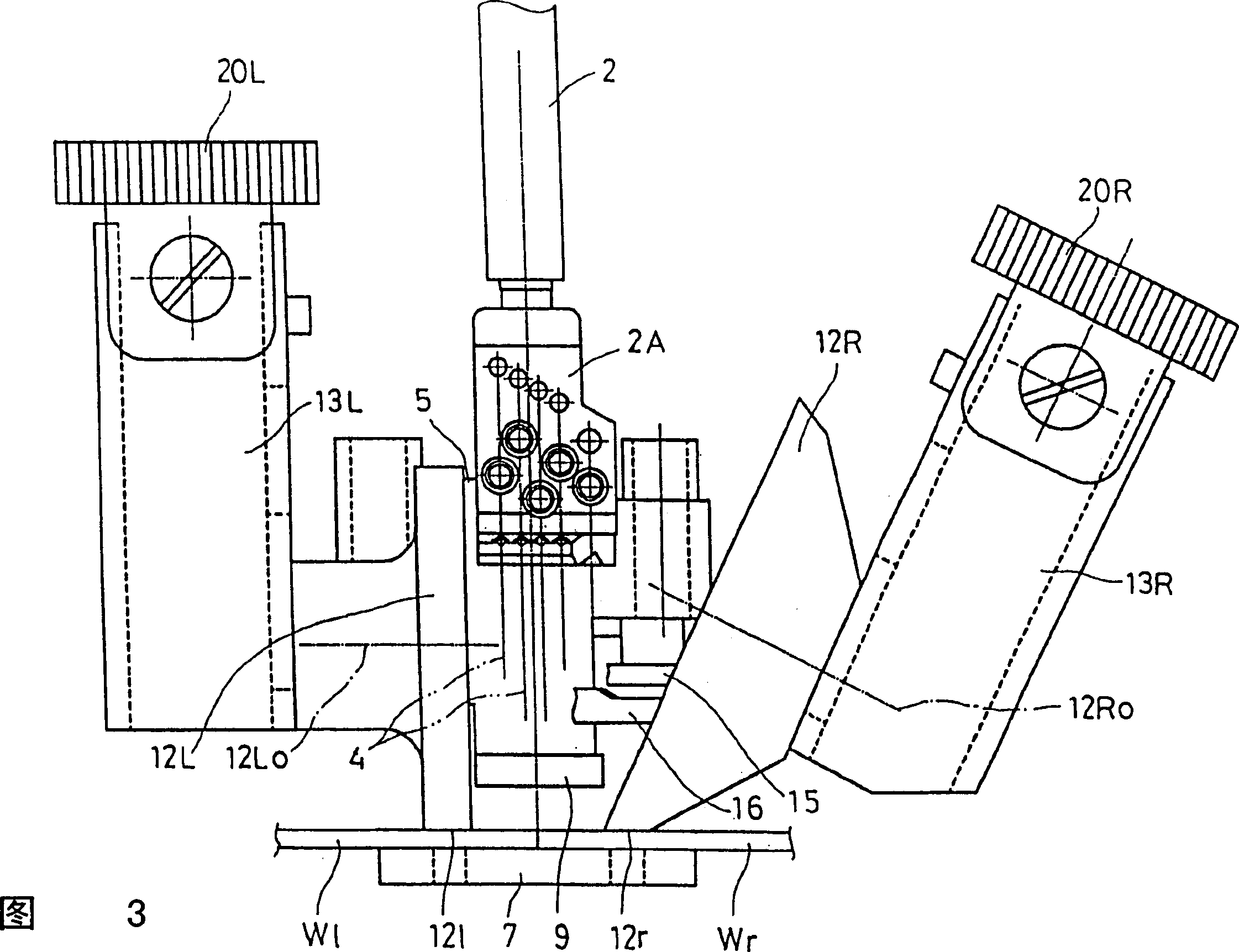

[0030] figure 1 It is a perspective view of the vicinity of the needle drop part of the cantilever sewing machine output by the cloth pressing device in the first embodiment of the present invention. At the tip of the sewing machine arm frame 1, it is juxtaposed front and back along the sewing forward direction Y and can freely reciprocate up and down. The needle bar 2 and the pressing bar 3 are supported droopingly. At the same time, several needles 4 are installed at the lower end of the needle bar 2 through the needle clamp 2A, and the lower end of the pressing bar 3 is fixedly supporting the presser foot body 5 .

[0031] On the other hand, a needle lifter 7 is fixed on the narrow tube type cylinder head 6. At the same time, in the cylinder head 6 at the lower part of the needle lifter 7, in addition to a pair of movable conveying teeth 8L, 8R, there is also a Place the parts for forming loops or sutures of the conveying mechanism (because these are well known, their detai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com